Environmental protection recycling method of deserted brominated flame retardant plastics

A recovery method and a brominated flame retardant technology are applied in the removal of solid waste, special forms of dry distillation, coke ovens, etc., to achieve the effects of low cost, reduced resource cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

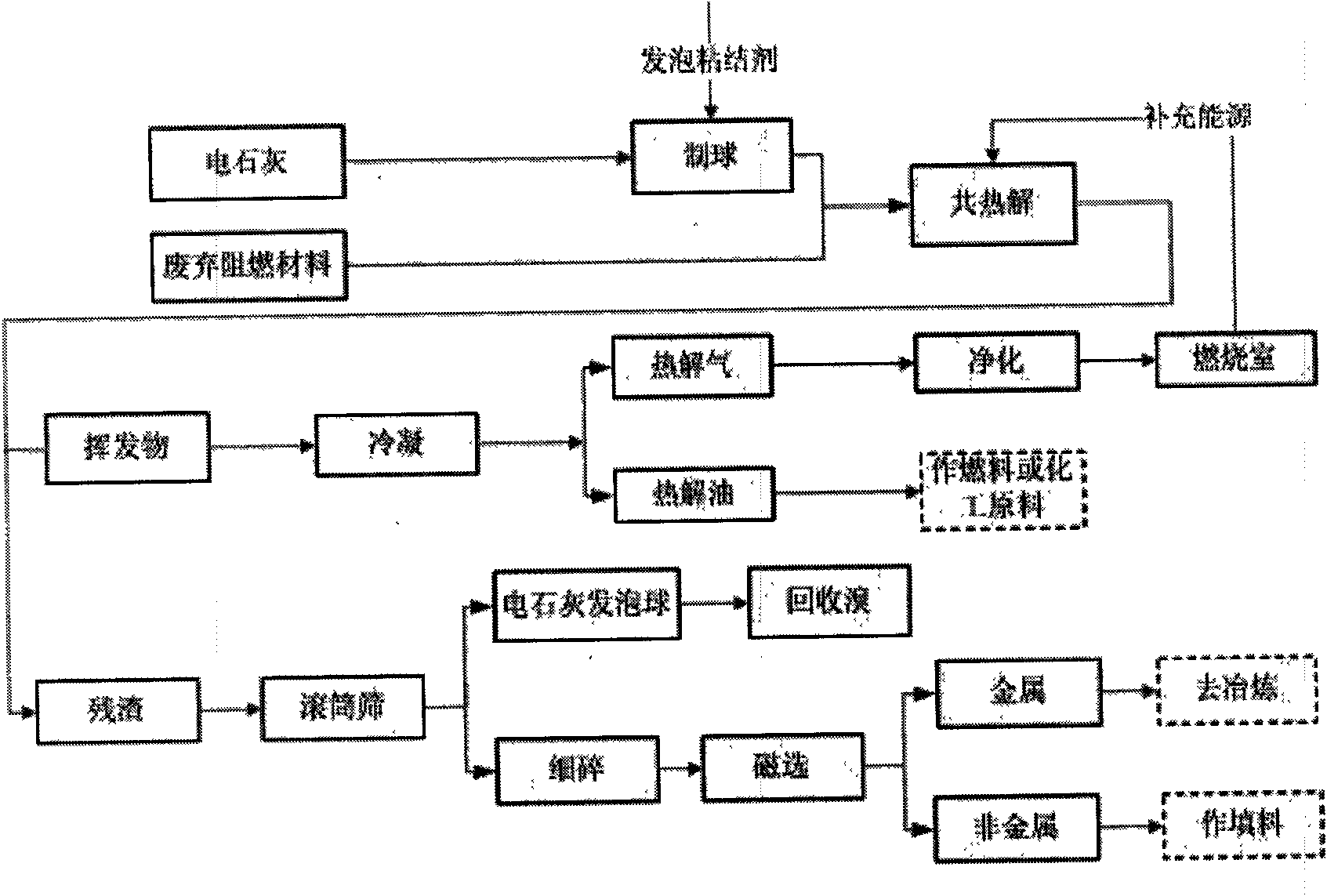

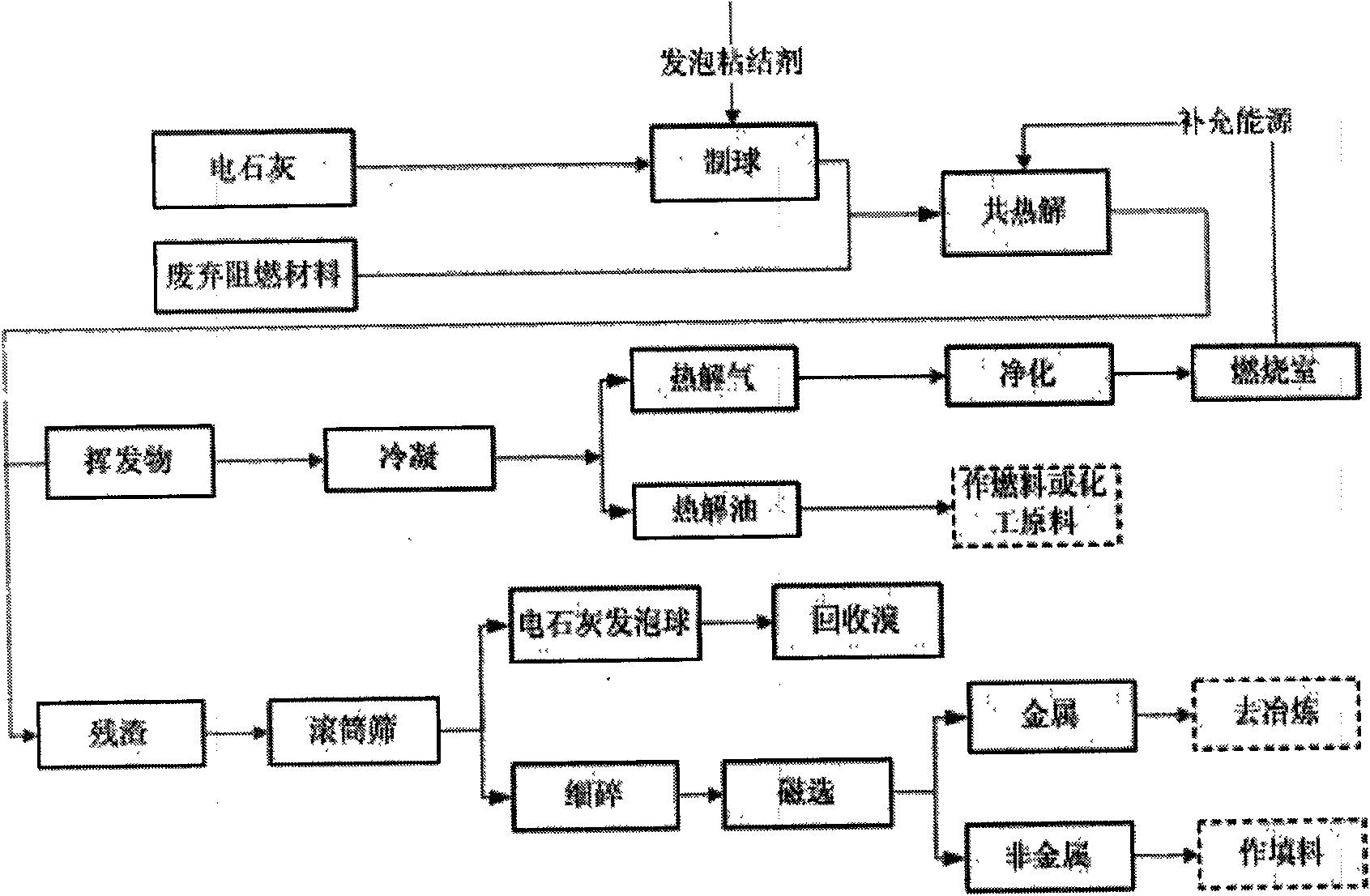

[0028] Such as figure 1 Shown, carry out the inventive method according to the following steps:

[0029] 1) Grind relatively dry calcium carbide with a moisture content of not more than 10% to 80-100 mesh, and measure the moisture content of each batch of calcium carbide for batching; then mix calcium carbide and clay in a weight ratio of 1:0.3 Mix, make the bead that diameter is less than 0.5cm with the ball making machine (the molding pressure of ball making machine is 20MPa) and ventilate and dry, guarantee moisture content2 , which will not be broken after pyrolysis so as to facilitate separation and recovery;

[0030] 2) Coarsely crushing waste brominated flame-retardant plastics to fragments whose size meets the requirements for feeding the pyrolysis furnace;

[0031] 3) Next, mix the calcium carbide pellets obtained in step 1) and the plastic fragments obtained in step 2) in a weight ratio of 4:1, and then feed them into a feed pyrolysis furnace in an inert atmosphere ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com