Nanoscale size structure measuring method and device

A measurement method, nano-scale technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to obtain clear imaging, unable to meet the requirements of accurate measurement of key dimensions of nano-scale structures, and achieve rapid geometric feature parameters, Promotes the effect of expanding applications and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

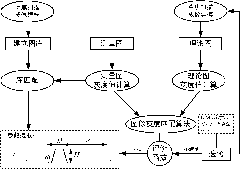

[0022] Below in conjunction with accompanying drawing and example the principle of the inventive method and working process are described in further detail:

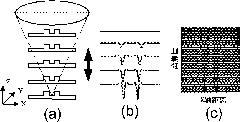

[0023] (1) After the white light beam is filtered and polarized, it is projected vertically onto the surface of the sample containing nanoscale structures, and the wavelength of the linearly polarized beam projected onto the surface of the sample is 400-600nm.

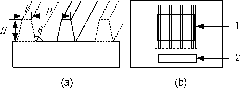

[0024] Taking the measurement process of the isolated line array structure as an example, the isolated line array structure is as follows figure 1 As shown in (a), the geometry parameters of the nanoscale structure to be measured include line width D, period P, depth H and side wall angle θ.

[0025] (2) The projected beam is reflected by the surface of the sample, and the reflected signal is received by a charge-coupled device (CCD) placed on the conjugate surface of the sample, and the microscopic imaging map of the nanoscale structure is calculated.

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com