Photovoltaic glass plated with double-layer antireflection film and preparation method thereof

A technology of photovoltaic glass and anti-reflection film, which is applied in the field of photovoltaic glass and its preparation, can solve the problems of affecting the output power of photovoltaic modules of solar cells, large-scale preparation of photovoltaic glass, and low precision of film thickness control, and achieves low process cost and advantages Remarkably, the effect of improving the anti-reflection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

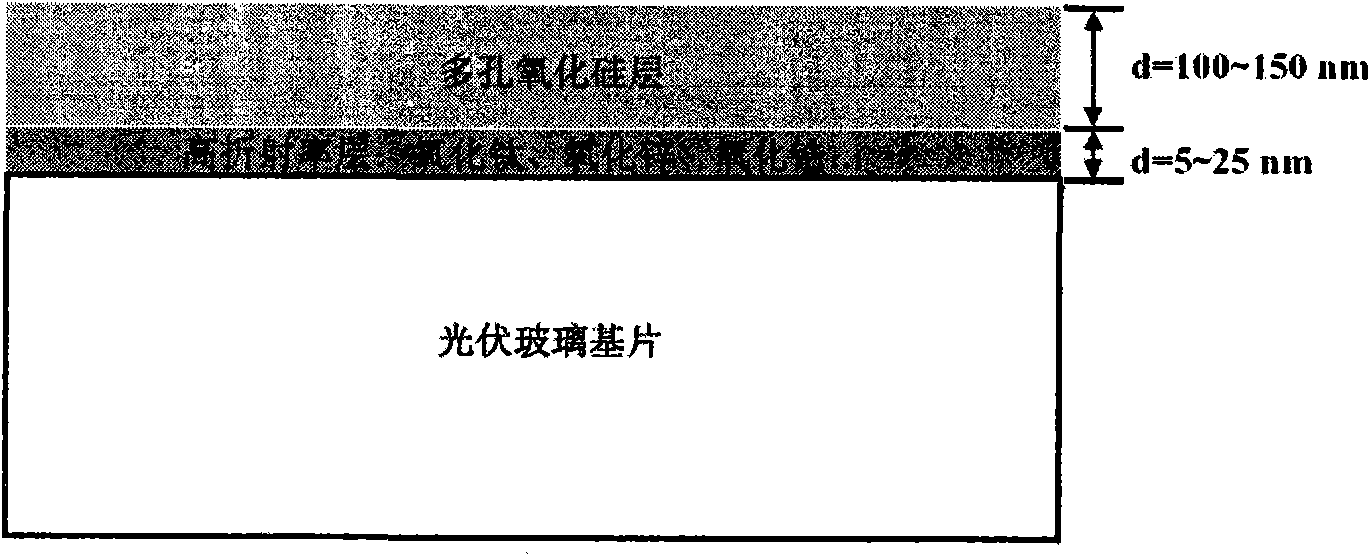

[0038] Mix and heat 0.1mol water, 0.035mol HCl and 1.5mol ethanol with stirring. When the temperature reaches the set temperature of 30°C, quickly add 0.0235mol tetrabutyl titanate and mix and stir for 30 hours to obtain a stable and transparent titanium oxide sol, which is aged for 3 days stand-by.

[0039] With the photovoltaic glass as the substrate, the aging titanium oxide sol is coated on the surface of the photovoltaic glass by the pulling method. The pulling speed is 2mm / s, and the number of pulling is 1 time. Photovoltaic glass with titanium dioxide gel film. The photovoltaic glass coated with the transparent titanium dioxide gel film prepared above is heat-treated in the air at 550°C for 1 minute, and a photovoltaic glass sample coated with a titanium dioxide film with a thickness of about 20 nm and good adhesion to the film base can be obtained.

[0040] 0.25mol water, 0.078mol NH 3 ·H 2 O and 4.75 mol of absolute ethanol were mixed and heated with stirring. When...

Embodiment 2

[0044] Mix and heat 0.1175mol water, 0.01175mol HCl and 1.175mol ethanol with stirring. When the temperature reaches the set temperature of 30°C, quickly add 0.0235mol tetrabutyl titanate and mix and stir for 30 hours to obtain a stable and transparent titanium oxide sol, which is aged for 3 days stand-by.

[0045] With the photovoltaic glass as the substrate, the aging titanium oxide sol is coated on the surface of the photovoltaic glass by the pulling method. The pulling speed is 2mm / s, and the number of pulling is 1 time. Photovoltaic glass with titanium dioxide gel film. The above-mentioned photovoltaic glass coated with transparent titanium dioxide gel film is heat-treated in air at 200° C. for 3 hours to obtain a photovoltaic glass sample coated with a titanium dioxide film with a thickness of about 25 nm and good adhesion to the film base.

[0046] Mix 0.05 mol of water, 0.05 mol of hydrochloric acid and 3 mol of absolute ethanol with stirring and heating. When the tem...

Embodiment 3

[0050] Mix and heat 0.0235 mol of water, 0.05875 mol of acetic acid and 5.875 mol of ethanol. When the temperature reaches the set temperature of 30°C, quickly add 0.0235 mol of tetrabutyl titanate and mix and stir for 30 hours to obtain a stable and transparent titanium oxide sol, which is aged for 3 days. stand-by.

[0051] With the photovoltaic glass as the substrate, the aging titanium oxide sol is coated on the surface of the photovoltaic glass by the pulling method. The pulling speed is 2mm / s, and the number of pulling is 1 time. Photovoltaic glass with titanium dioxide gel film. The above-mentioned photovoltaic glass coated with transparent titanium dioxide gel film is heat-treated in the air at 300°C for 0.5 hour, and a photovoltaic glass sample coated with a titanium dioxide film with a thickness of about 5 nm and good adhesion to the film base can be obtained.

[0052] Mix 0.05 mol of water, 0.15 mol of hydrochloric acid and 4.75 mol of absolute ethanol with stirrin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com