Radiation-sensitive polyorganosiloxane, method for producing the same and liquid crystal aligning agent

A technology of polyorganosiloxane and liquid crystal aligning agent, applied in liquid crystal materials, nonlinear optics, chemical instruments and methods, etc., can solve the problems of unstable moisture of hydrogen silsesquioxane, and achieve good pretilt angle performance. , the effect of good liquid crystal alignment energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

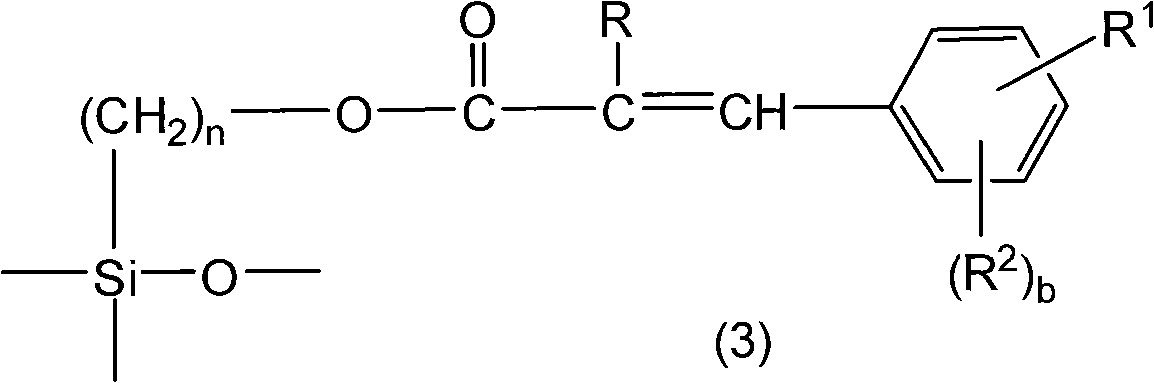

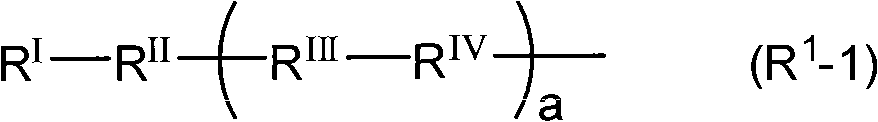

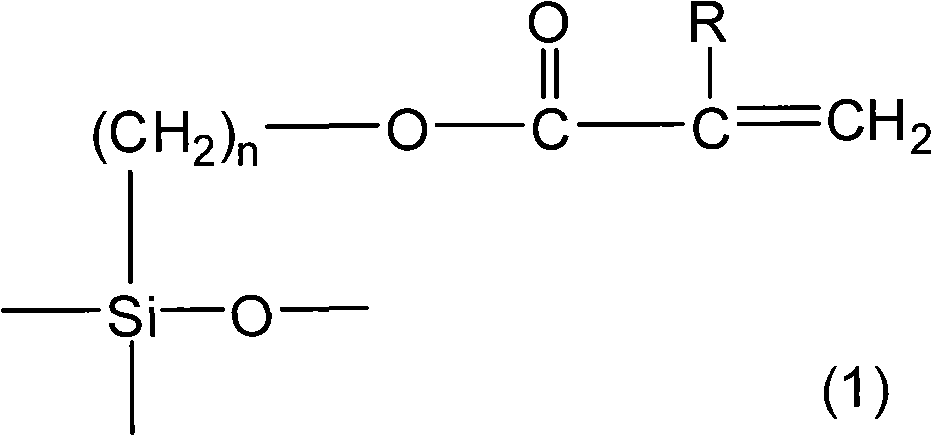

[0049] The method for preparing radiation-sensitive polyorganosiloxane of the present invention is characterized in that a polyorganosiloxane having a structure represented by the above formula (1) (hereinafter referred to as "polyorganosiloxane having (meth)acryloyloxy) Oxyane") and the compound represented by the above formula (2) (hereinafter referred to as "compound (2)") react in the presence of a heavy metal compound or a heavy metal complex.

[0050]

[0051] As the polyorganosiloxane having the structure represented by the above formula (1), for example, a polyorganosiloxane having a repeating unit represented by the following formula (1'), a hydrolyzate and a condensate of the hydrolyzate are selected At least one of the formed groups,

[0052]

[0053] In formula (1'), R and n are each the same as defined in formula (1) above, and Y 1 It is a hydroxyl group, an alkoxy group having 1 to 10 carbon atoms, an alkyl group having 1 to 20 carbon atoms, or an aryl group having 6 ...

Synthetic example 1

[0150] Synthesis Example 1 (Synthesis of Compound (2-4-1))

[0151] The compound (2-4-1) was synthesized according to the following synthetic route 1.

[0152]

[0153] Synthetic Route 1

[0154] Add 91.3g of 4-hydroxybenzoic acid methyl ester, 182.4g of potassium carbonate and 320ml of N-methyl-2-pyrrolidone to a 1L eggplant-shaped flask. After stirring for 1 hour at room temperature, 99.7g of 4, 4, 4 are added. -Trifluoro-1-iodobutane, stirring at 100°C for 5 hours. After the reaction, reprecipitation was performed with water. 48 g of sodium hydroxide and 400 ml of water were added to the obtained precipitate and refluxed for 3 hours for hydrolysis reaction. After the reaction, the reaction mixture was neutralized by adding hydrochloric acid, and the formed precipitate was recrystallized with ethanol to obtain 102 g of white crystals of the compound (2-4-1A).

[0155] Take 23 g of the compound (2-4-1A) into the reaction vessel, add 200 ml of thionyl chloride and 144 μL of N,N-d...

Embodiment S-1

[0159] Into a 500ml three-necked flask equipped with a nitrogen introduction tube, a thermometer and a reflux tube, 16.5g of AC-SQ (manufactured by Toagosei Co., Ltd.) and 15.5g of the compound represented by the following formula (2-9-1) ( Compound 2-9-1),

[0160]

[0161] 0.11g of palladium acetate, 0.61g of tris(o-tolyl)phosphine, 27.8ml of triethylamine and 100ml of N,N-dimethylacetamide were reacted at 115°C for 3 hours. After the completion of the reaction, the reaction mixture was filtered to remove insoluble components, ethyl acetate was added to the filtrate, and the resulting organic layer was sequentially washed twice with dilute hydrochloric acid, then washed with water for three times, and then concentrated under reduced pressure. The obtained concentrated liquid was reprecipitated with methanol to obtain 15 g of radiation-sensitive polyorganosiloxane (S-1).

[0162] Carry out the radiation-sensitive polyorganosiloxane (S-1) 1 According to H-NMR analysis, it was conf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com