Climate environment simulation test method

A technology for simulating test and climate environment, applied in the test field, can solve the problems of no large-scale simulation, high cost, high energy consumption, etc., and achieve the effect of reducing test cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

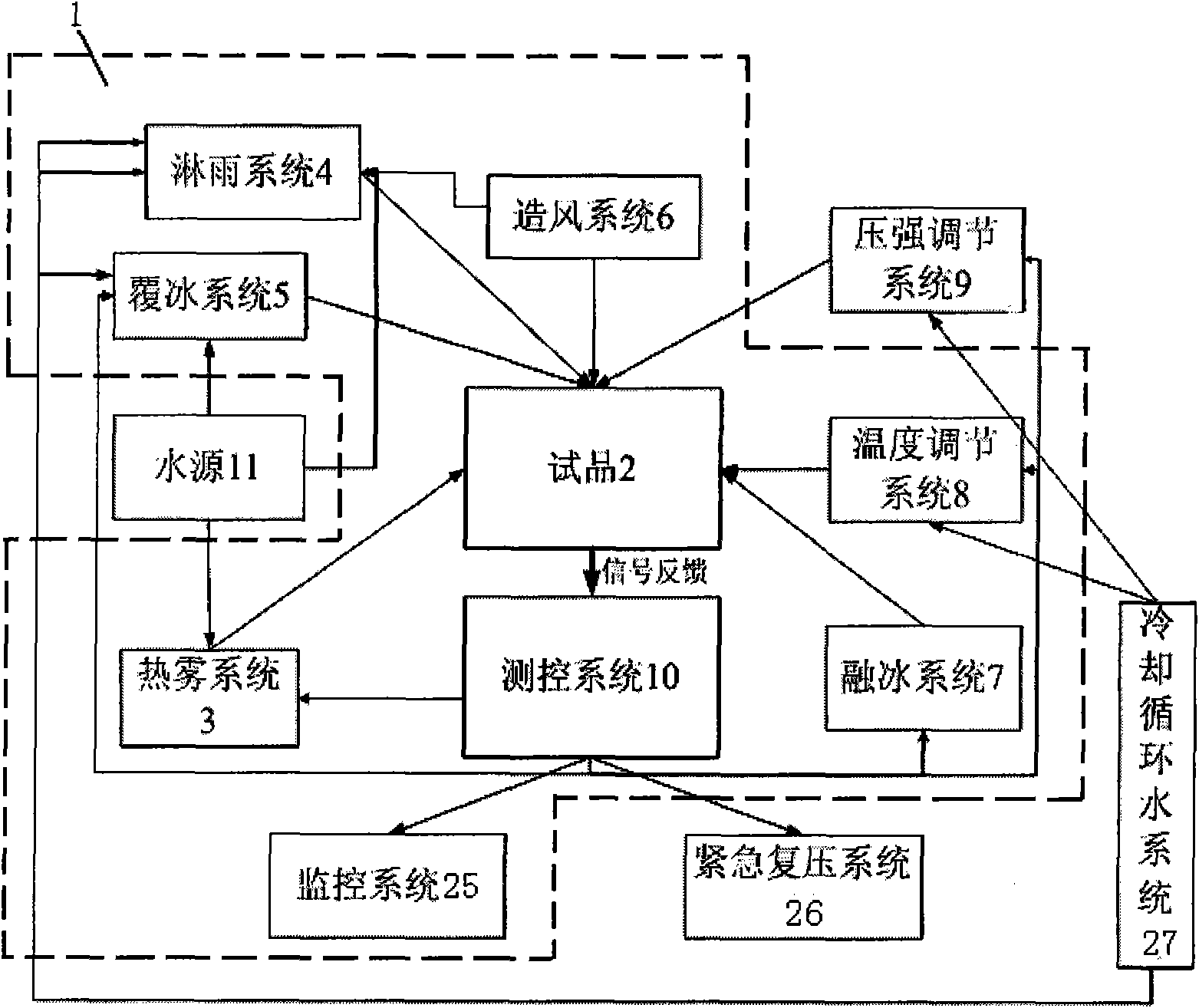

[0016] The method of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0017] like figure 1 As shown, in order to realize the method of the present invention, it is first necessary to set up an environmental simulation cabin 1, and in the environmental simulation cabin 1, a test product 2 connected with UHV electricity, a thermal fog system 3, a rain system 4, and an ice coating system 5 are set up. , wind generation system 6 , ice melting system 7 and temperature adjustment system 8 , a pressure adjustment system 9 , a measurement and control system 10 and a water source 11 are arranged outside the environmental simulation cabin 1 .

[0018] The environmental simulation cabin 1 is a sealed environment simulation test site, and the environmental simulation cabin 1 needs to meet the following requirements:

[0019] Temperature rise rate ΔT / t<1K / h, where: T is absolute temperature, t is time;

[0020] The pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com