Lithium ion power battery cap and welding method thereof

A power battery and welding method technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of lower battery performance level, increased battery resistance, and weak contact, etc., to achieve small contact resistance and low production efficiency , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

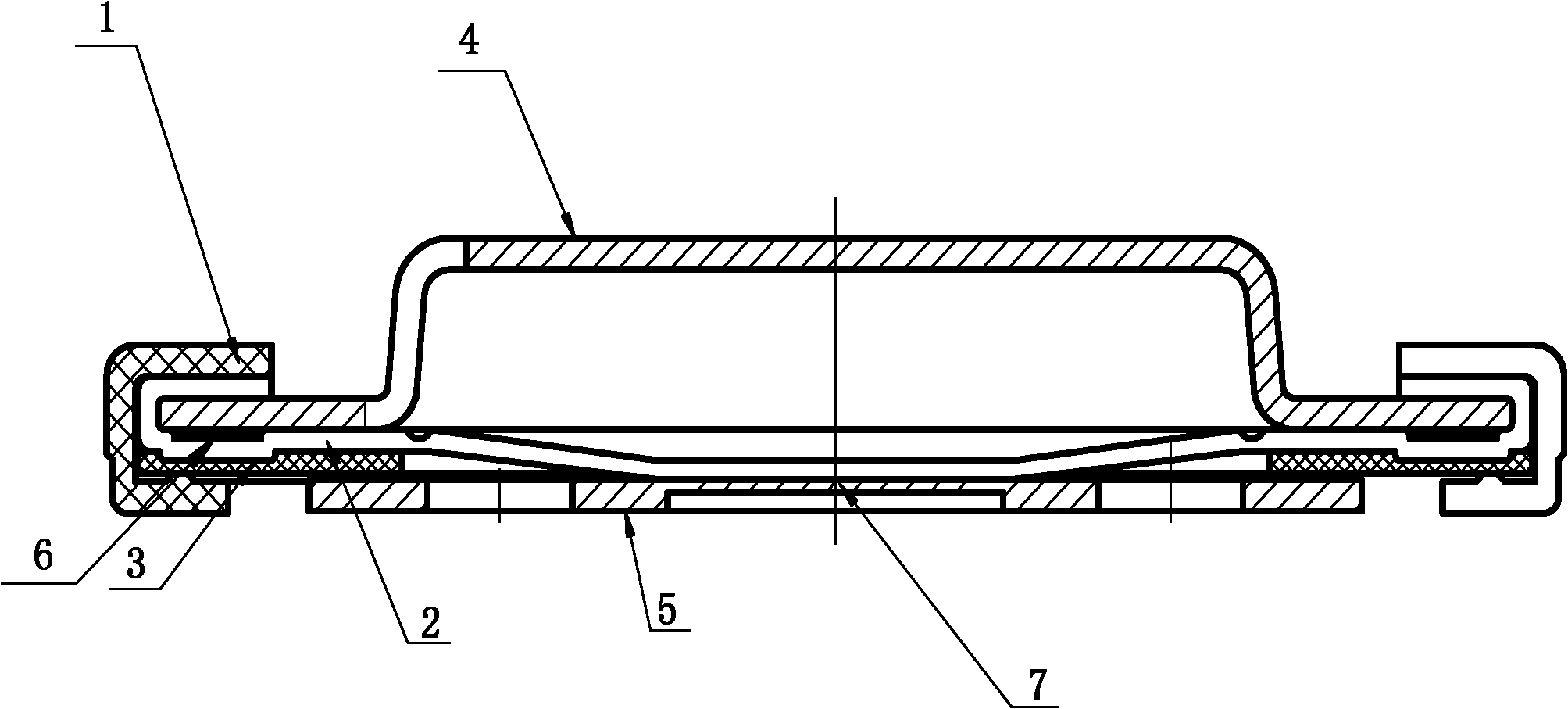

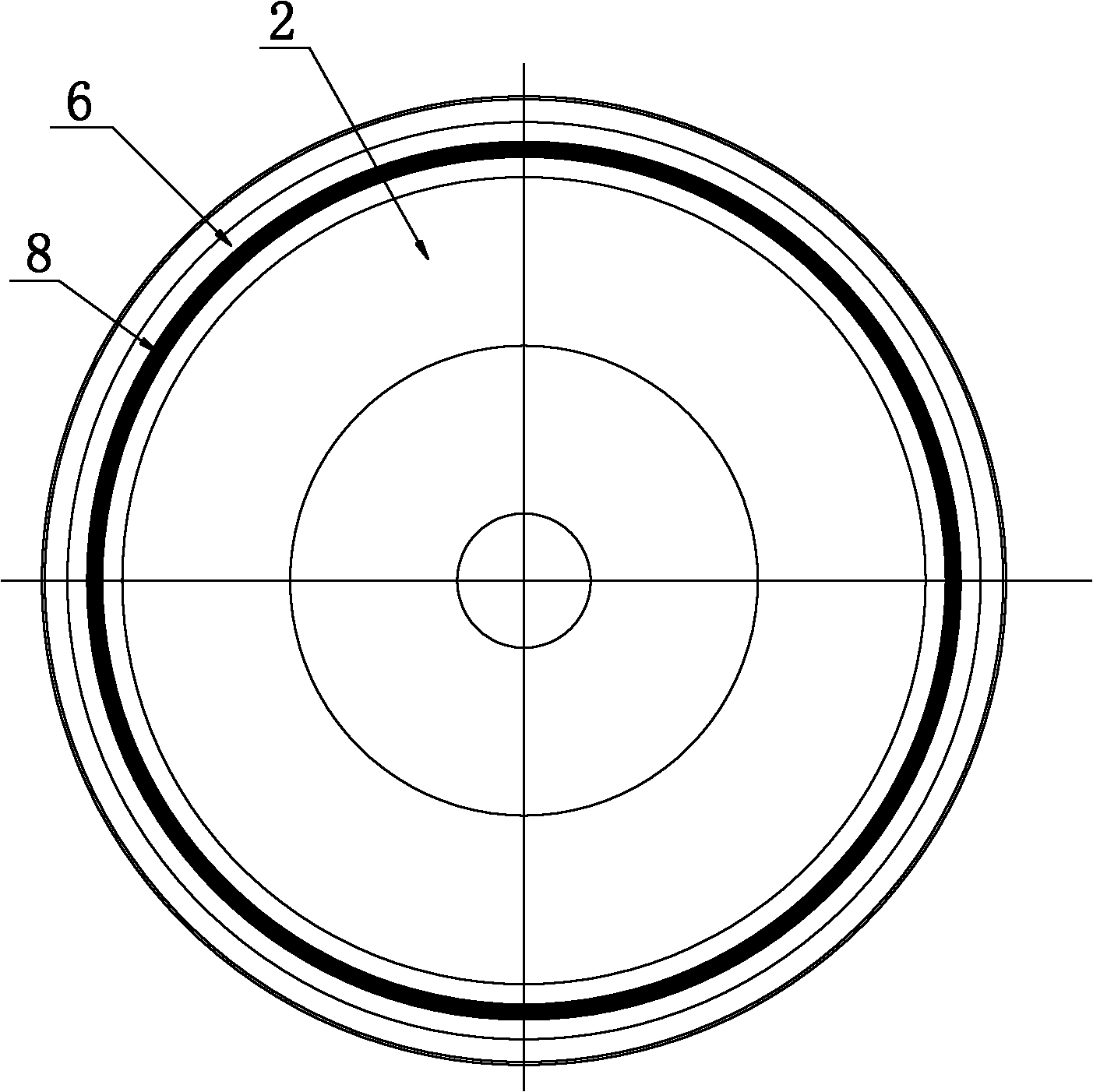

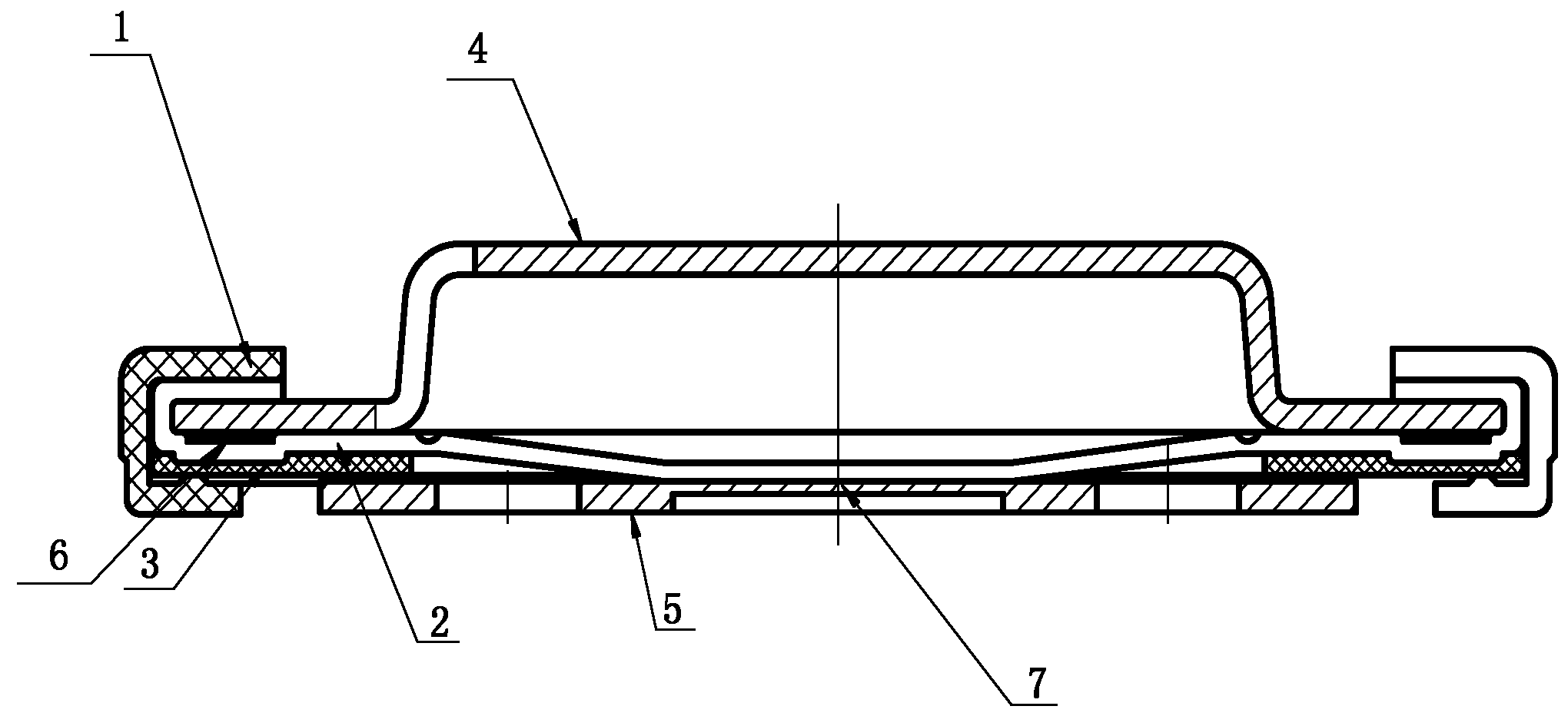

[0017] Embodiment 1 A lithium-ion power battery cap, including a top cover 4, an explosion-proof diaphragm 2, a gasket 3 and a pole plate 5, the top cover 4 is combined with the explosion-proof diaphragm 2, the gasket 3 and the pole plate 5 in sequence, and there are sealing ring 1. The explosion-proof diaphragm 2 has an overall circular welding groove 6, the overall circular welding groove 6 has a depth of 0.05mm and a width of 1.5mm. There are brazing tin wires 8 for the top cover and the explosion-proof diaphragm in the groove, and the top cover and the explosion-proof diaphragm are connected by brazing. The explosion-proof diaphragm and the pole plate have 6 uniform welding spots at the laser welding place 7 .

Embodiment 2

[0018] Embodiment 2 A lithium-ion power battery cap welding method, the top cap, explosion-proof diaphragm, gasket and pole plate are assembled together in sequence, and a sealing ring is added. When processing the top cover and the explosion-proof diaphragm, punch out a circular groove on the top cover and the explosion-proof diaphragm, place brazing tin wire in the groove of the top cover or the explosion-proof diaphragm, and solder the top cover It is welded with the explosion-proof diaphragm to form an integral structure.

[0019] The lithium-ion power battery cap and its welding method have the advantages of novel technology, convenient processing, simple structure, firm contact, small contact resistance, no resistance drift, high safety level, long battery life, wide application range and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com