Microfluidic liquid flow energy-storage single cell and cell stack

A liquid flow energy storage and single-cell technology, which is applied in the direction of fuel cells, secondary batteries, and regenerative fuel cells, can solve the problems of high price of Nafion membrane, restrictions on the practicality of liquid flow energy storage batteries, and increased leakage current loss , to speed up charge and discharge, easy to manufacture, and increase current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

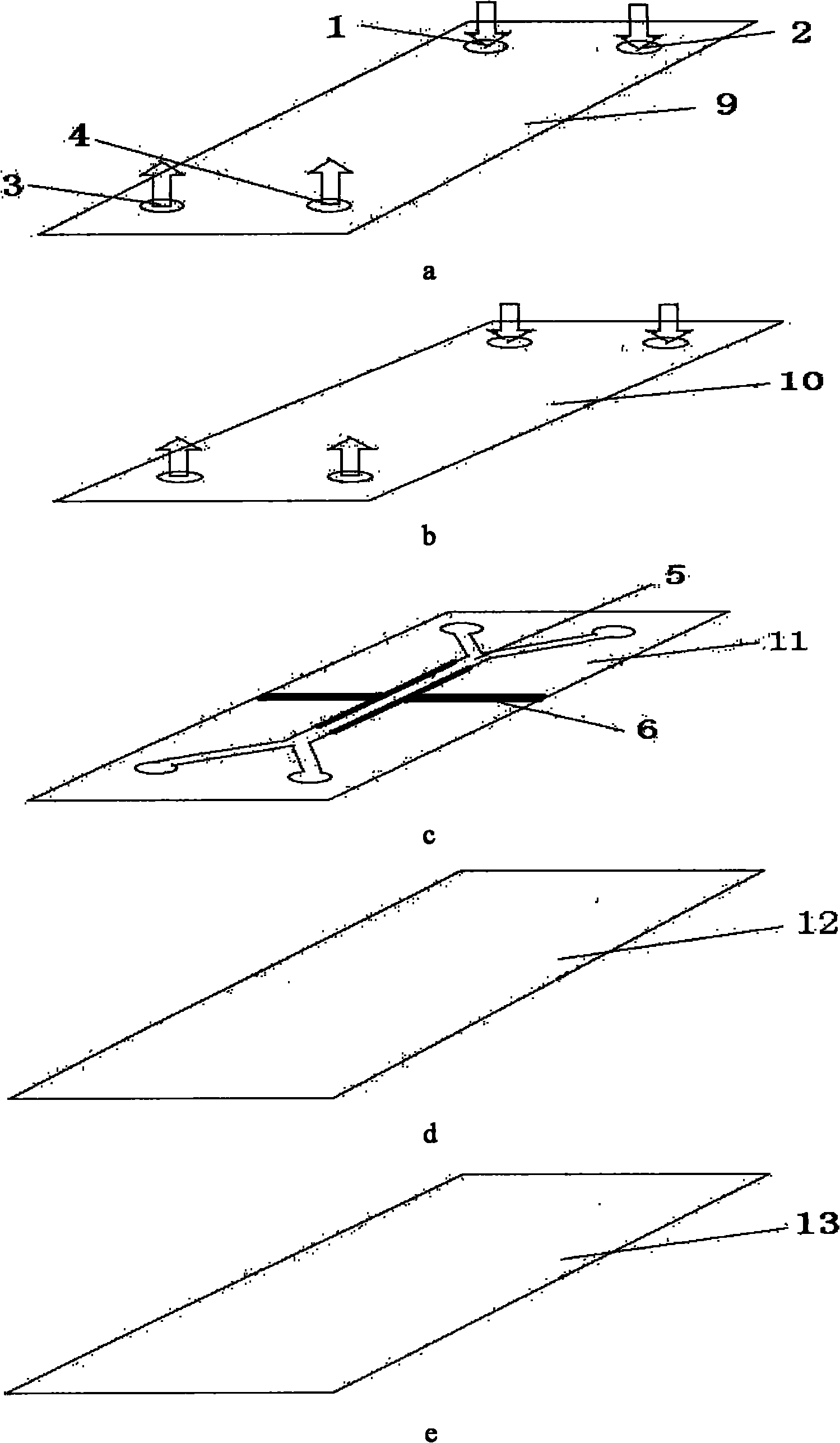

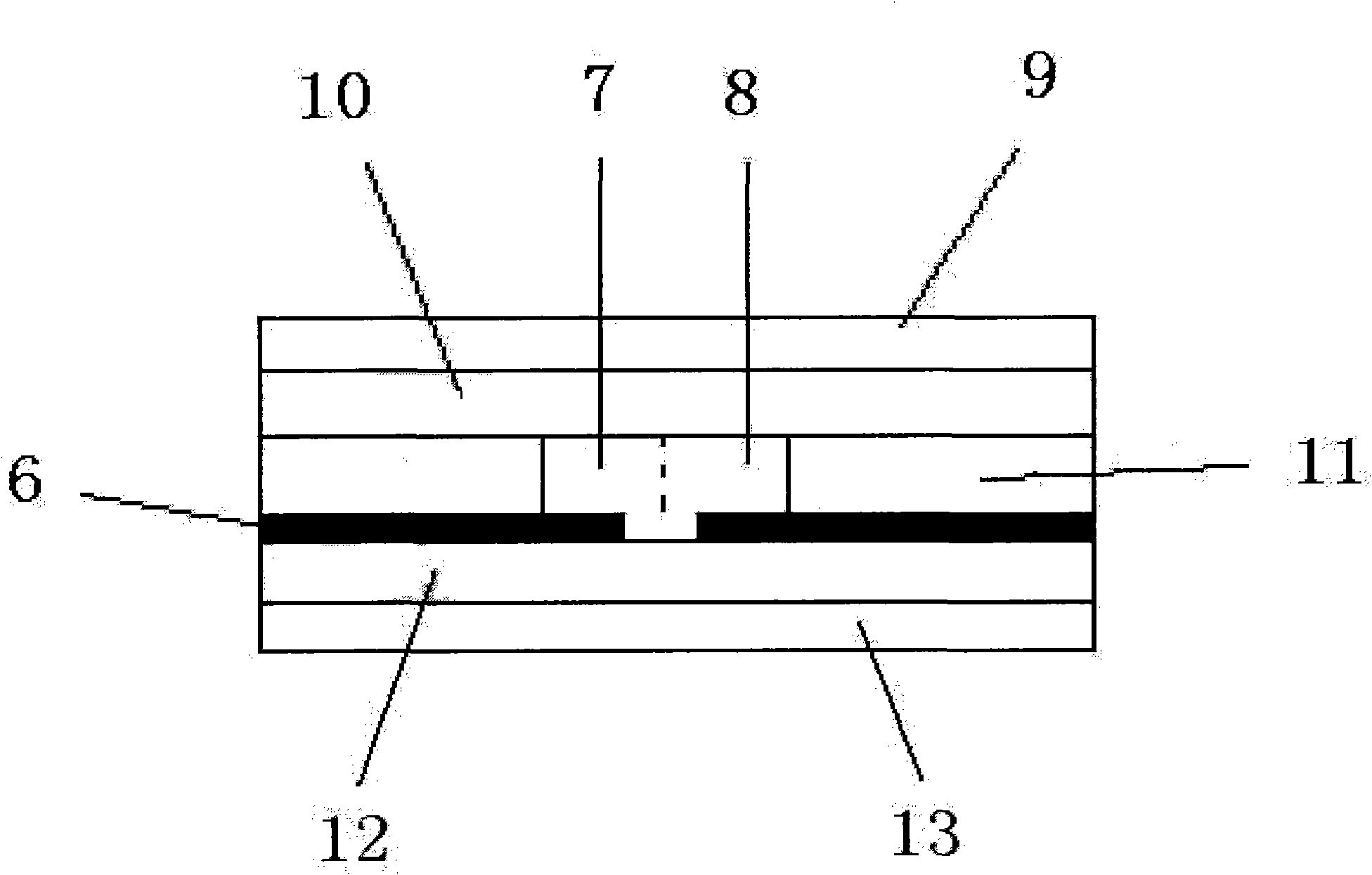

[0044] The material of the upper cover layer 9 of the single cell 14 is polycarbonate, and the specific size parameters are as follows: length × width × thickness = 50 × 30 × 2mm, the inlet of the positive electrolyte of the single cell 1, the inlet of the negative electrolyte of the single cell 2. The diameter of the electrolyte outlet 3 of the positive electrode of the single cell and the electrolyte outlet 4 of the negative electrode of the single cell is 4 mm.

[0045] The material of the single cell upper liner layer 10 of the single cell 14 is PDMS, and the specific size parameters are as follows: length × width × thickness = 50 × 30 × 5mm, and the four corners of the single cell upper liner layer 10 are provided with and single cell upper seals. On the cover layer 9, the single-cell positive electrolyte inlet 1, the single-cell negative electrolyte inlet 2, the single-cell positive electrolyte outlet 3 and the single-cell negative electrolyte outlet 4 are positioned on t...

Embodiment 2

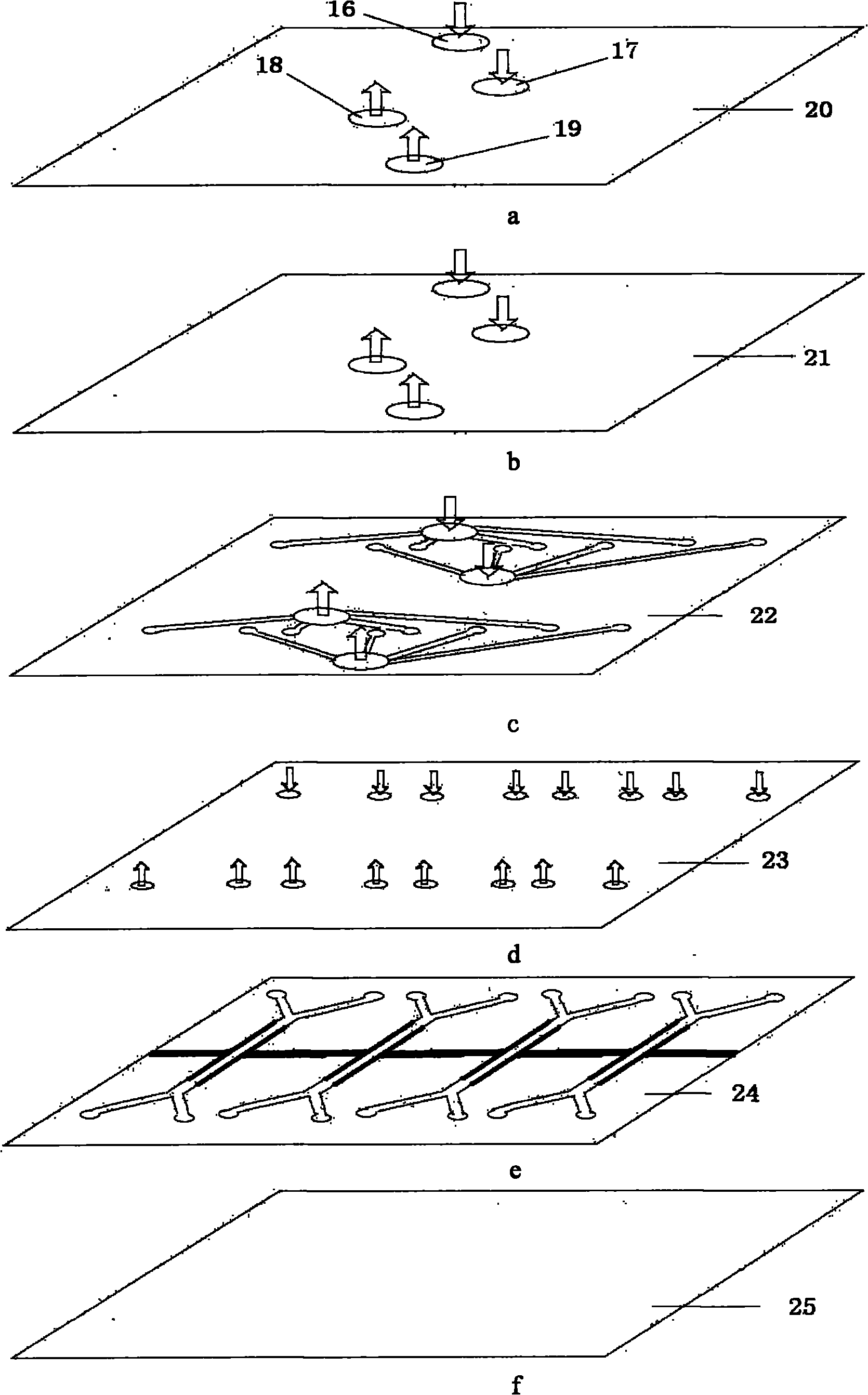

[0059] The material of the cover layer 20 on the battery stack of the battery stack 15 is polycarbonate, and the specific size parameters are as follows: length×width×thickness=200×100×2 mm, and the diameters of the four inlets and outlets are all 6 mm.

[0060] The material of the first backing layer 21 of the battery stack 15 is PDMS, and the specific size parameters are as follows: length×width×thickness=200×100×5mm, and the diameters of the four inlets and outlets are all 6mm.

[0061] The material of the first flow channel layer 22 of the battery stack 15 is PDMS, and the specific size parameters are as follows: length×width×thickness=200×100×0.5mm, the positive electrode of the first flow channel layer set in the middle of the first flow channel layer 22 of the battery stack The diameters of the electrolyte inlet, the negative electrolyte inlet of the first channel layer, the positive electrolyte outlet of the first channel layer and the negative electrolyte outlet of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com