Convection heating control method of electromagnetic oven and heating control device

A heating control device and convection heating technology, applied in the direction of induction heating control, induction heating device, induction heating, etc., can solve the problems of not raising, energy waste, and induction cooker can not be adjusted, and achieve the effect of promoting tumbling and even heating of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

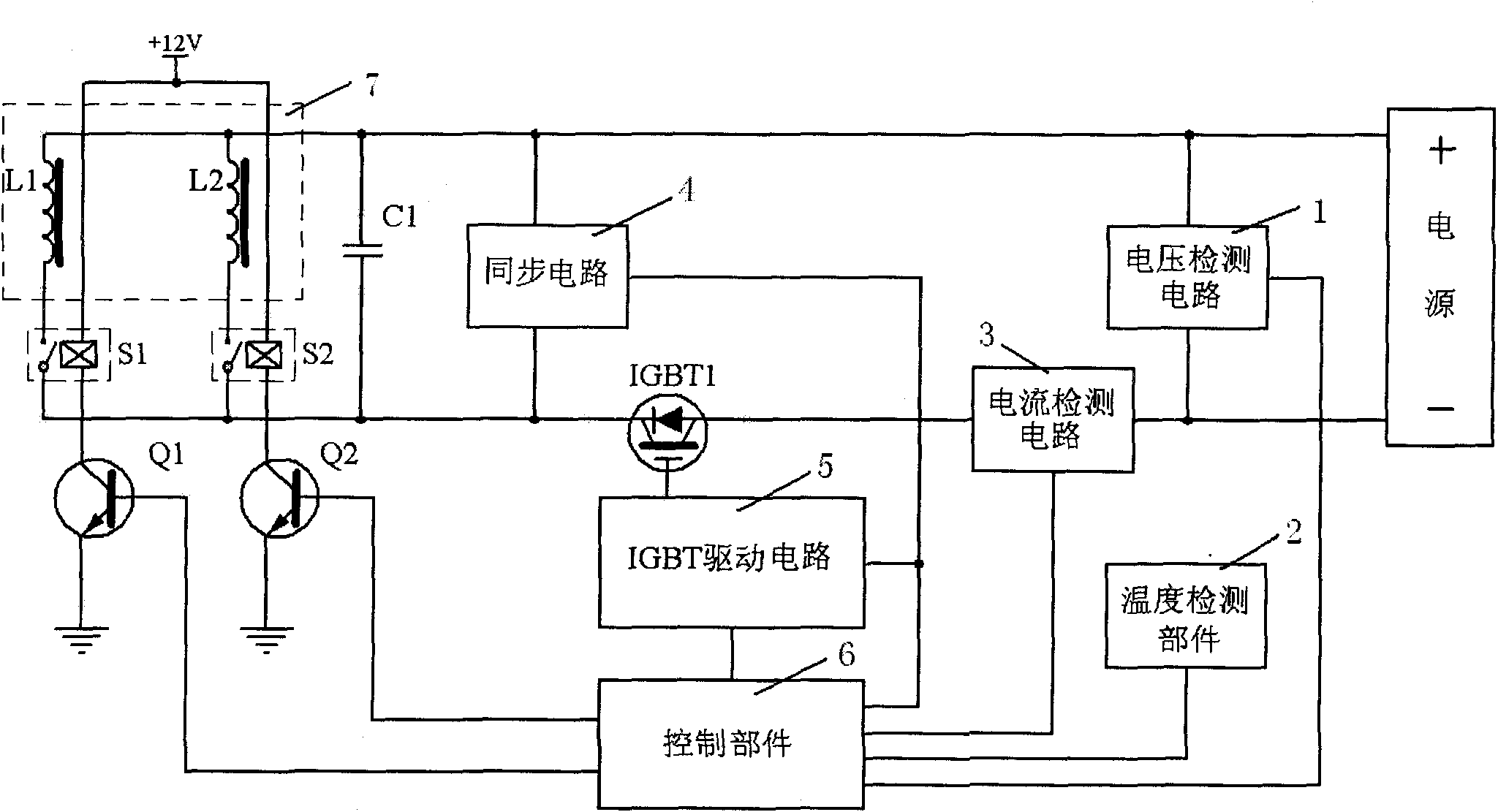

[0023] refer to figure 1 As shown, it is a schematic structural diagram of the heating control device according to the first embodiment of the present invention. The heating control device includes a control part 6 and a heating part 7. The heating part 7 includes at least two independently controllable electromagnetic coils L1 and L2. The control unit 6 includes a main controller, a timer and a preset memory, and the control unit 6 is electrically connected to the voltage detection circuit 1 , the temperature detection unit 2 , the current detection circuit 3 , the synchronization circuit 4 and the IGBT drive circuit 5 respectively. Wherein the voltage detection circuit 1 is connected with the power supply for detecting voltage conditions, and the voltage detection circuit 1 is also connected with the control unit 6 to input a voltage signal to the control unit 6; the temperature detection unit 2 is connected to the control unit 6 to the control unit 6 Input the real-time pot...

Embodiment 2

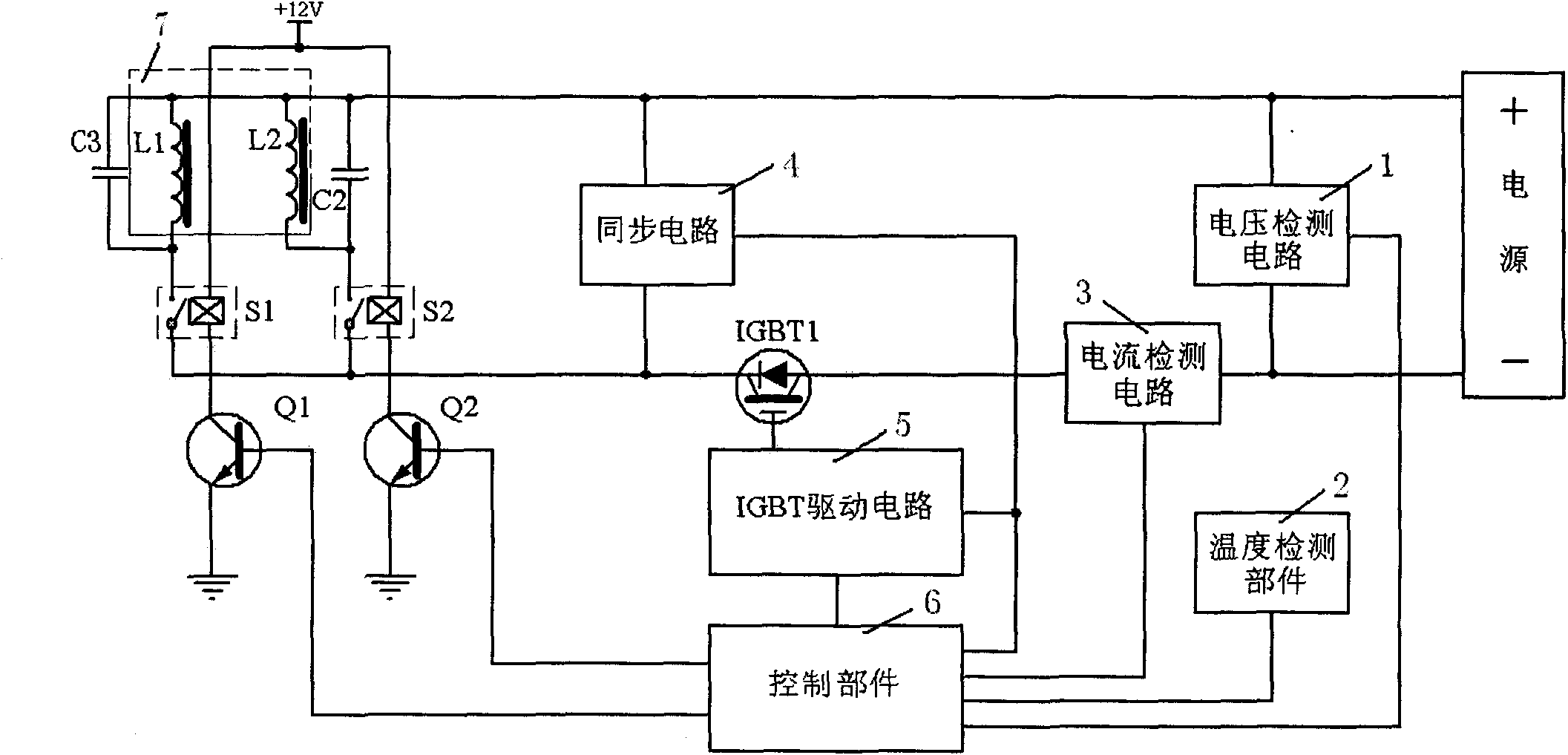

[0025] refer to figure 2 As shown, it is a schematic structural diagram of the heating control device of the second embodiment of the present invention. The difference between it and the first embodiment is that the filter capacitors C3 and C2 are connected in parallel at the two ends of the coils L1 and L2 respectively, so that the induction cooker can achieve a lower 300w low power or even lower power for continuous low power heating, effectively saving energy.

Embodiment 3

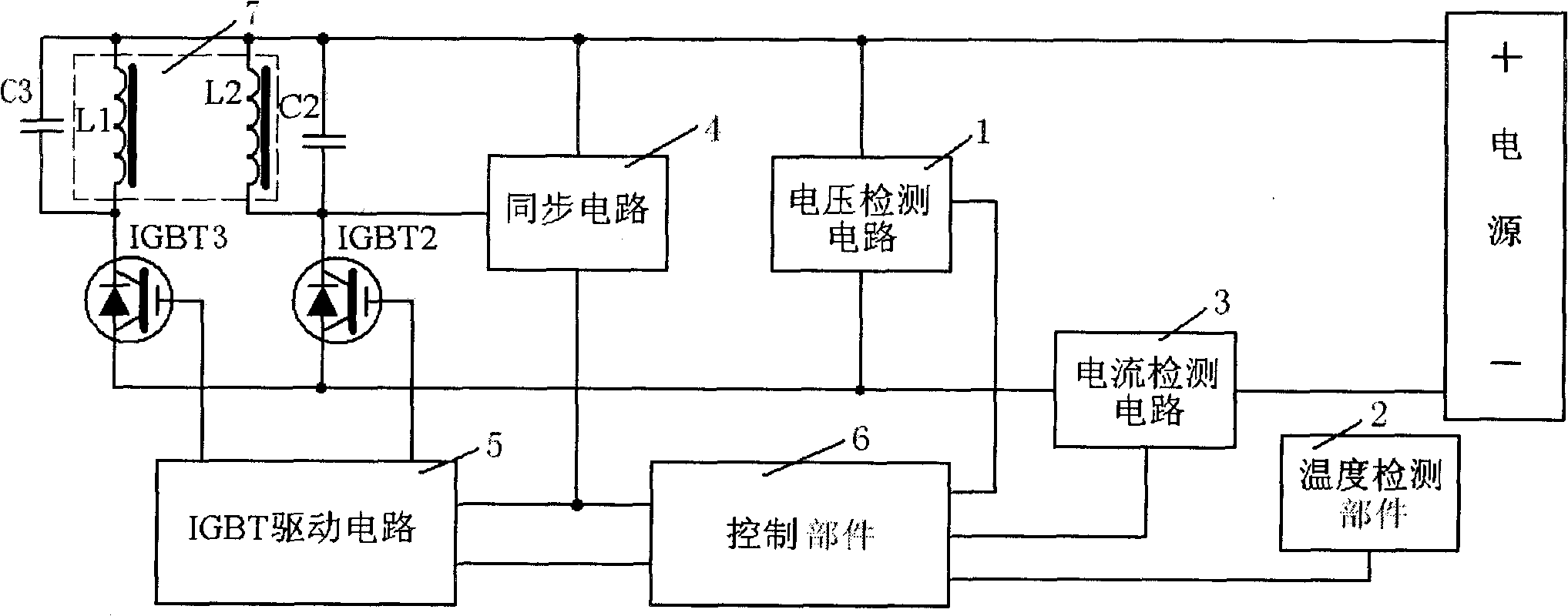

[0027] refer to image 3 As shown, it is a schematic structural diagram of the heating control device of the third embodiment of the present invention. The difference between it and the second embodiment is that the insulated gate bipolar power transistors IGBT3 and IGBT2 are used instead of the relays S1 and S2 to control the first coil L1 and the first coil L1 respectively. The heating operation of the second coil L2, and the drive transistors Q1 and Q2 are used to drive the on and off of S1 and S2 in the circuit, so they are discarded at the same time as the relays S1 and S2. In addition, since the heating operation of the power tube control coils L1 and L2 is directly set, the IGBT1 can be omitted at the same time to save cost. The technical solution of this embodiment uses a power tube instead of a relay to directly control the heating of the coil disk, which improves the reliability of the circuit and reduces the current consumption of the switching power supply.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com