Method of plasma treatment and plasma treatment apparatus

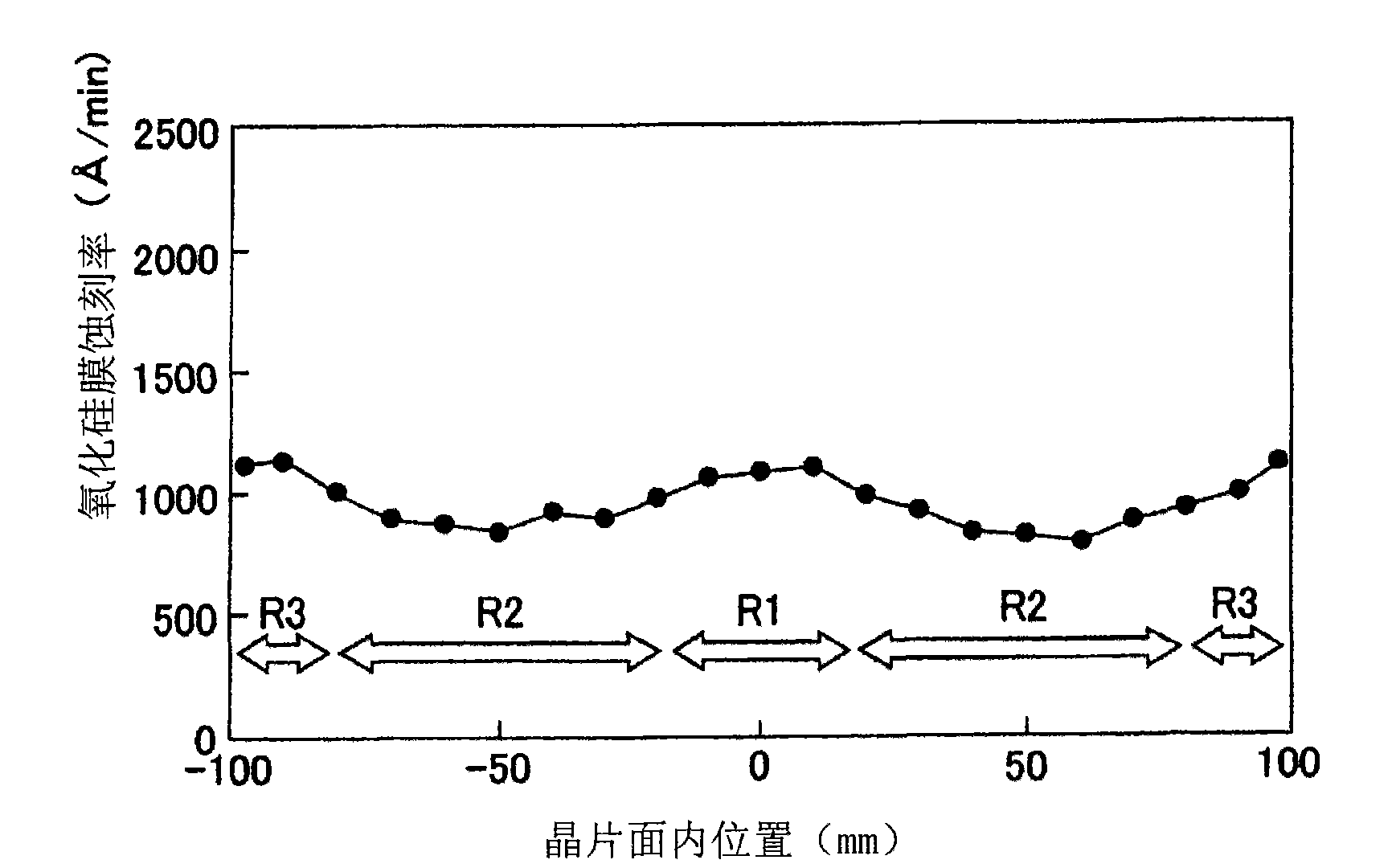

A plasma and processing method technology, applied in the fields of plasma processing and plasma processing equipment, can solve the problems of in-plane uniformity obstruction, uncontrollable ion density, etc., and achieve uniformity improvement, etching rate uniformity improvement, density Evenly distributed effect

Inactive Publication Date: 2010-08-18

TOKYO ELECTRON LTD

View PDF2 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, when an electronegative gas such as the above-mentioned fluorocarbon-based gas is used as the processing gas, it is known that the ion density in the plasma tends to be partially biased regardless of where it is introduced from within the processing chamber. Tends to be an obstacle to the goal of further improving in-plane uniformity

That is, in the case of using an electronegative gas as the processing gas, the ion density in the plasma of the processing gas cannot be controlled only by changing the flow rate and concentration from different parts of the processing chamber to introduce the processing gas. There is a limit to the aspect of improving in-plane uniformity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

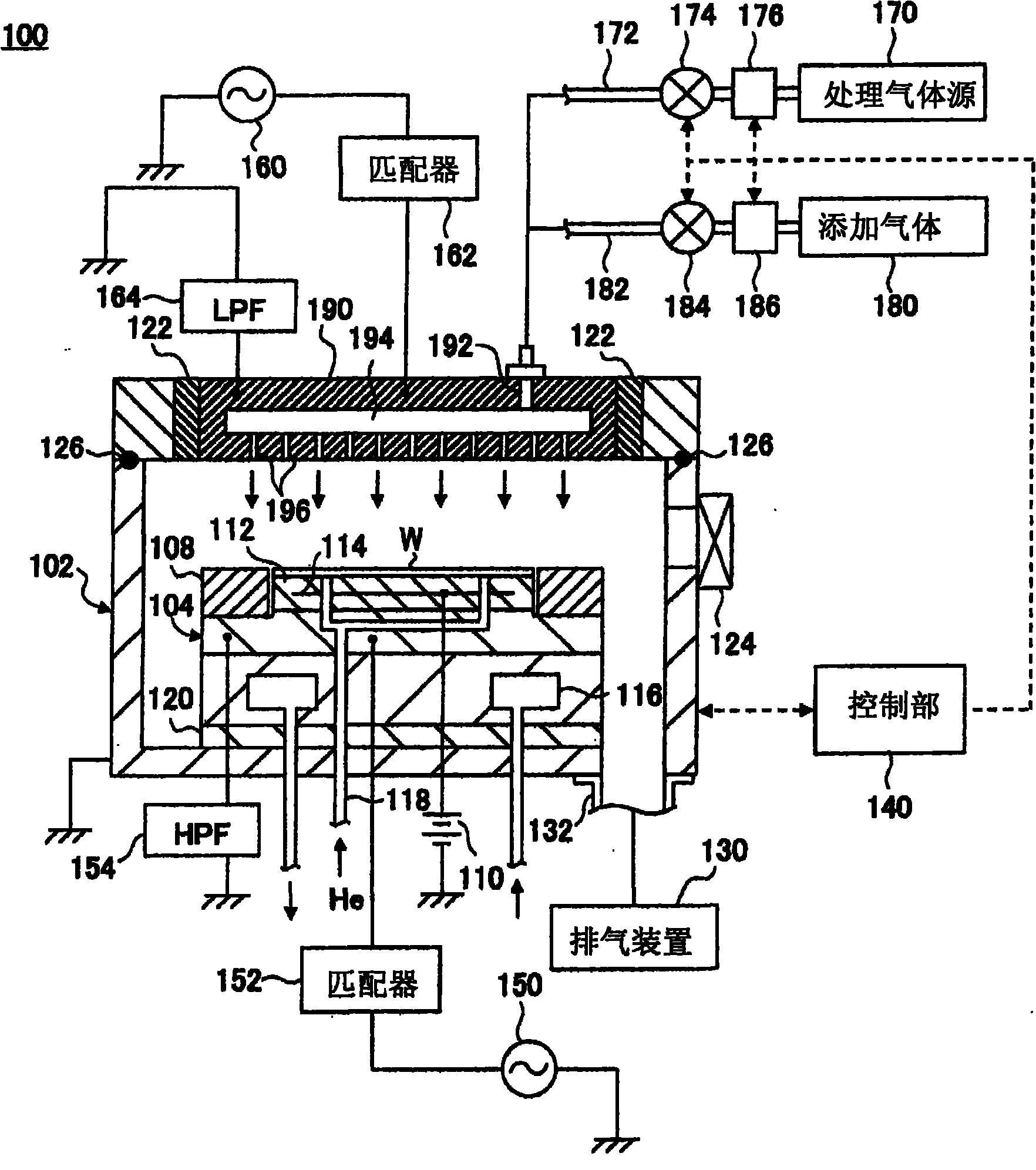

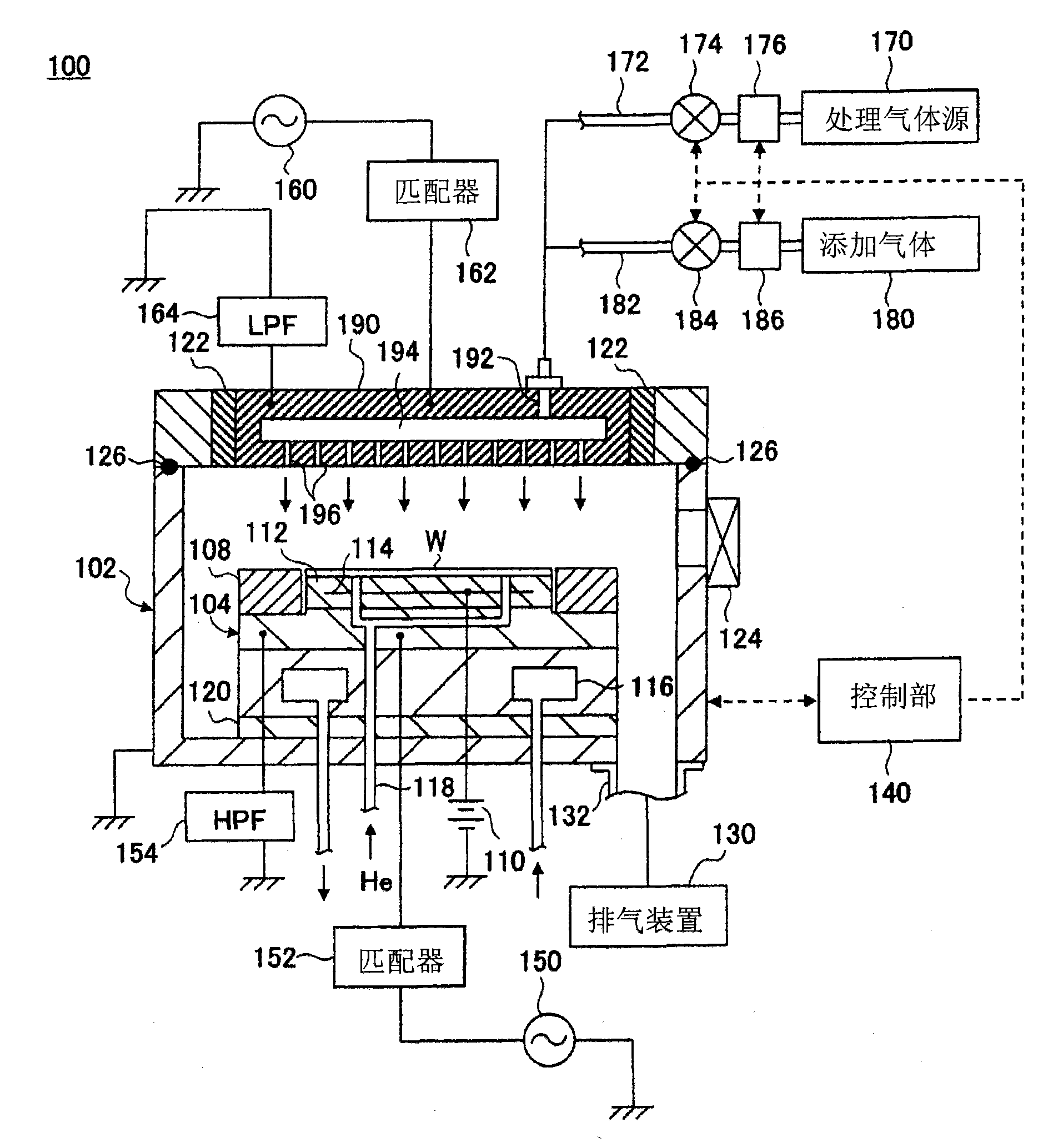

In the plasma treatment by an electrically negative gas, the in-plane uniformity of plasma treatment is enhanced over the prior art by controlling the ion density in the plasma. Not only is a treating gas being an electrically negative gas introduced from a treating gas source (170) into a treatment chamber (102) but also an electrically negative gas greater in electron attachment coefficient than the treating gas is introduced as an addition gas from an addition gas source (180) to thereby form a plasma. In the plasma formation, the ion density in the plasma is controlled by regulating the flow rate of the addition gas relative to the treating gas.

Description

Plasma treatment method and plasma treatment apparatus technical field The present invention relates to a plasma processing method and a plasma processing apparatus for performing predetermined plasma processing on a substrate to be processed. Background technique In general, in the manufacturing process of semiconductor devices, film formation, etching, heat treatment, modification, crystallization, etc. Various processes, thereby forming a desired semiconductor integrated circuit. Among the above-mentioned various treatments, for example, in the etching treatment process, a plasma etching treatment method (for example, refer to Patent Document 1) is often used, that is, a predetermined etching gas is used as a processing gas from a shower head disposed on the upper part of the processing chamber. The etching gas is introduced into the processing chamber, and the etching gas is converted into plasma by high-frequency power or the like, and the plasma is applied to the s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L21/3065

CPCH01J37/32091H01J37/32449H01L21/31116H01J37/3244

Inventor 川上雅人永关澄江伊藤融

Owner TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com