Method for preparing organophosphorus insecticide nano silica gel surface molecular imprinted polymer

A technology of nano-silica gel and molecular imprinting, applied in alkali metal compounds, chemical instruments and methods, inorganic chemistry, etc., to achieve good molecular recognition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Mix 50mL of absolute ethanol and 9mL of concentrated ammonia water to obtain solution A; then mix 5mL of TEOS and 30mL of absolute ethanol to obtain solution B; continuously drop solution B into a high-speed magnetic stirring tank at a rate of 15d / s at room temperature In solution A, the rotation speed was 700 rpm, and the stirring was continued for 24 hours after the dropwise addition; repeated ultrasonic washing with absolute ethanol until neutral, centrifuged, and vacuum drying at 60°C until constant weight. Obtain silica gel pellets of about 400nm.

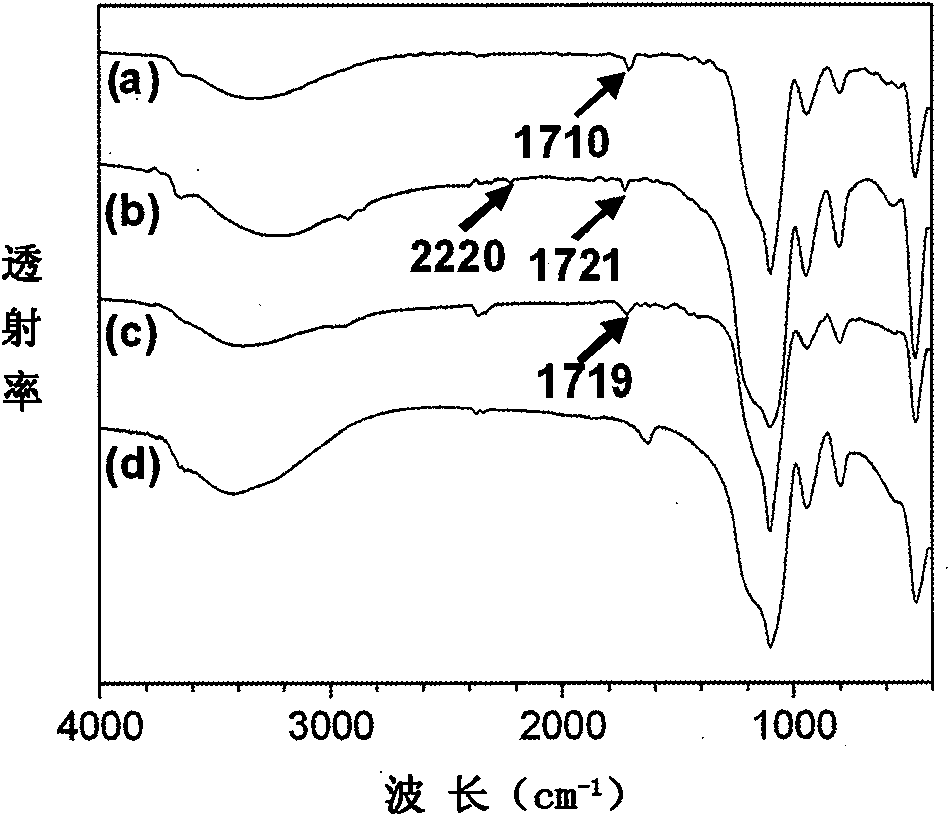

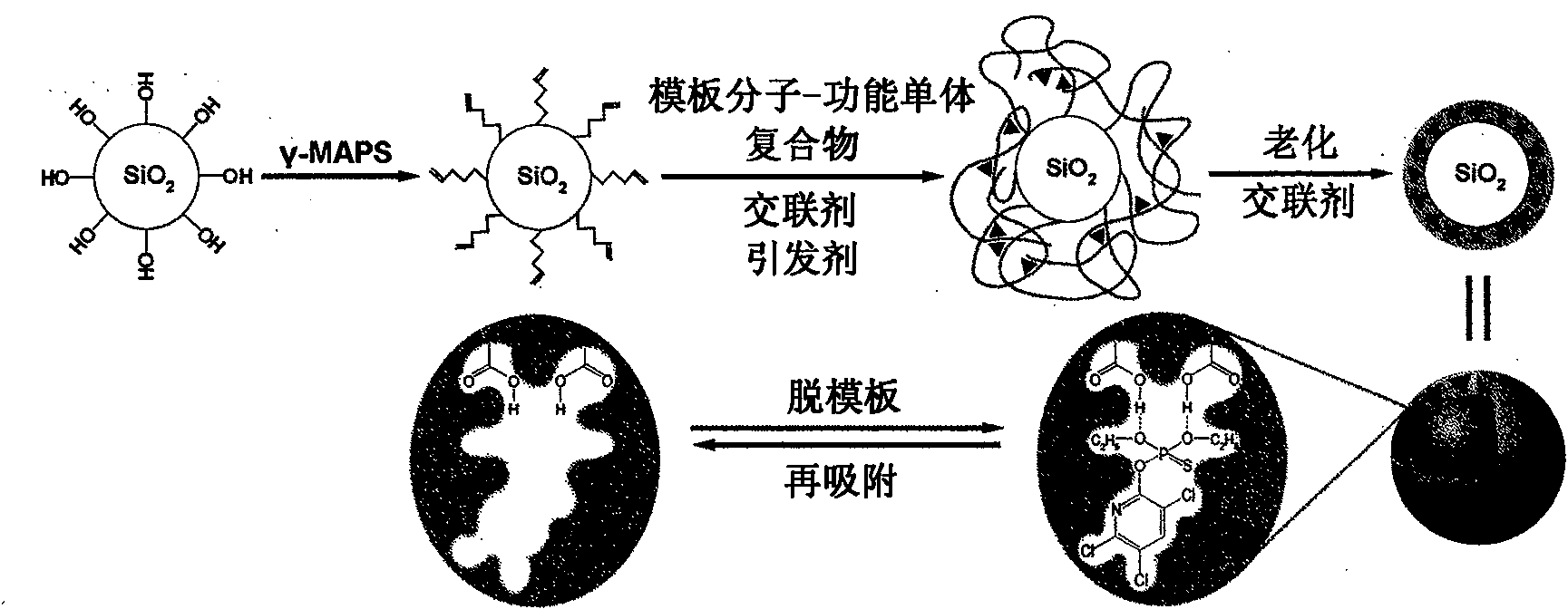

[0025] The prepared SiO 2 Microspheres were placed in 50mL (10mol L -1 ) hydrochloric acid solution, acidified for 24 hours, washed repeatedly with ultrapure water to neutrality, centrifuged, placed in a vacuum oven, and dried to constant weight at 60°C; weighed the acidified SiO 2 Ultrasonic dispersion of 0.5 g of microspheres in a certain amount of toluene solution, adding 10 mL of γ-MPTS so that the volume concentr...

Embodiment 2

[0029] Mix 50mL of absolute ethanol and 9mL of concentrated ammonia water to obtain solution A; then mix 5mL of TEOS and 30mL of absolute ethanol to obtain solution B; continuously drop solution B into a high-speed magnetic stirring tank at a rate of 15d / s at room temperature In solution A, the rotation speed was 700 rpm, and the stirring was continued for 24 hours after the dropwise addition; repeated ultrasonic washing with absolute ethanol until neutral, centrifuged, and vacuum drying at 60°C until constant weight. Obtain silica gel pellets of about 400nm.

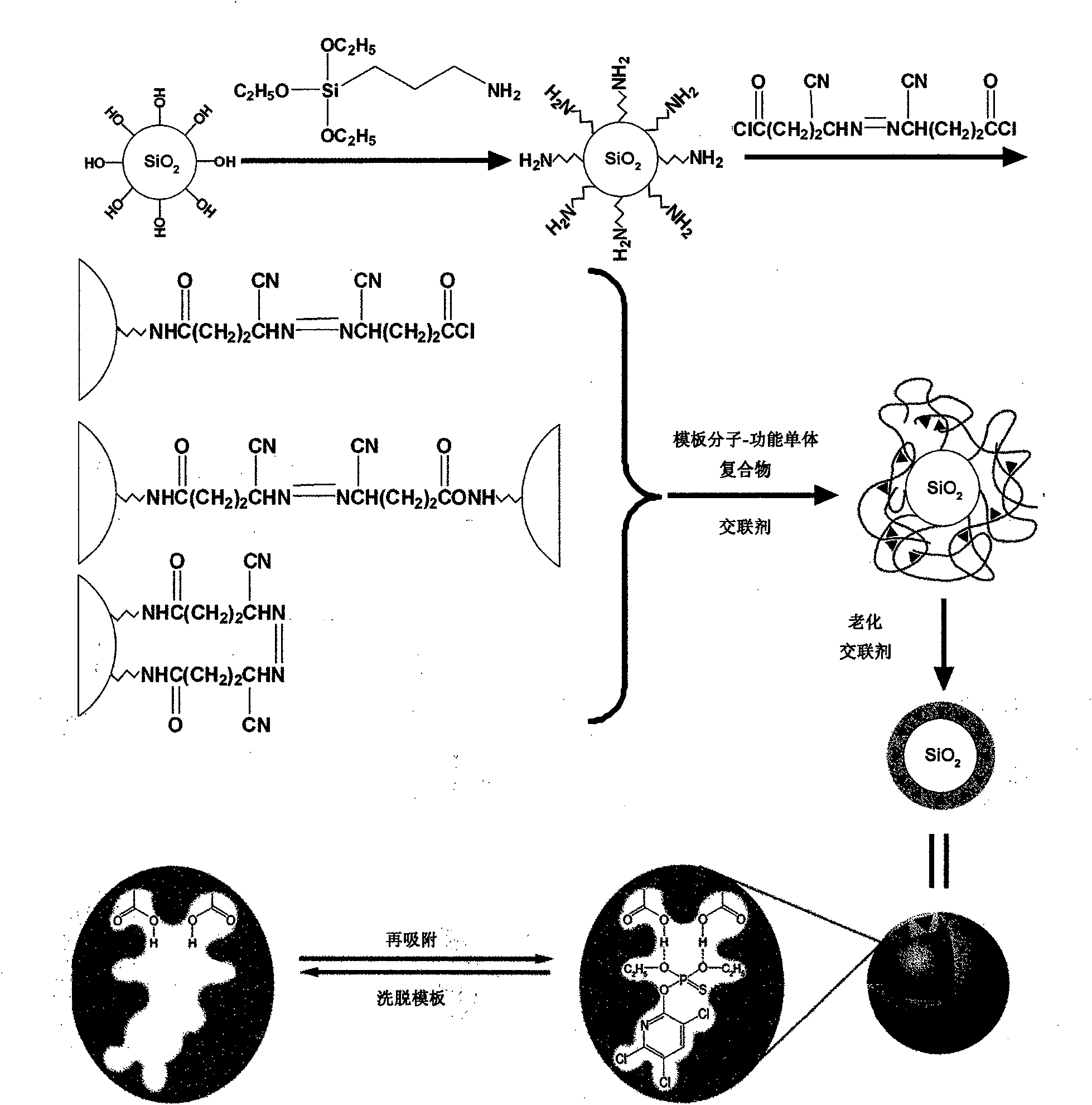

[0030] The prepared SiO 2 Microspheres were placed in 50mL (10mol L -1 ) hydrochloric acid solution, acidified for 24 hours, washed repeatedly with ultrapure water to neutrality, centrifuged, placed in a vacuum oven, and dried to constant weight at 60°C; then weighed the acidified SiO 2 Ultrasonic disperse 0.5g of microspheres in a certain amount of toluene solution, add 10mL of γ-APTS to make the volume concentration...

Embodiment 3

[0035] Mix 50mL of absolute ethanol and 9mL of concentrated ammonia water to obtain solution A; then mix 5mL of TEOS and 30mL of absolute ethanol to obtain solution B; continuously drop solution B into a high-speed magnetic stirring tank at a rate of 15d / s at room temperature In solution A, the rotation speed was 700 rpm, and the stirring was continued for 24 hours after the dropwise addition; repeated ultrasonic washing with absolute ethanol until neutral, centrifuged, and vacuum drying at 60°C until constant weight. Obtain silica gel pellets of about 400nm.

[0036] The prepared SiO 2 Microspheres were placed in 50mL (10mol L -1 ) hydrochloric acid solution, acidified for 24 hours, washed repeatedly with ultrapure water to neutrality, centrifuged, placed in a vacuum oven, and dried to constant weight at 60°C; then weighed the acidified SiO 2 Ultrasonic disperse 0.5g of microspheres in a certain amount of toluene solution, add 10mL of γ-APTS to make the volume concentration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com