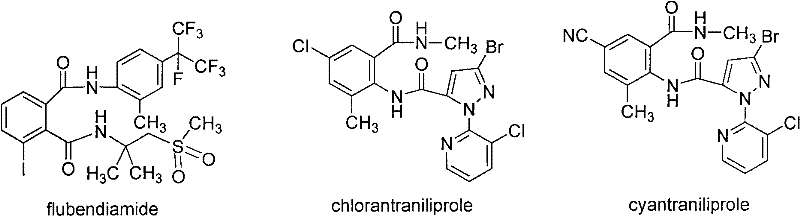

Preparation method and application of diamide insecticide molecular imprinted polymer

A molecular imprinting and pesticide technology, which is applied in the field of preparation of diamide pesticide molecularly imprinted polymers, can solve problems such as difficulty in meeting requirements, and achieve the effects of low preparation cost, strong operability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

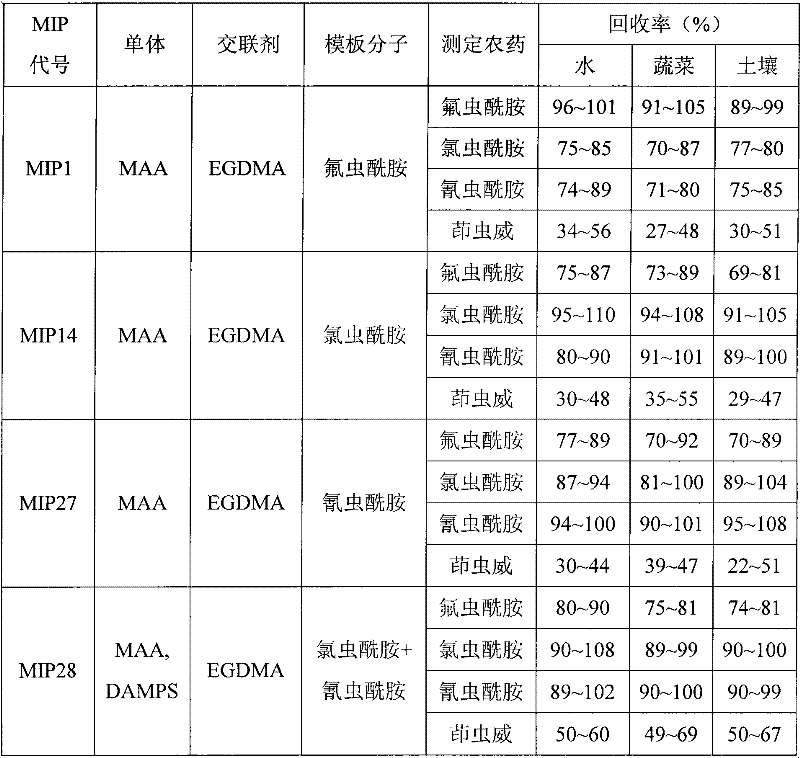

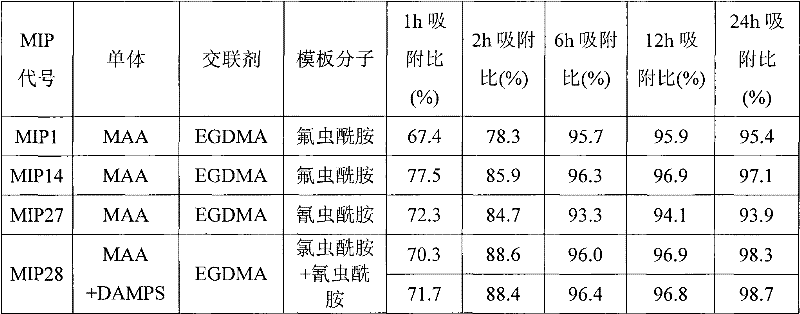

[0020] Example 1: Preparation of Flubendiamide Molecularly Imprinted Polymer MIP1

[0021] Weigh 0.0451g template molecule flubendiamide, 0.5026g reaction monomer methacrylic acid (MAA), 4.9041g crosslinking agent ethylene glycol dimethacrylate (EGDMA), 0.09209g initiator azobisisonitrile, 10mL Porogen chloroform, mixed evenly, put into a 20mL ampoule, deoxygenated by nitrogen for 10 minutes, and sealed. React the airtight ampoule in an oven at 70°C for 48 hours (or react for 12 to 36 hours under the irradiation of a 125W or 150W high-pressure mercury lamp) to obtain a block-shaped molecularly imprinted polymer of flubendiamide. The single polymer is taken out, ground and pulverized, dried and passed through a 100-200 mesh sieve to obtain flabendil molecularly imprinted polymer particles. Use methanol-acetic acid mixed solution (9:1, V / V) to repeatedly ultrasonically clean the template molecules in the prepared polymer particles until no template molecules can be detected at ...

Embodiment 2~13

[0022] Examples 2-13: Preparation of flubendiamide molecularly imprinted polymers MIP2-MIP13 in a similar manner to Example 1

[0023]

[0024] implement

Embodiment 14

[0025] Example 14: Preparation of chlorantraniliprole molecularly imprinted polymer MIP14

[0026] Weigh 0.0401g template molecule chlorantraniliprole, 0.4538g reaction monomer methacrylic acid (MAA), 4.1154g crosslinking agent ethylene glycol dimethacrylate (EGDMA), 0.0901g initiator azobisisonitrile, 10mL Porogen chloroform, mixed evenly, put into a 20mL ampoule, deoxygenated by nitrogen for 10 minutes, and sealed. React the airtight ampoule in an oven at 70°C for 48 hours (or react for 12-36 hours under the irradiation of a 125W or 150W high-pressure mercury lamp) to obtain a block-shaped molecularly imprinted polymer of chlorantraniliprole. The single polymer is taken out, ground and pulverized, dried and passed through a 100-200 mesh sieve to obtain chlorantraniliprole molecularly imprinted polymer particles. Use methanol-acetic acid mixed solution (9:1, V / V) to repeatedly ultrasonically clean the template molecules in the prepared polymer particles until no template mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com