Magnesium base hydride composite system for hydrolysis hydrogen production and preparation method and application thereof

A technology for magnesium-based hydride and hydrogen production by hydrolysis, which is applied in the field of a magnesium-based hydride composite system for hydrolysis and hydrogen production and its preparation field, and can solve the problems of poor hydrolysis reaction kinetic performance, harsh hydride production conditions, and low effective hydrogen production. and other problems, to achieve the effect of simple and easy hydrogen production facilities, abundant reserves of magnesium resources, and high hydrolysis activity

Inactive Publication Date: 2010-08-25

NANJING UNIV OF TECH

View PDF1 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the kinetics of the hydrolysis reaction of magnesium-based hydrides is poor, and the effective hydrogen production is low.

At the same time, the preparation conditions of the hydride are harsh. The traditional preparation method needs to react with hydrogen at 300-400 ° C and a pressure of 40 MPa, and the preparation cost is relatively high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

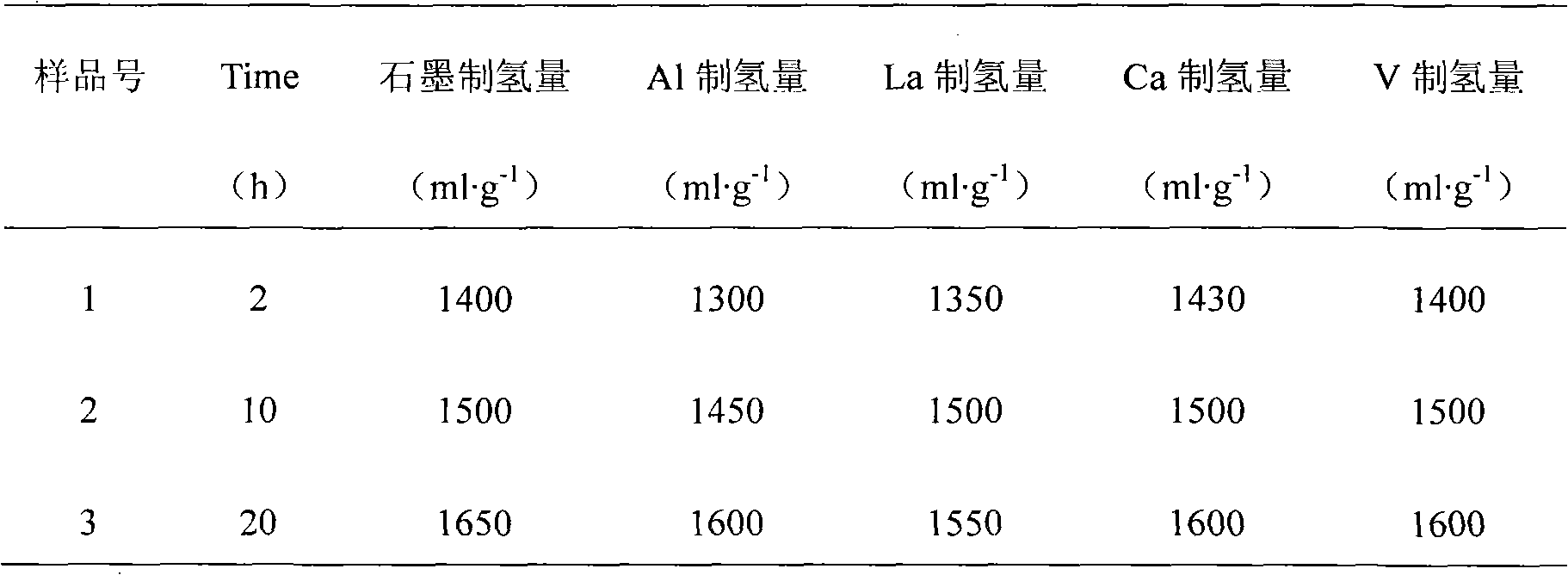

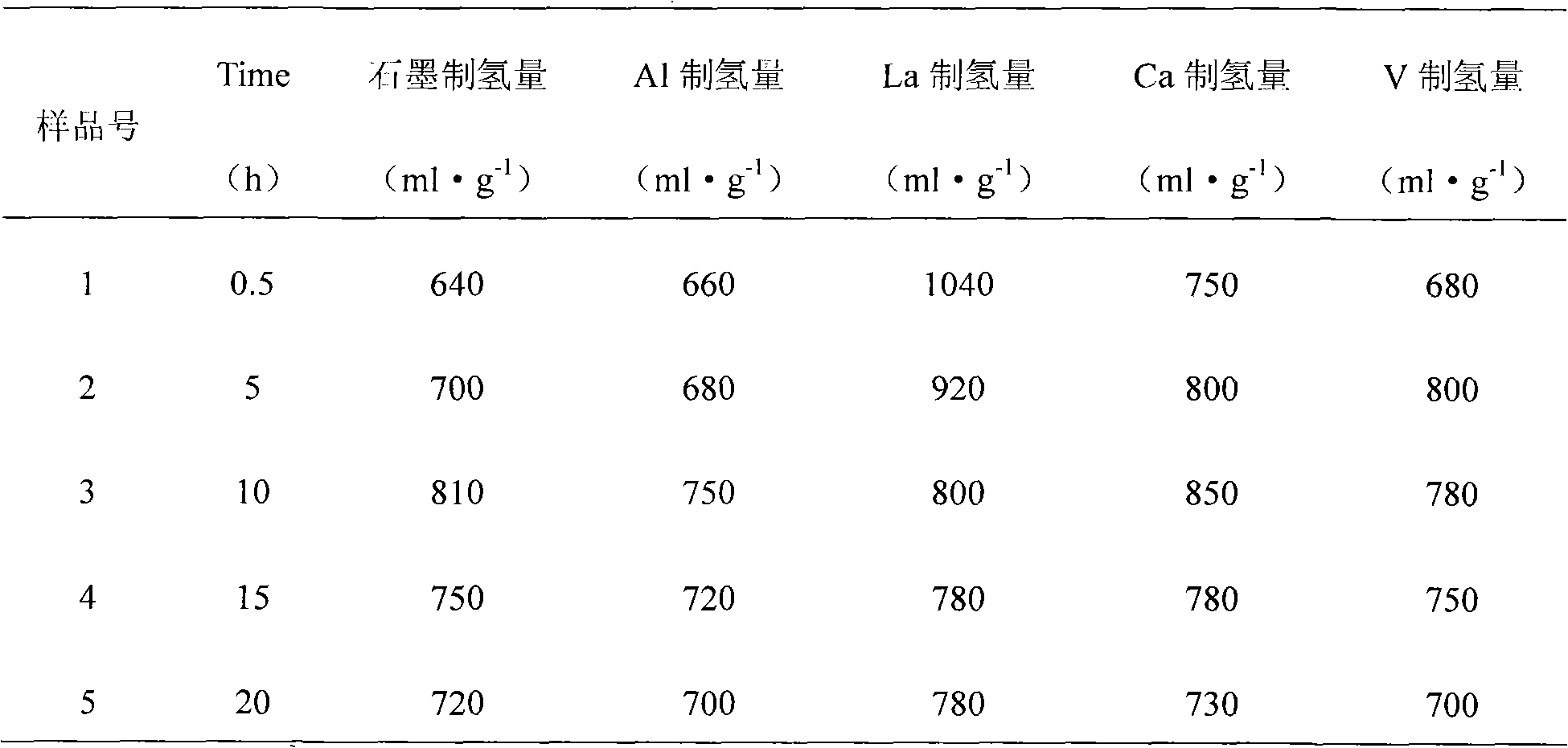

The invention discloses a magnesium base hydride composite system for hydrolysis hydrogen production and a preparation method and application thereof. The composite system is prepared by a method comprising the following steps of: taking magnesium powder and nickel powder in a mole ratio of 30:1-49:1; performing hydrogenation combustion synthesis under the action of a catalyst and an organic dispersant which account for 3 to 10 percent of the total weight of the mixture of the magnesium powder and the nickel powder; and performing strong mechanical ball milling. The magnesium hydride in the prepared magnesium base hydride composite system for the hydrolysis hydrogen production accounts for 95 to 98 percent of the weight of hydride, and the magnesium nickel hydride accounts for 2 to 5 percent; the catalyst is one of graphite, B, Al, La, Ca, V, Ce and Nb; the magnesium hydride is MgH2; and the magnesium nickel hydride is a mixture of Mg2NiH4 and Mg2NiH0.3 in any ratio. The theoretical hydrogen production amount of the composite system is up to 1,600 ml / g, and a preparation process of the magnesium base hydride composite system is time-saving, energy-saving and simple and is easy for industrial production.

Description

Technical field: The invention relates to the technical field of energy chemistry and chemical power supply products, in particular to a magnesium-based hydride composite system for hydrogen production by hydrolysis, a preparation method thereof, and an application for hydrogen production. Background technique: With the development of society, people's demand for energy is increasing, traditional fossil energy is becoming exhausted, CO 2 The emissions are causing the greenhouse effect to become more and more serious. Under such circumstances, people urgently need to develop new green alternative energy sources, and hydrogen energy is one of the most promising forms of energy. Hydrogen is a high-energy-density, clean new energy with a wide range of sources, and it has no toxic side effects on the human body. In recent years, fuel cells have developed rapidly, especially proton exchange membrane fuel cells, which are expected to become an important power generation method in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B6/04C01B6/02C01B3/04

CPCY02E60/364Y02E60/36

Inventor 李李泉朱云峰沈品

Owner NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com