Production method of doped ferrous oxalate

A production method and technology for ferrous oxalate, applied in the field of production of doped ferrous oxalate, can solve the problems of not much improvement of particles, material particle size, uneven distribution, electrical conductivity and other problems

Inactive Publication Date: 2010-08-25

朱辰

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention aims at the defects of current existing methods for preparing doped LFP materials, and aims to provide a new doping method for preparing LFP positive electrode materials to improve the electrical conductivity inside LFP particles. The technical problem to be solved is to carry out the doping, and make the precursor of LFP

The traditional method uses mechanical mixing, which has the inhomogeneity of the size and distribution of material particles, and more importantly, it only solves the problem of electrical conductivity outside most of the particles of the finished product, and does not improve the interior of the particles much.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

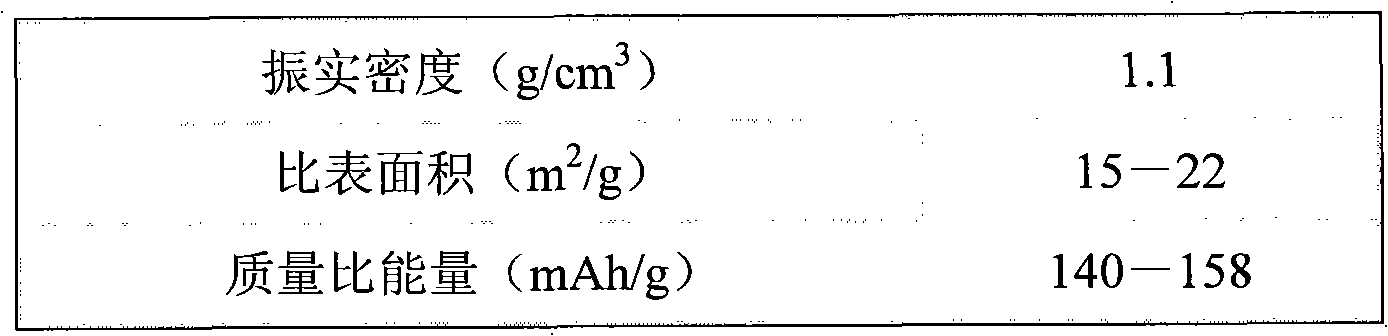

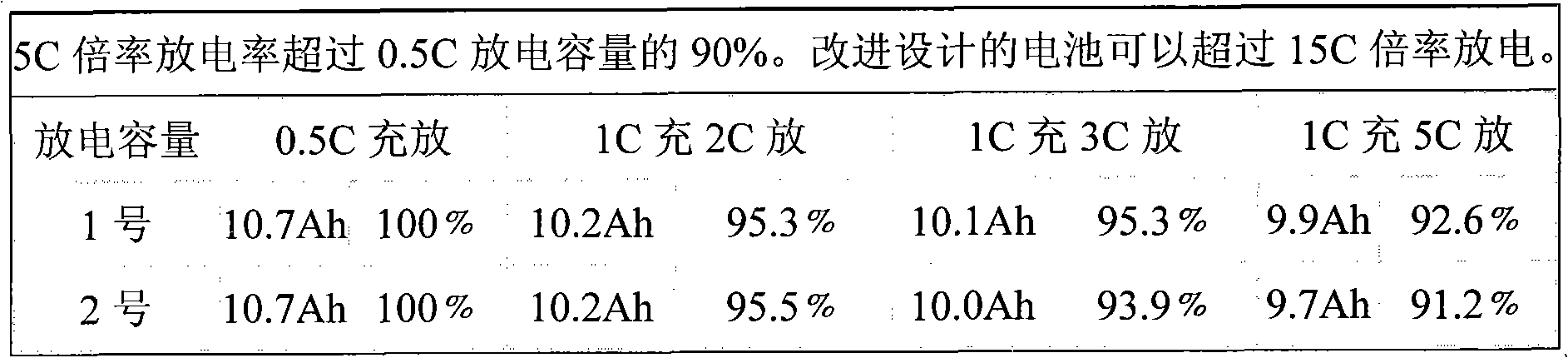

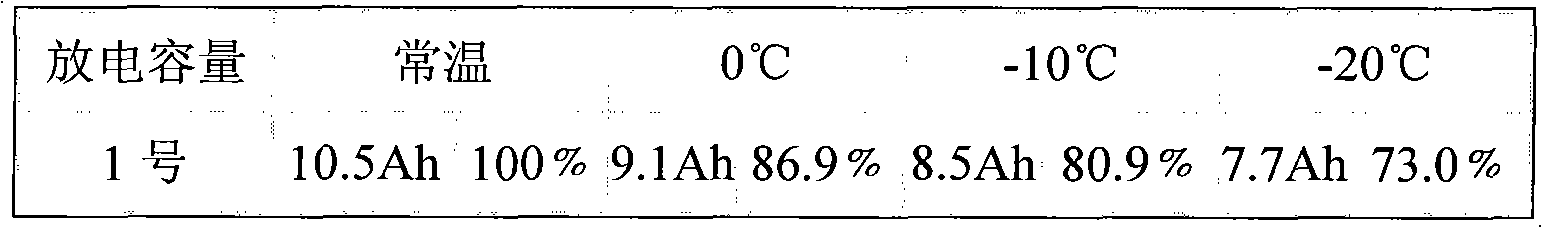

The invention relates to a production method of doped ferrous oxalate, which takes ferrous sulfate and oxalic acid as raw materials, and comprises the steps of purifying, synthesizing, separating, washing and drying. The production method is characterized in that after purification, when the ferrous sulfate and the oxalic acid are synthesized in water solution, ammonium oxalate and metal salt are added into the solution at 60-140 DEG C and stirred for reaction for 5-40min, wherein the ammonium oxalate has the mass percent concentration of 0.2-1% in reaction liquid, and the adding quantity of the metal salt is 0.1-4% of the mass of the ferrous sulfate. The method leads 2500mu g / g of impurity ions to be doped into ferrous oxalate crystal, thus improving the electric conduction performance of LFP. A lithium battery processed by LFP cathode material prepared by the ferrous oxalate has good charging and discharging characteristics under different multiplying powers, and circulating performance at high and low temperature.

Description

1. Technical field The invention relates to a method for preparing raw materials required for power lithium batteries, in particular to a method for preparing raw materials required for positive electrode materials of lithium iron phosphate batteries, in particular to a method for producing ferrous oxalate doped. 2. Background technology Ferrous oxalate is lithium iron phosphate lithium iron phosphate (LiFePO 4 , one of the main raw materials of LFP). LFP material itself has poor conductivity, and the low diffusion coefficient of lithium-ion batteries has always been the main reason hindering its popularization and application, prompting domestic and foreign scholars to carry out improvement research on improving the conductivity of LFP. Because the performance of LFP is related to the synthesis method, and the traditional high-temperature solid-phase method has high energy consumption, long cycle, poor controllability, serious agglomeration phenomenon, resulting in unstabl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C55/07C07C51/41

Inventor 朱辰

Owner 朱辰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com