Polyolefin functional master batch, preparation method thereof and use thereof

A functionalized, polyolefin technology, applied in the direction of conjugated synthetic polymer man-made filaments, etc., can solve the problems of spinning, film drawing processing difficulties, inability to kill bacteria quickly, toxicity of leachables, etc., to overcome easy migration and durability. Poor performance, improved antimicrobial properties, and significant inhibitory effects

Active Publication Date: 2010-08-25

SHANGHAI FUYUAN PLASTICS SCI CO LTD

View PDF12 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Natural antibacterial agents are restricted by raw materials and processing conditions, and it is not yet possible to achieve large-scale marketization

Organic antibacterial agents have the advantages of fast sterilization speed and wide antibacterial range, but there are also problems such as poor heat resistance, easy oozing, toxicity of leachate, and short service life of washing resistance, so their use has great limitations.

Inorganic antibacterial agents are mainly silver antibacterial agents, which are characterized by safety, heat resistance, and durability. They are currently widely used in fibers, plastics, and building materials. The disadvantage is that they are relatively expensive. And antibacterial slow effect, can not kill bacteria quickly like organic antibacterial agents; at the same time, due to the active chemical properties of silver, it is easy to oxidize and become brown silver oxide, thereby reducing the antibacterial effect and affecting the appearance of products; In addition, inorganic Antibacterial powder has poor compatibility with polymer materials, and is easy to agglomerate in the matrix resin, which will bring great difficulties to the processing of materials such as spinning and film drawing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Login to View More

Abstract

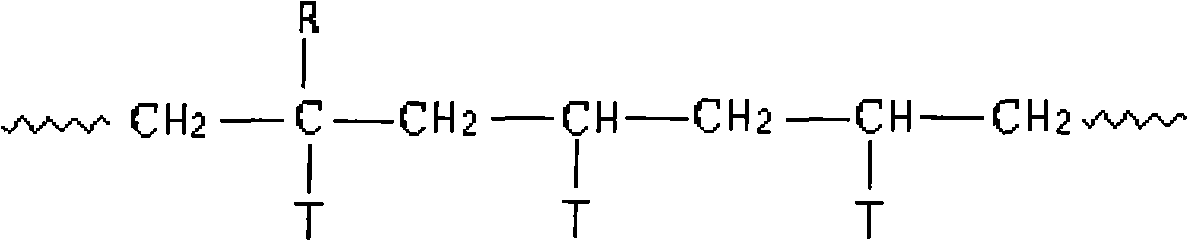

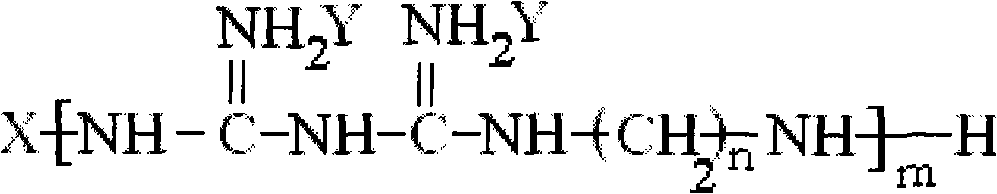

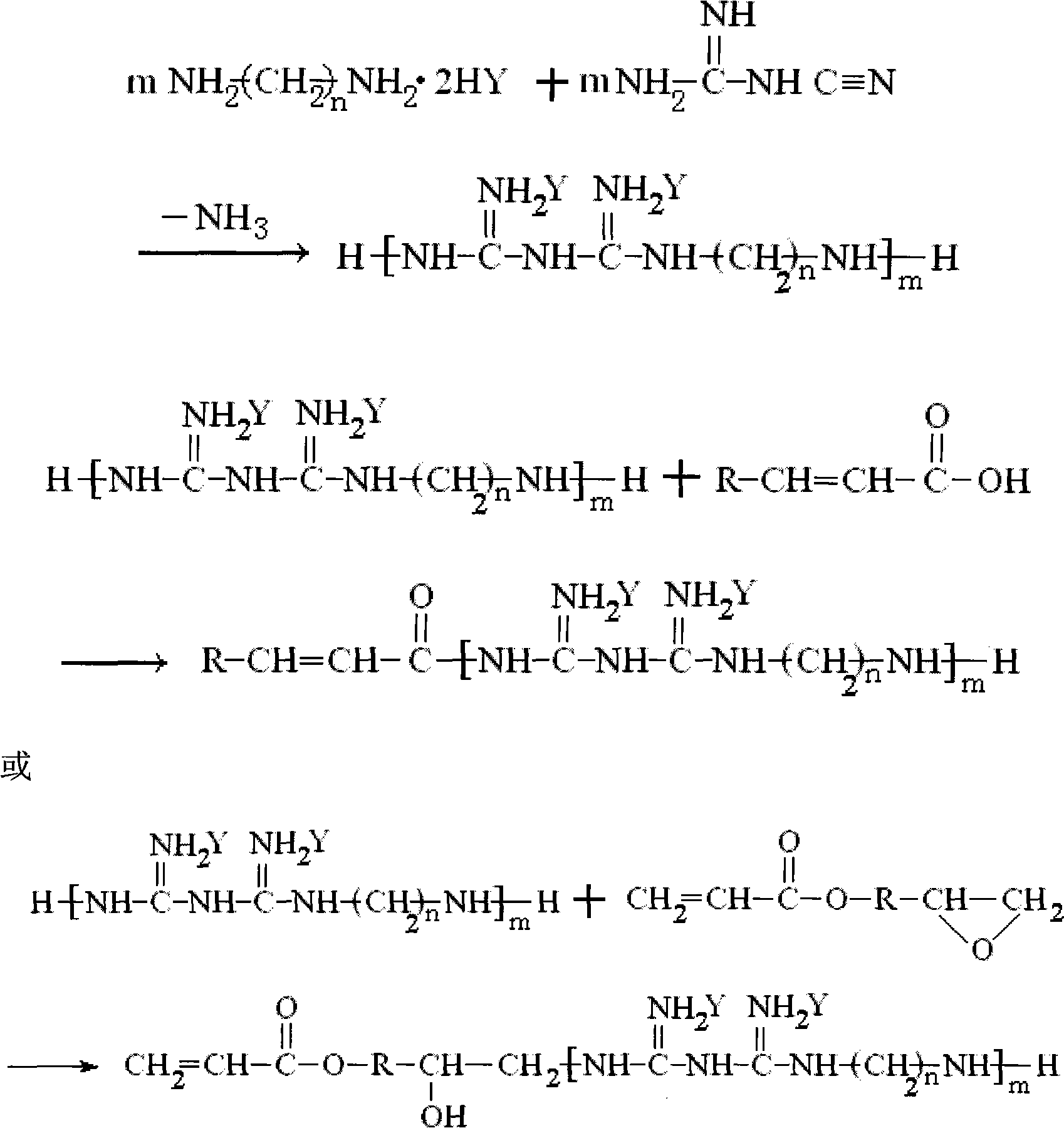

The invention relates to a polyolefin functional master batch, a preparation method thereof and use thereof. The functional master batch is prepared by blending a polyolefine resin, a guazatine oligomer, an olefin monomer, an initiator and the like and by a method of solvent graft, solid phase graft or melt graft and has a structural formula below, wherein in the formula, R represents the guazatine oligomer grafted to molecular chains of the polyolefin, and T may be hydrogen, chlorine, methyl, or phenyl. Compared with the prior art, by blending the functional master batch prepared by the invention with the corresponding polyolefin, various products, including fibers, thin films, water pipes and other plastic products, which have high antimicrobial performance and long-lasting effect and is safe and nontoxic to human bodies can be manufactured; and meanwhile, the acidic dye and disperse dye uptake of polyolefin fibers can be improved greatly, and the surface polarity, antistatic performance and paint film adhesion of polyolefin materials can be improved.

Description

technical field The invention relates to the technical field of high molecular polymer polymerization and processing, in particular to a polyolefin functionalized masterbatch and its preparation method and application. Background technique Guanidine-based polymers (including monoguanide and biguanide salts) are one of the bioactive polymers. Guanidine-based derivatives are widely used as environmental fungicides in food factories, pharmaceutical factories, hospitals, etc., and are also used in cosmetics and textiles. , which has high-efficiency and broad-spectrum antibacterial properties, can inhibit and kill microorganisms including bacteria, molds, viruses, etc., and is safe and non-toxic to the human body. For example, British Patent GB 2182245 discloses a polyhexamethylene bisguanidine hydrochloride as an antibacterial agent; Japanese patents JP 05209195, JP 05209197, and JP 05209196 use polyhexamethylene bisguanidine hydrochloride as water treatment Purifying agent, t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F255/00D01F8/06C08L23/12

Inventor 管涌郑安呐危大福胡福增王书忠李书召

Owner SHANGHAI FUYUAN PLASTICS SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com