Vacuum heat expansion forming process of rotor shielding sleeve of nuclear main pump

A shielding sleeve and nuclear main pump technology, applied in the field of nuclear power, can solve the problems of high dimensional accuracy and roundness, large residual stress of the workpiece, complex process flow, etc., and achieve stable forming quality, elimination of residual stress, and good surface finish. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

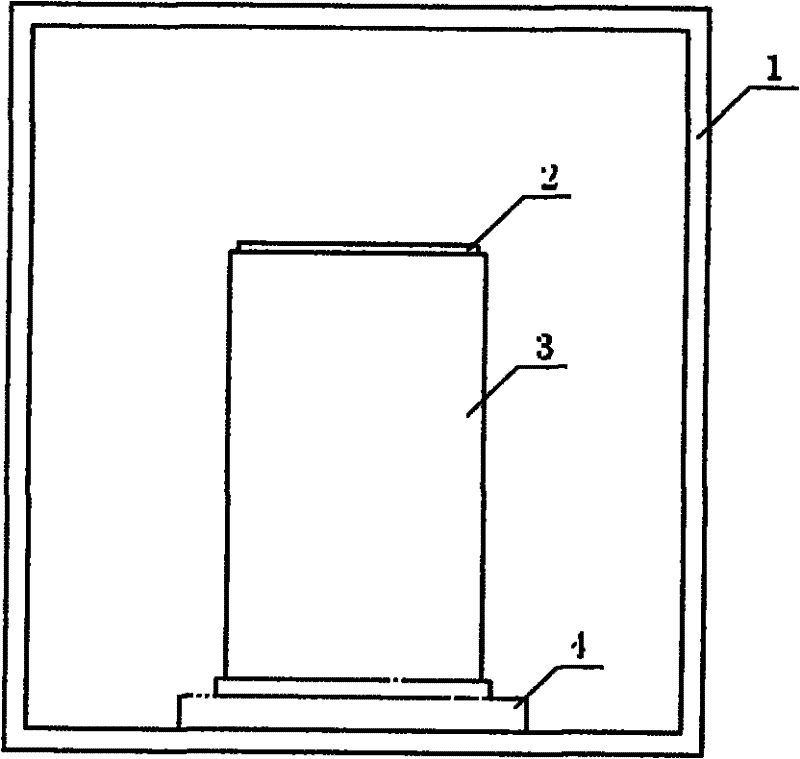

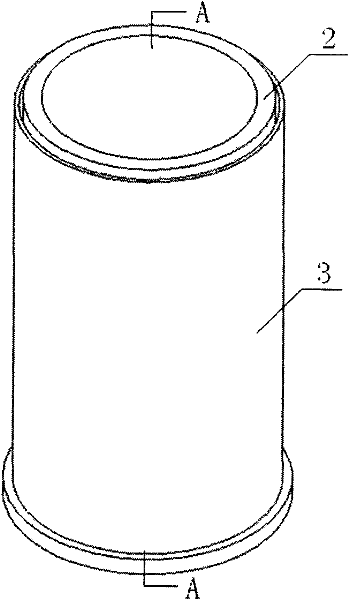

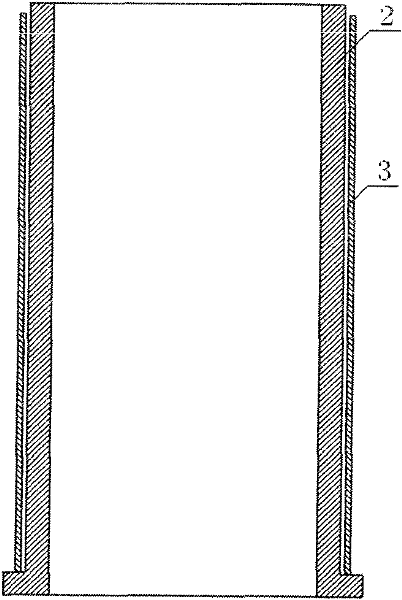

[0022] figure 1 , figure 2 and image 3 Among them, the rotor shielding sleeve 3 is set on the outside of the mold 2 and seated on the boss of the mold 2. The two are placed together on the packing table 4 in the vacuum heat treatment furnace 1, and the rotor shielding sleeve 3, the mold 2 and the packing table The axes of 4 are located on the same central line.

[0023] Figure 4 The vacuum thermal expansion process diagram of the nuclear main pump rotor shielding sleeve is shown. The process is divided into four stages: room temperature furnace loading, heating, heat preservation and furnace cooling.

[0024] Apply the above-mentioned device, and according to the above-mentioned vacuum thermal expansion process of the nuclear main pump rotor shielding sleeve 3, to realize the correction of the nuclear main pump rotor shielding sleeve 3, the specific operation is as follows:

[0025] First, put the rotor shielding sleeve 3 on the outside of the mold 2 at room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com