Method for preparing GaN-based pattern substrate template

A graphic substrate and template technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of complex process, expensive equipment, high cost, etc., and achieve the effect of simple preparation, low cost and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0032] As shown in FIGS. 1 to 5 , this embodiment is described by taking the preparation method of a submicron-scale patterned GaN substrate on a sapphire substrate as an example.

[0033] The preparation method of the GaN-based graphic substrate template of the present embodiment comprises the following steps:

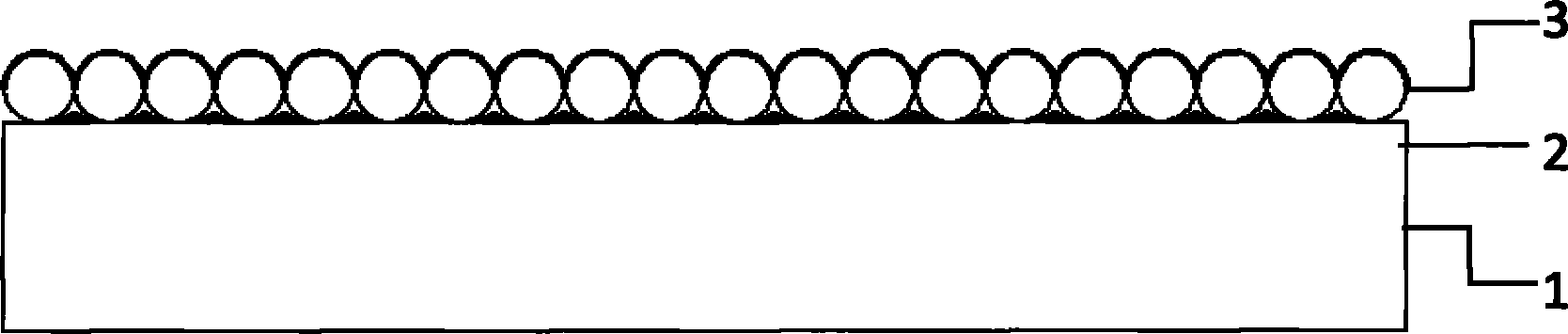

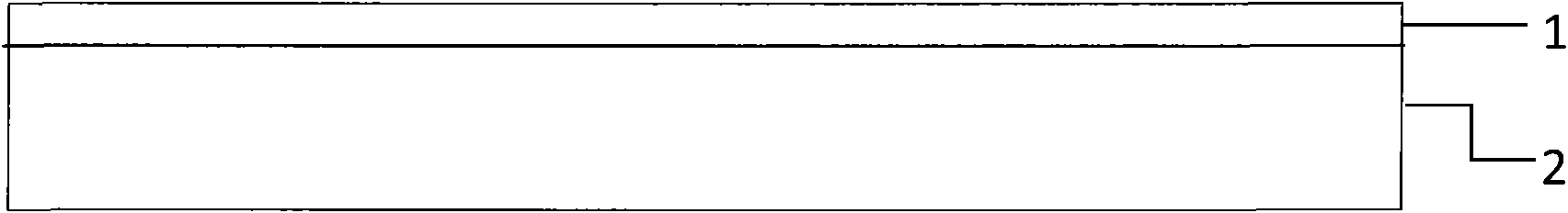

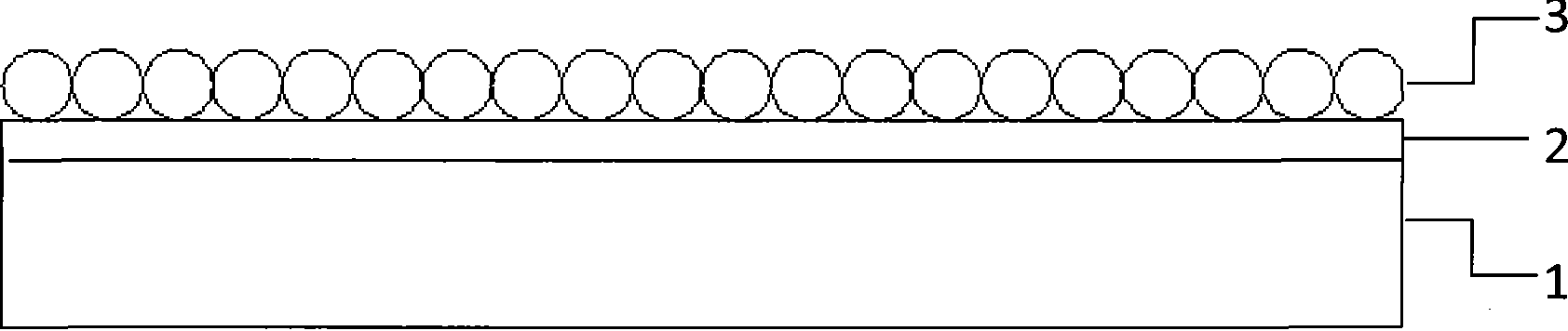

[0034] Step 1: A GaN film with a thickness of 2 microns is grown on a sapphire substrate 1 by MOCVD as a GaN template 2 for nitride growth, as shown in FIG. 1 .

[0035] Step 2: Then, mix the polystyrene microspheres with ethanol to prepare a mixed solution, and spin-coat the mixed solution on the surface of the GaN template 2, and the polystyrene microspheres will gather into a monolayer structure to form a microsphere layer 3 such as figure 2.

[0036] Step 3: Next, deposit 10nm metallic gold on the surface of the sample by means of electron beam evapora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com