Production line for lithium fluorocarbon button cell

A button-type battery and lithium carbon fluoride technology, which is applied in the field of equipment for manufacturing button-type batteries, can solve problems that have not yet been reported, and achieve the effects of simplifying process steps, saving time, and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the embodiments and the drawings, but the claims of the present invention are not limited by the specific embodiments.

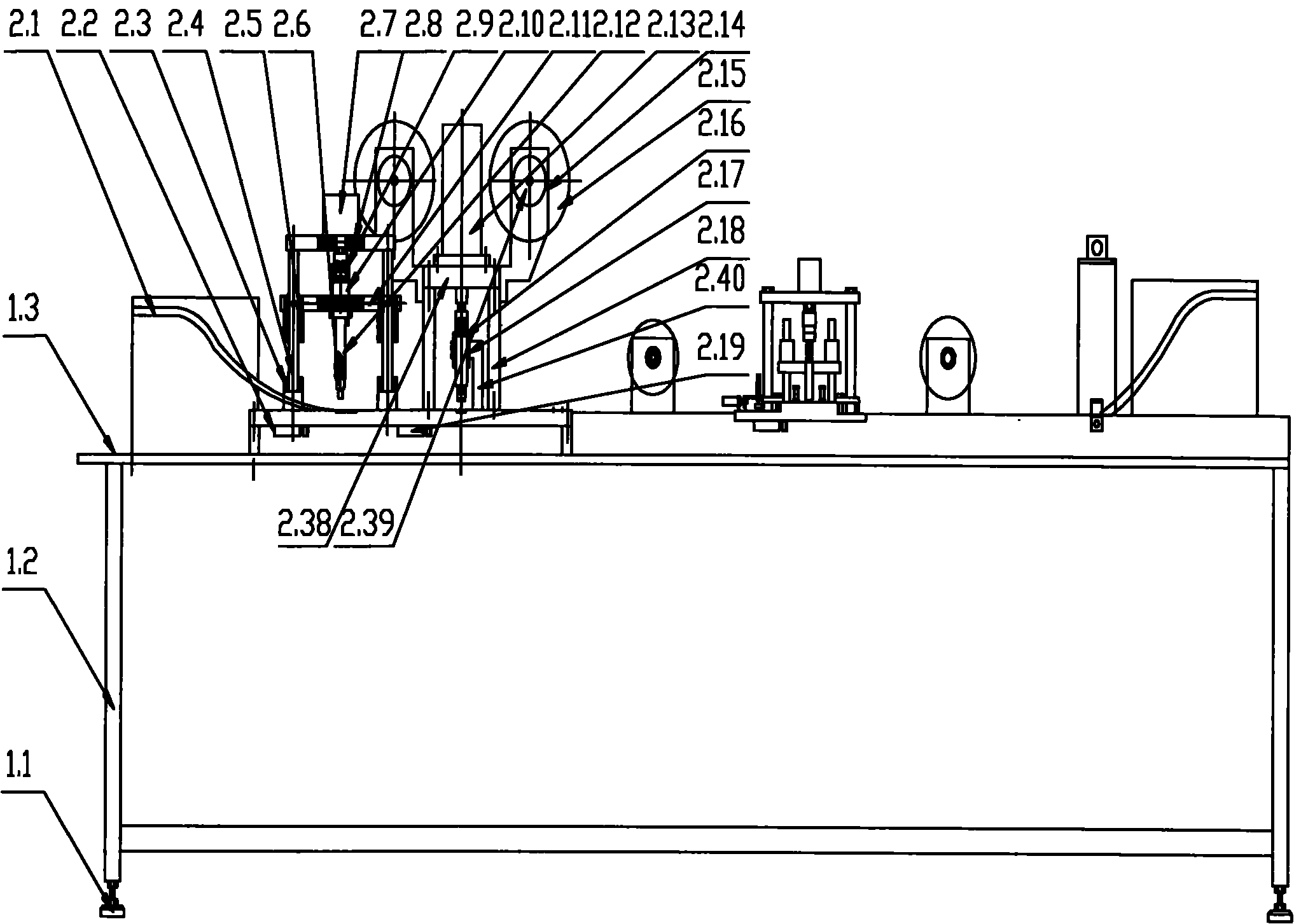

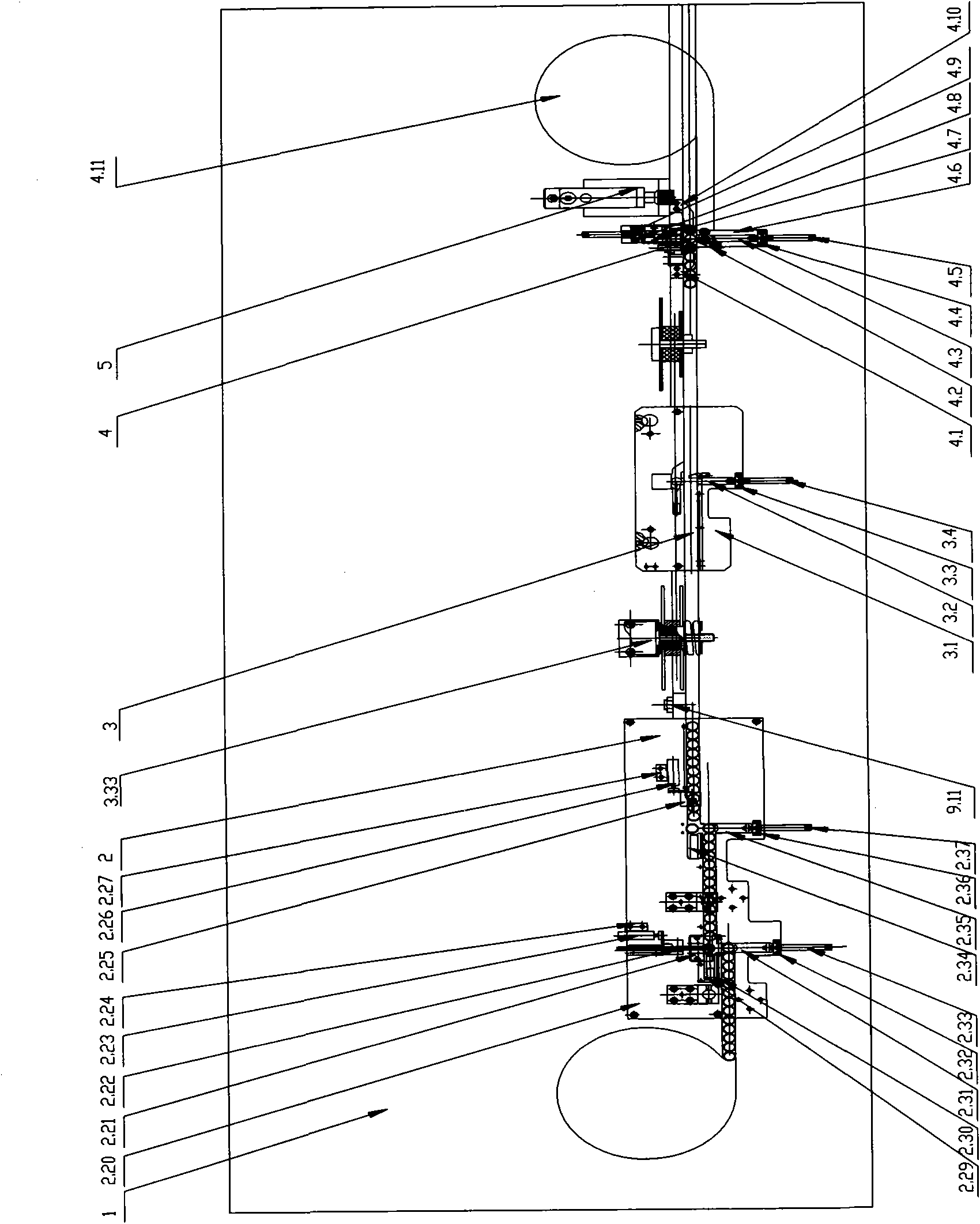

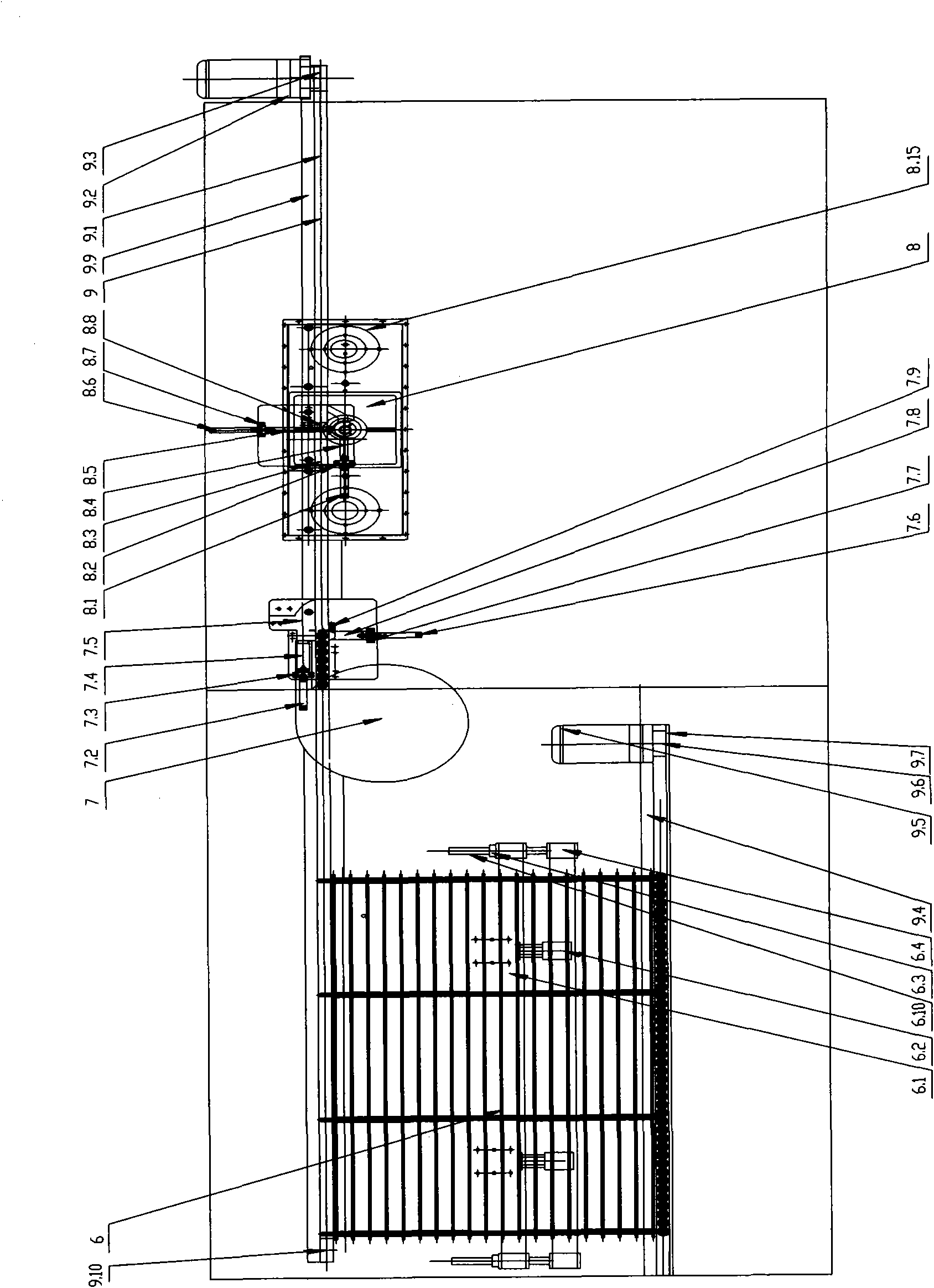

[0038] The lithium fluorocarbon button battery production line designed by the present invention (hereinafter referred to as the production line, see Figures 1-9) includes frame assembly 1, lithium sheet cutting mechanism 2, paper cutting mechanism 3, carbon fluoride upper mechanism 4, liquid injection The mechanism 5, the infiltration mechanism 6, the positive electrode casing mechanism 7, the sealing mechanism 8, the main transmission mechanism 9, the pneumatic control system 10, the electrical control system 11 and the control program.

[0039] The frame assembly 1 (see Figures 1 and 3) includes a large workbench 1.3, a bracket 1.2 fastened to its lower surface, and a foot 1.1 screwed to the bracket 1.2. The foot 1.1 can adjust the entire machine Level; the cutting and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com