Super capacitor energy-storage type elevator driver

A technology of capacitive energy storage and supercapacitors, which is applied to elevators in buildings, systems for storing electric energy, and electrical components, etc., can solve the problems of difficult detection of feedback energy, difficult control, and increased elevator costs, etc., to achieve The effect of simple control, easy implementation, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

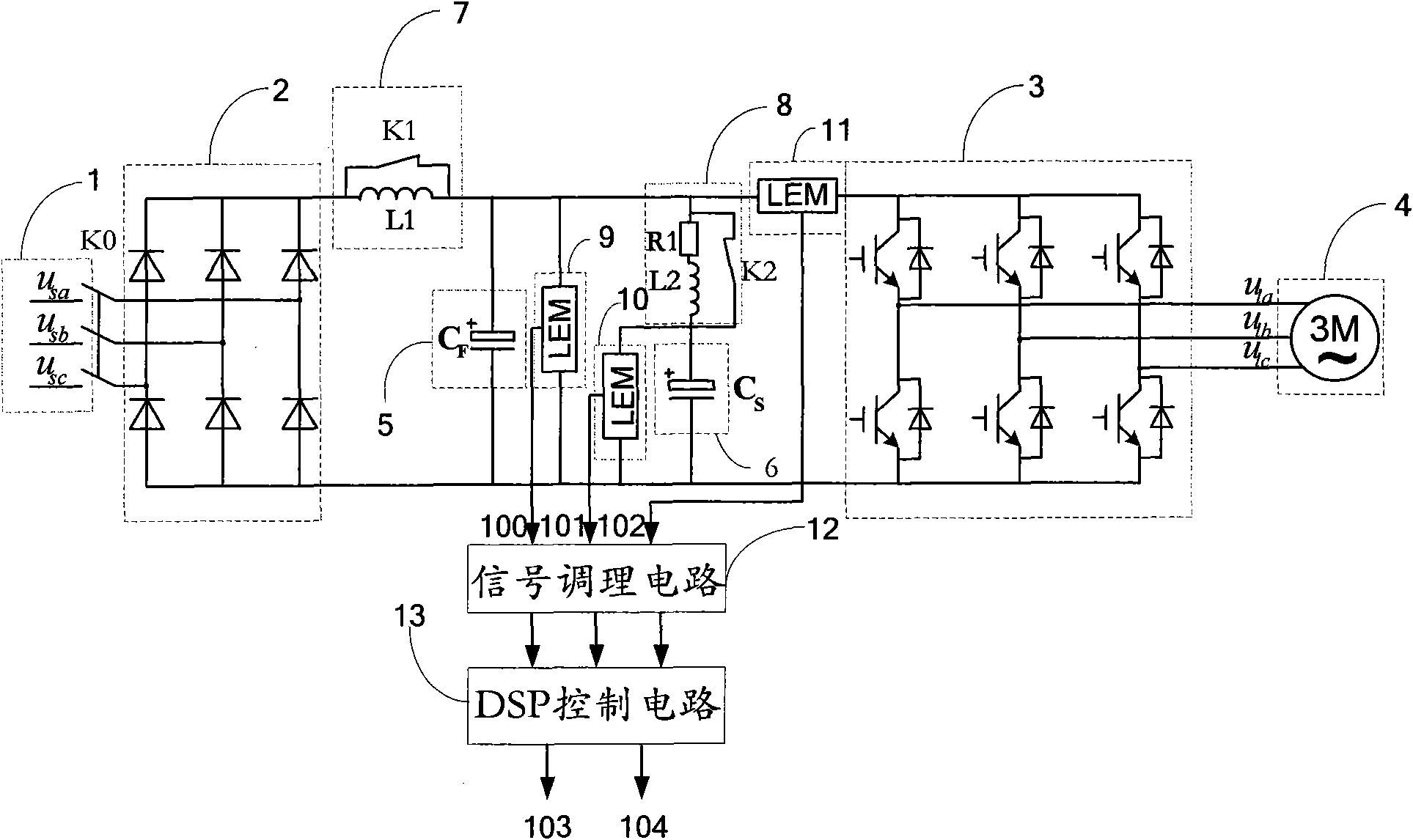

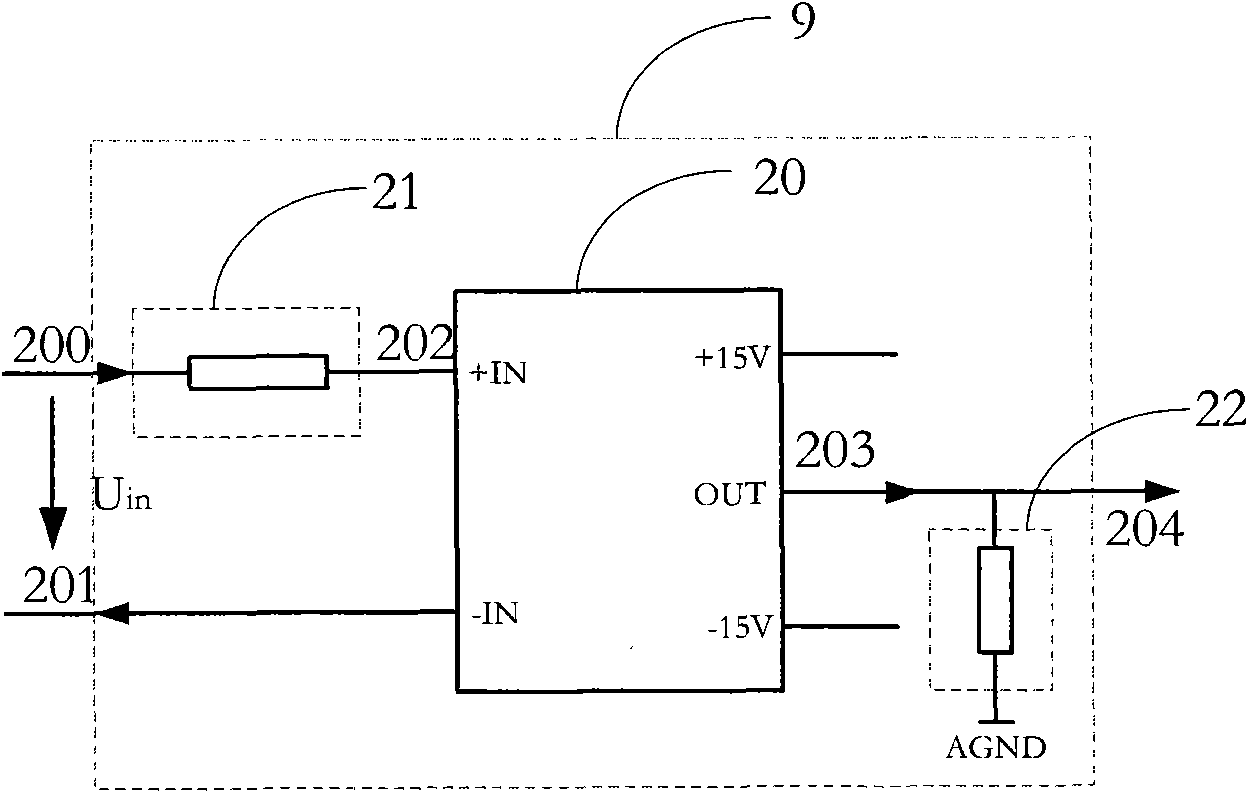

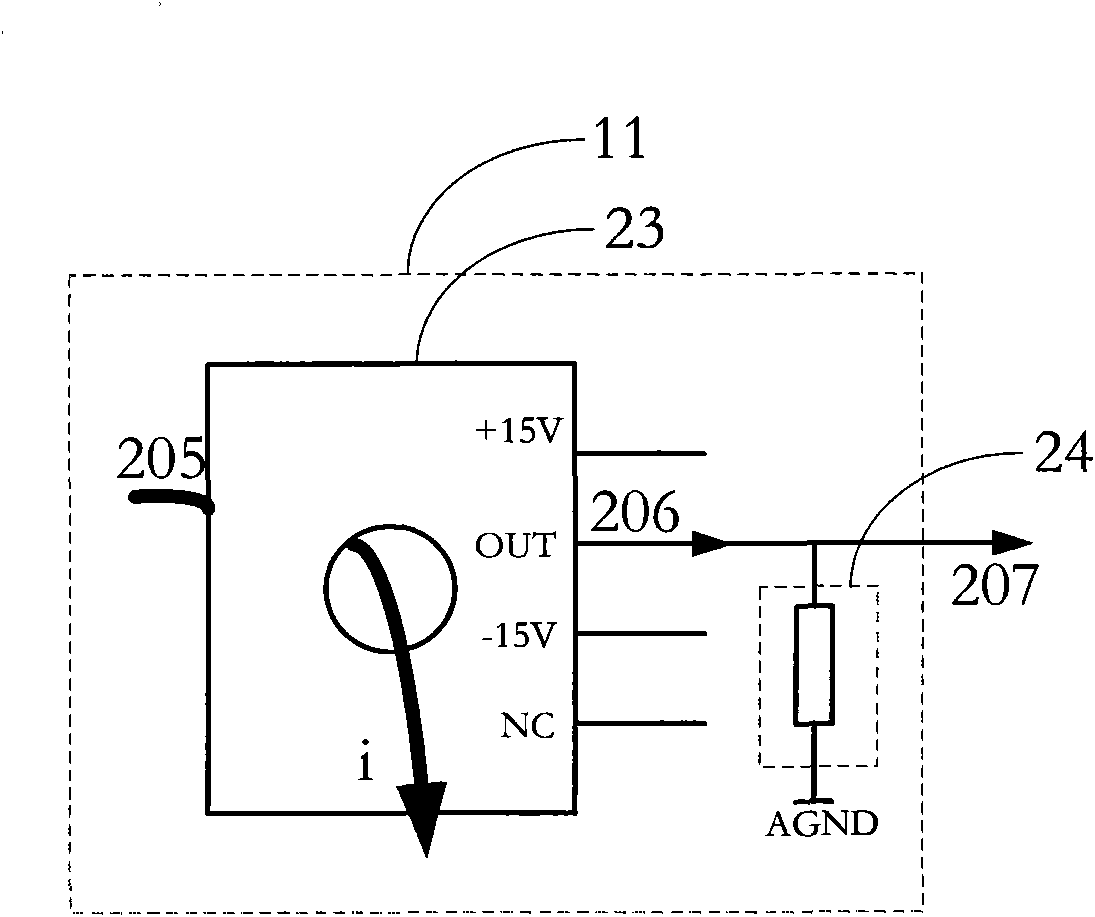

[0032] Such as figure 1 As shown, the supercapacitor energy storage type elevator driver provided by the present invention can realize energy feedback, storage and reuse while completing the elevator drive, and its system structure includes: a diode connected to the three-phase grid 1 with three-phase uncontrollable Rectifier 2, three-phase inverter composed of IGBT anti-parallel diode modules, three-phase AC traction motor 4, voltage stabilization filter capacitor 5, super capacitor bank 6, first and second current limiting circuits 7 and 8, DC The first voltage detection circuit 9 at the side, the second voltage detection circuit 10 at the supercapacitor group end, the DC bus current detection circuit 11, the signal conditioning circuit 12, and a set of control circuits 13 with DSP as the control core.

[0033] Wherein, the three-phase uncontrollable rectifier 2 and the first current-limiting circuit 7 constitute the pre-charging circuit in the present invention, which is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com