Method for preparing hollow silicon dioxide microspheres

A technology of silicon dioxide and microspheres, which is applied to the preparation of silicon dioxide, microspheres, silicon oxide, etc., can solve the problems of complicated steps, high price, increased cost, etc., and achieves simple preparation process, simplified synthesis procedure, and easy control. and the effect achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

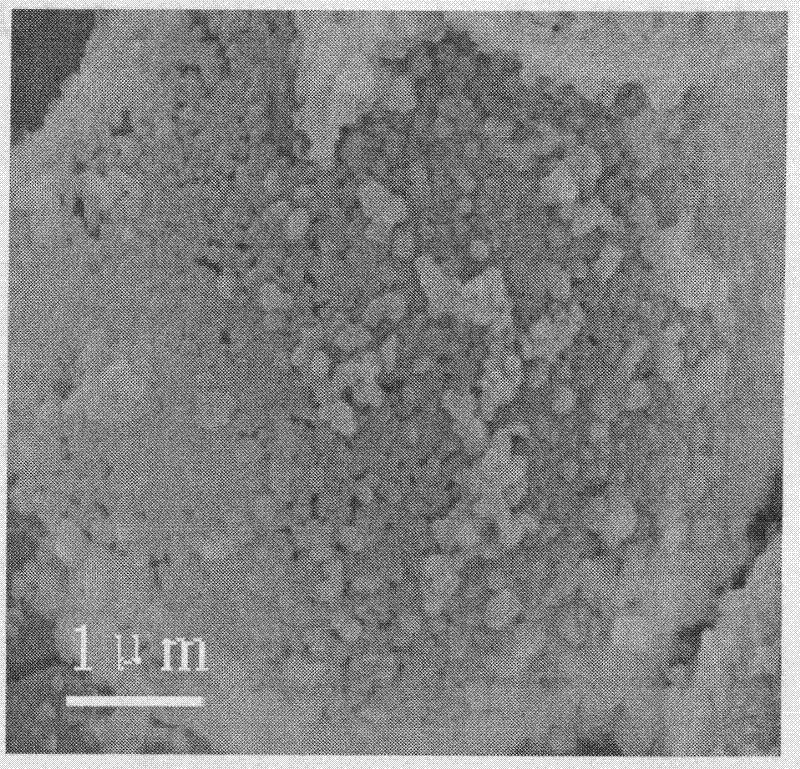

Image

Examples

Embodiment 1

[0018] First, add 65ml ethanol and 5ml water into the beaker, magnetically stir for 10min, add 5ml 25% ammonia water and continue stirring for 5min, then add 7.5ml ethyl orthosilicate, react for 1min and quickly add 7g polystyrene microspheres at room temperature Continue to stir the reaction for 2h and then end the synthesis reaction. The reaction mixture was filtered with suction and washed until the clear liquid after the filtering was free of foam; dried at room temperature for 3 days; the dried powder was heated to 550°C at a heating rate of 1°C / min, and kept for 6 hours. The furnace was cooled to room temperature, and samples were collected.

Embodiment 2

[0020] First add 65ml of ethanol and 5ml of water into the beaker, magnetically stir for 10min, add 5ml of 25% ammonia water and continue stirring for 30min, then add 10ml of ethyl orthosilicate, react for 1min and quickly add 2g of polystyrene microspheres, at room temperature Continue to stir the reaction for 2 hours and then end the synthesis reaction. The reaction mixture was filtered with suction and washed until the clear liquid after the filtering was free of foam; dried at room temperature for 3 days; the dried powder was heated to 550°C at a heating rate of 1°C / min, and kept for 6 hours. The furnace was cooled to room temperature, and samples were collected.

Embodiment 3

[0022] First add 65ml ethanol and 5ml water into the beaker, magnetically stir for 10min, add 10ml 25% ammonia water and continue to stir for 5min, then add 10ml ethyl orthosilicate, after reacting for 1min, quickly add 3.5g polystyrene microspheres at room temperature Continue to stir the reaction for 3 hours and then end the synthesis reaction. The reaction mixture was filtered with suction and washed until the clear liquid after the filtering was free of foam; dried at room temperature for 3 days; the dried powder was heated to 550°C at a heating rate of 1°C / min, and kept for 6 hours. The furnace was cooled to room temperature, and samples were collected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com