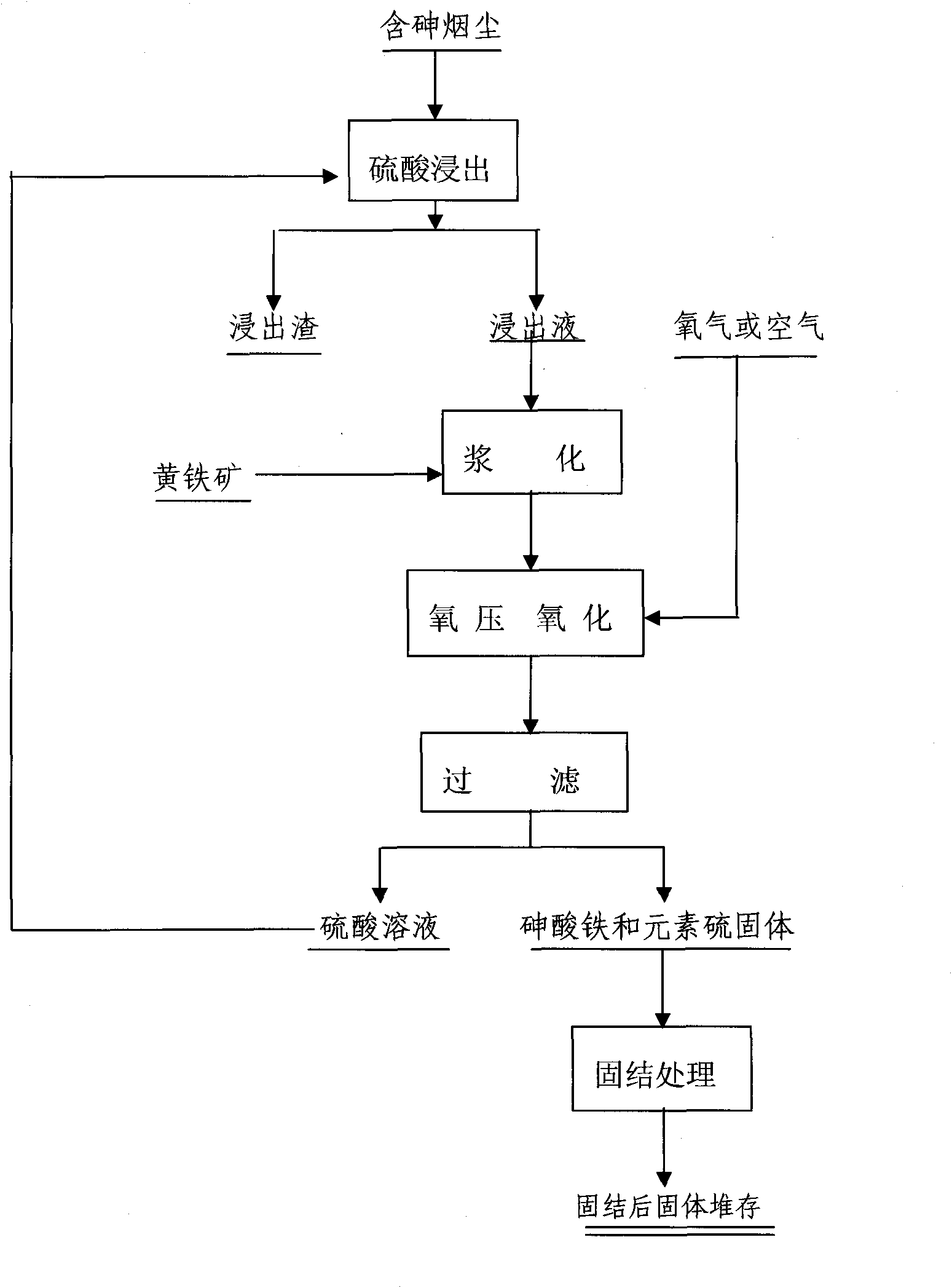

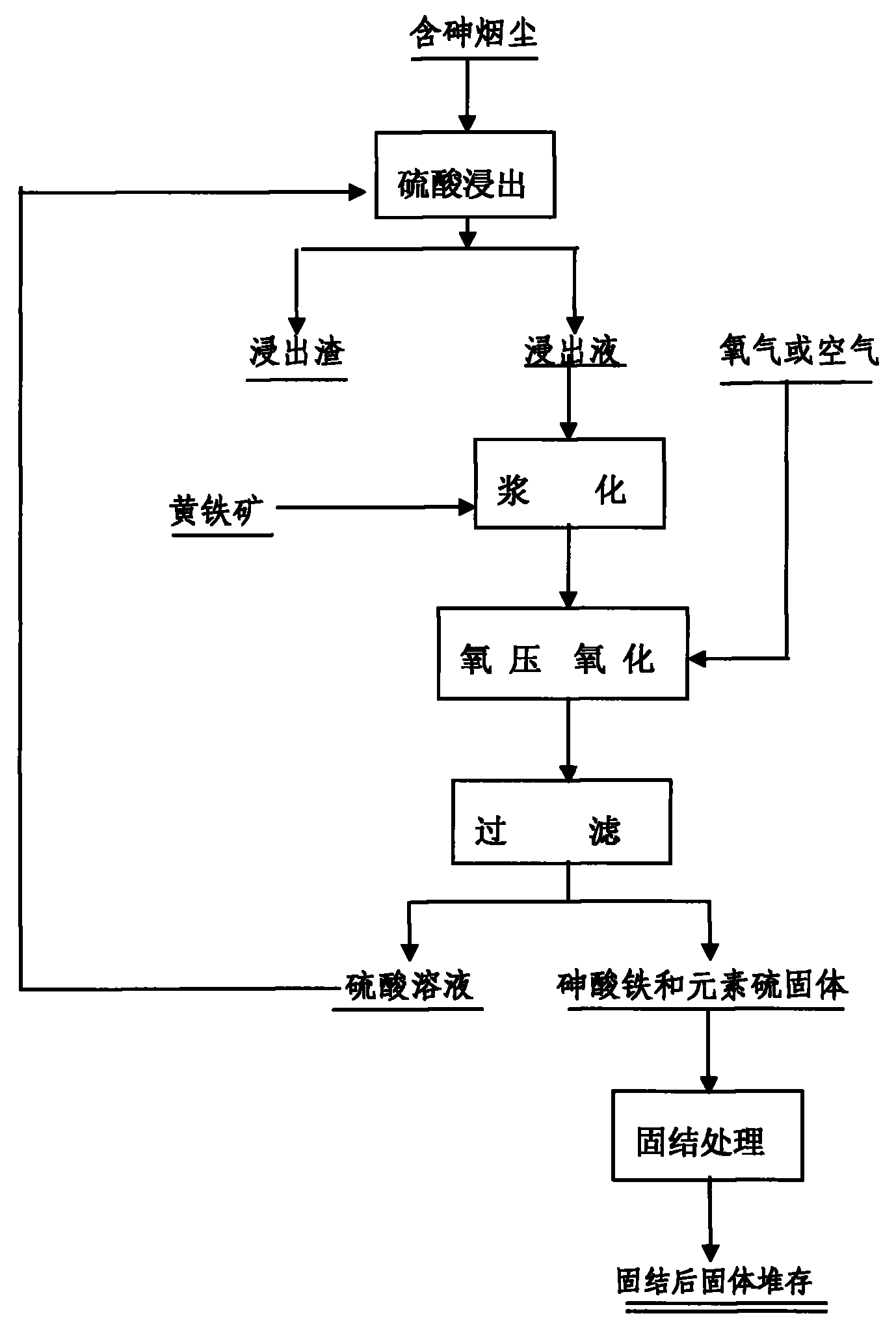

Method for treating arsenic-containing smoke dust

A treatment method and technology for arsenic soot, applied in the preparation/purification of sulfur, arsenate/arsenite, etc., can solve problems such as high energy consumption, and achieve the effects of eliminating pollution, solving open circuit problems, and having a wide range of raw material sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Smoke composition: As48.34%; pyrite composition: Fe43.28%, S36.57%, particle size -100 mesh.

[0022] 1.0Kg of arsenic-containing fumes were leached with a sulfuric acid solution with a concentration of 21.74g / L to obtain 11.2L of leaching solution with an arsenic concentration of 41.03g / L. Add 1.19Kg of pyrite powder into the leaching solution and stir for 0.5 hours, then add it into a closed stirring reactor, feed oxygen to the oxygen partial pressure of 1.0Mpa, heat to 130°C, stir for 3 hours, and filter to obtain iron arsenate and element Sulfur mixed solid 2.11Kg, 19.73g / L sulfuric acid solution 10.3L.

[0023] Take 1kg of the mixed solid and heat it to 135°C, press it into a block, cool to room temperature and consolidate to obtain a hydrophobic solid with high strength and harmless to the environment; press 1 kg of the mixed solid into a block, heat it to 135°C and keep it warm for 20 minutes, and cool Consolidate at room temperature to obtain a hydrophobic soli...

Embodiment 2

[0025] Smoke composition: As48.34%; pyrite composition: Fe43.28%, S36.57%, particle size -100 mesh.

[0026] Leach 1.0Kg of arsenic-containing dust and sulfuric acid solution with a concentration of 12.74g / L to obtain 11.4L of leach solution with an arsenic concentration of 38.59g / L. Add 1.52Kg of pyrite powder to the leach solution and stir for 0.5 hours, then add airtight stirring reaction Into the vessel, feed oxygen to the oxygen partial pressure of 1.5Mpa, heat to 100°C, stir for 4 hours, and filter to obtain 10.4L of sulfuric acid solution of 2.53Kg and 11.43g / L mixed solid of iron arsenate and elemental sulfur.

[0027] Take 1kg of the mixed solid, heat it to 150°C, press it into a block, cool to room temperature and consolidate, and obtain a hydrophobic solid with high strength and harmless to the environment; take 1kg of the mixed solid, press it into a block, heat it to 150°C and keep it warm for 10 minutes, and cool Consolidate at room temperature to obtain a hydrop...

Embodiment 3

[0029] Smoke composition: As48.34%; pyrite composition: Fe43.28%, S36.57%, particle size -100 mesh.

[0030] Leach 1.0Kg of arsenic-containing dust and sulfuric acid solution with a concentration of 28.43g / L to obtain 11.2L of leaching solution with an arsenic concentration of 42.3g / L. Add 1.52Kg of pyrite powder to the leaching solution and stir for 0.5 hours, then add airtight stirring reaction Into the vessel, feed oxygen to the oxygen partial pressure of 0.7Mpa, heat to 160°C, stir for 2 hours, and filter to obtain 1.69Kg, 29.57g / L sulfuric acid solution of mixed solid of iron arsenate and elemental sulfur 10.1L.

[0031] Take 1kg of the mixed solid, heat it to 120°C, press it into a block, cool to room temperature and solidify, and obtain a hydrophobic solid with high strength and harmless to the environment; take 1kg of the mixed solid, press it into a block, heat it to 120°C and keep it warm for 30 minutes, and cool Consolidate at room temperature to obtain a hydrophobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com