Liquid metal working medium purification device

A liquid metal, purification device technology, applied in nuclear engineering, reactor fuel elements, reactors, etc., can solve the problems of inability to work at the same time, low purification efficiency, waste of space, etc., so as to improve the total impurity capture capacity and prolong the service life. , the effect of reducing the depth of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

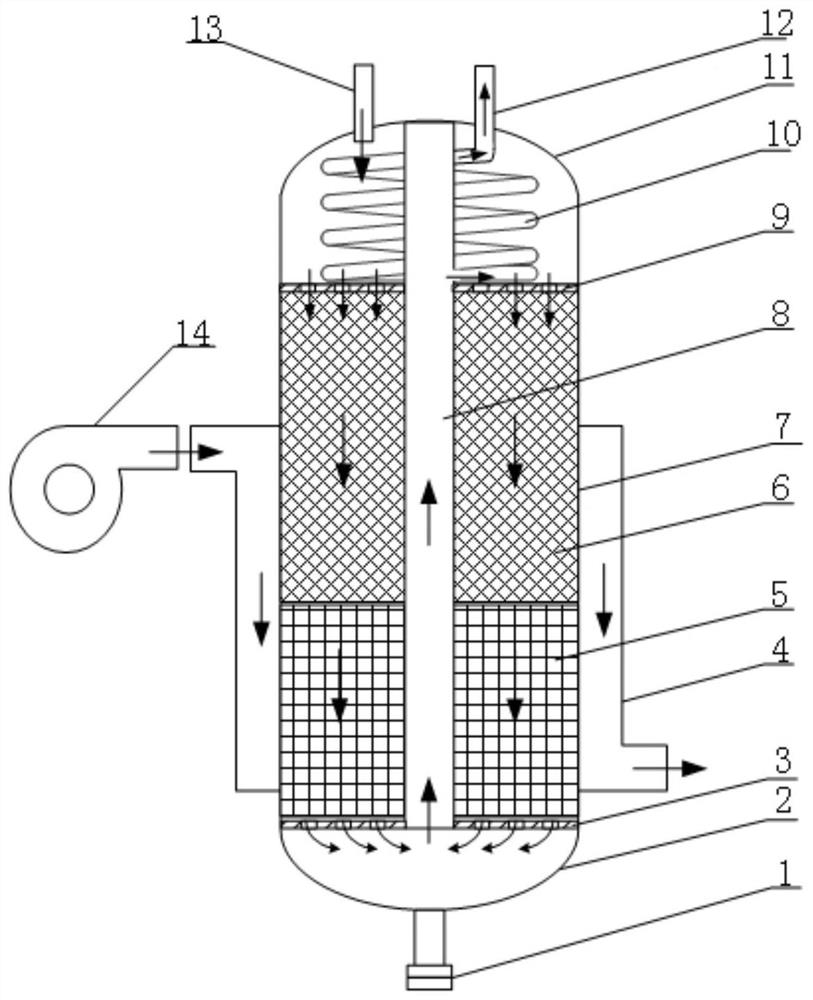

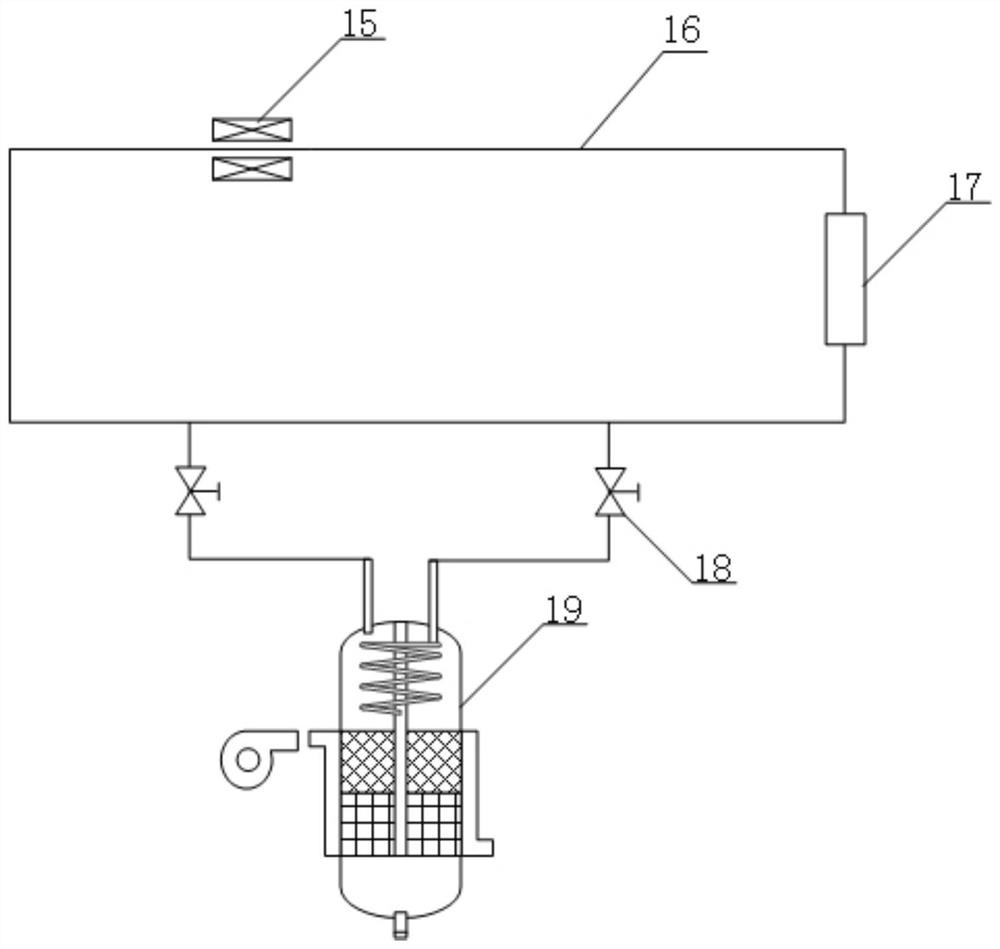

[0030] Such as figure 1 As shown, the present invention provides a liquid metal working fluid purification device, including a cylinder, a purification screen assembly 6, a crystallization screen assembly 5 and a cooling structure; the cylinder is provided with an inlet pipe 13 and an outlet pipe 12, The purification screen assembly 6 and the crystallization screen assembly 5 are arranged in the cylinder; the cooling structure is arranged outside the cylinder and cools the crystallization screen assembly 5; the liquid metal working fluid enters through the inlet pipe 13 The cylinder body passes through the purification screen assembly 6 and the crystallization screen assembly 5 in sequence, and then is discharged from the cylinder body through the outlet pipe 12 .

[0031] In this embodiment, except for the wire mesh component, the rest of the compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com