Hot melt adhesive for quick joint coating of metallic pipeline and preparation method thereof

A technology for metal pipes and hot melt adhesives, applied in the direction of adhesives, graft polymer adhesives, adhesive types, etc., can solve the problems of unsatisfactory construction fluidity, poor weather resistance of anti-corrosion hot melt adhesives, etc. Vast, good high and low temperature resistance, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

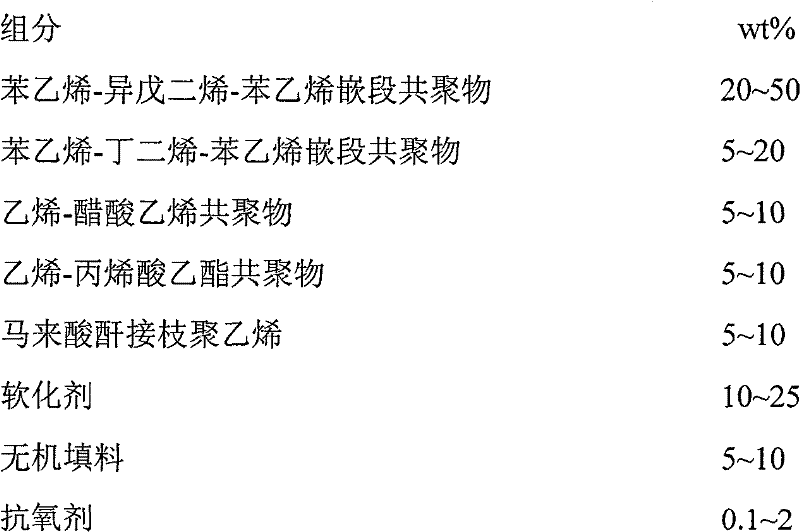

[0032] Component proportion of anticorrosive hot melt adhesive for repairing metal pipes (wt%):

[0033] Styrene-isoprene-styrene block copolymer (SIS) 30

[0034] Styrene-butadiene-styrene block copolymer (SBS) 5

[0035] Ethylene-vinyl acetate copolymer (EVA) 5

[0036] Ethylene-ethyl acrylate copolymer (EEA) 5

[0037] Maleic anhydride grafted polyethylene (M-g-PE) 5

[0038] Naphthenic oil 15

[0039] C 5 Petroleum resin 15

[0040] Terpene phenol resin 14

[0041] Inorganic filler 5

[0042] Antioxidant 1

[0043] According to the measurement, the three components of SIS, SBS and naphthenic oil are oil-filled at 80°C for 30 minutes; then a certain proportion of antioxidant is added, kneaded in a kneader at high speed, and the temperature is set to 170°C; after stirring evenly Add EVA, EEA, Mg-PE, C in sequence 5 Petroleum resin, terpene phenol resin, filler, continue to stir and knead at 170°C at high speed. Finally, the uniformly kneaded hot melt adhesive is extruded through a twin-sc...

Embodiment 2

[0045] Component proportion of anticorrosive hot melt adhesive for repairing metal pipes (wt%):

[0046] Styrene-isoprene-styrene block copolymer (SIS) 35

[0047] Styrene-butadiene-styrene block copolymer (SBS) 5

[0048] Ethylene-ethyl acrylate copolymer (EEA) 5

[0049] Maleic anhydride grafted polyethylene (M-g-PE) 5

[0050] Naphthenic oil 17

[0051] C 5 Petroleum resin 14

[0052] Polymerized rosin 10

[0053] Inorganic filler 8

[0054] Antioxidant 1

[0055] According to the measurement, the three components of SIS, SBS and naphthenic oil are oil-filled at 80°C for 30 minutes; then a certain proportion of antioxidant is added, kneaded in a kneader at high speed, and the temperature is set to 170°C; after stirring evenly Add EEA, Mg-PE, C in sequence 5 Petroleum resin, polymerized rosin, and fillers are continuously stirred and kneaded at 170°C at high speed. Finally, the uniformly kneaded hot melt adhesive is extruded through a twin-screw extruder.

Embodiment 3

[0057] Component proportion of anticorrosive hot melt adhesive for repairing metal pipes (wt%):

[0058] Styrene-isoprene-styrene block copolymer (SIS) 30

[0059] Styrene-butadiene-styrene block copolymer (SBS) 5

[0060] Maleic anhydride grafted polyethylene (M-g-PE) 10

[0061] Naphthenic oil 15

[0062] C 5 Petroleum resin 10

[0063] Terpene phenol resin 10

[0064] Polymerized rosin 10

[0065] Inorganic filler 8

[0066] Antioxidant 2

[0067] According to the measurement, the three components of SIS, SBS and naphthenic oil are oil-filled at 80°C for 30 minutes; then a certain proportion of antioxidant is added, kneaded in a kneader at high speed, and the temperature is set to 170°C; after stirring evenly Add Mg-PE and C in sequence 5 Petroleum resin, terpene phenol resin, polymerized rosin, filler, continue to stir and knead at 170℃ at high speed. Finally, the uniformly kneaded hot melt adhesive is extruded through a twin-screw extruder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com