Low quenching sensitive aluminum alloy added with Ag and Ge at same time

A technology of quenching sensitivity and aluminum alloy, which is applied in the field of low quenching sensitivity aluminum alloy and low quenching sensitivity aluminum alloy adding Ag and Ge at the same time, which can solve the problems of reducing cooling rate, difficulty in obtaining cooling rate, reducing quenching stress, etc. , to achieve the effects of reducing quenching sensitivity, delaying nose tip time, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

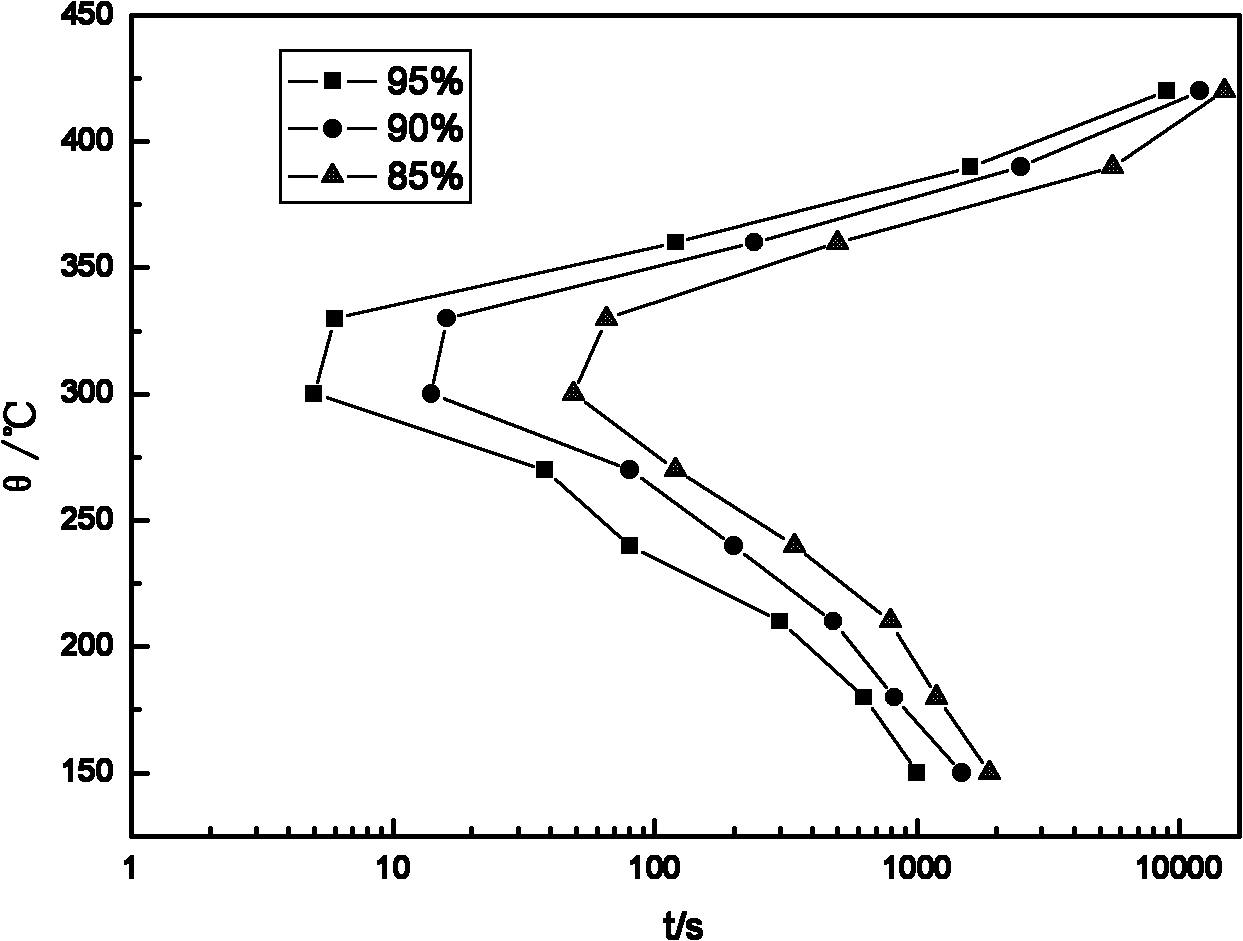

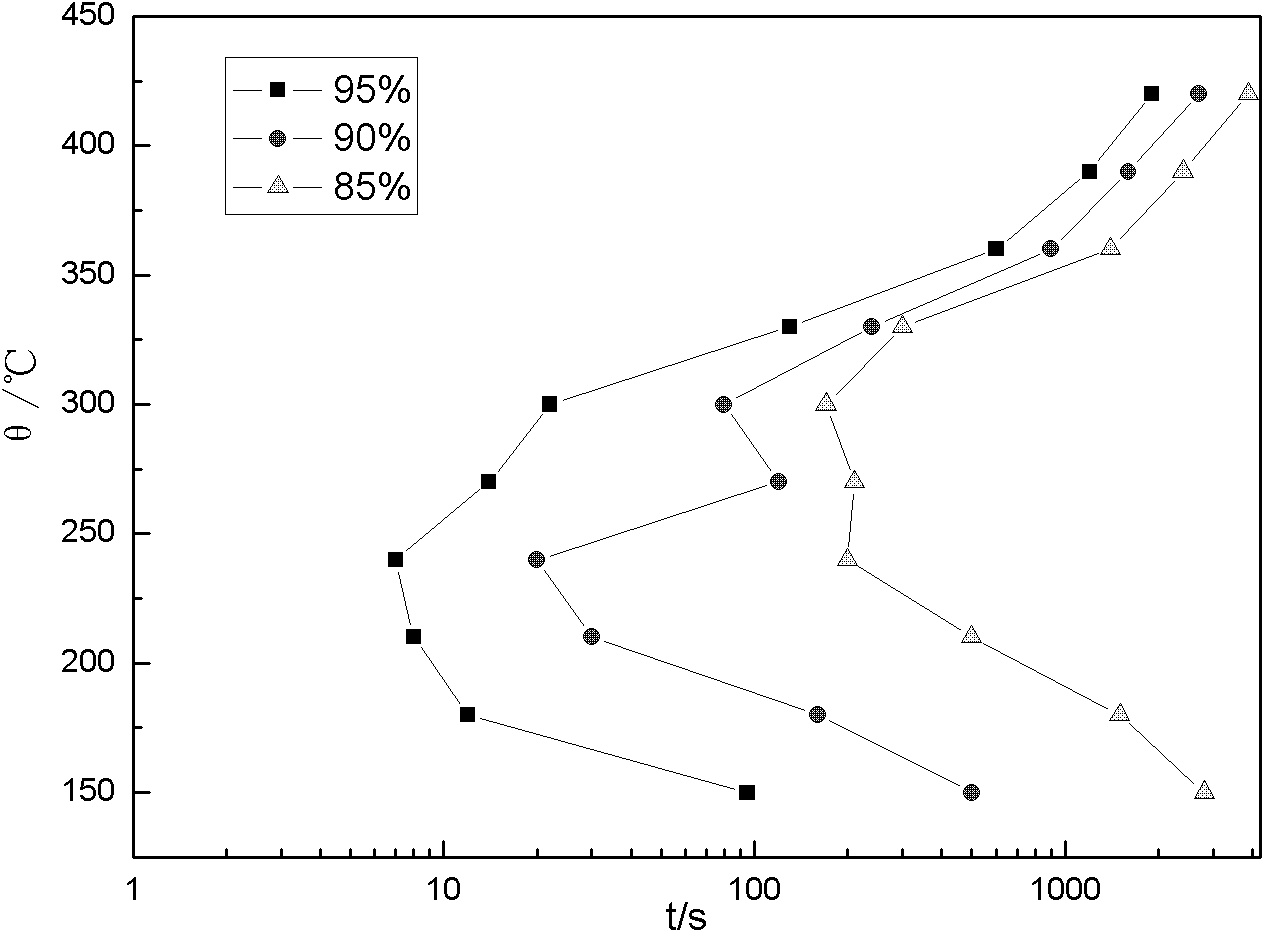

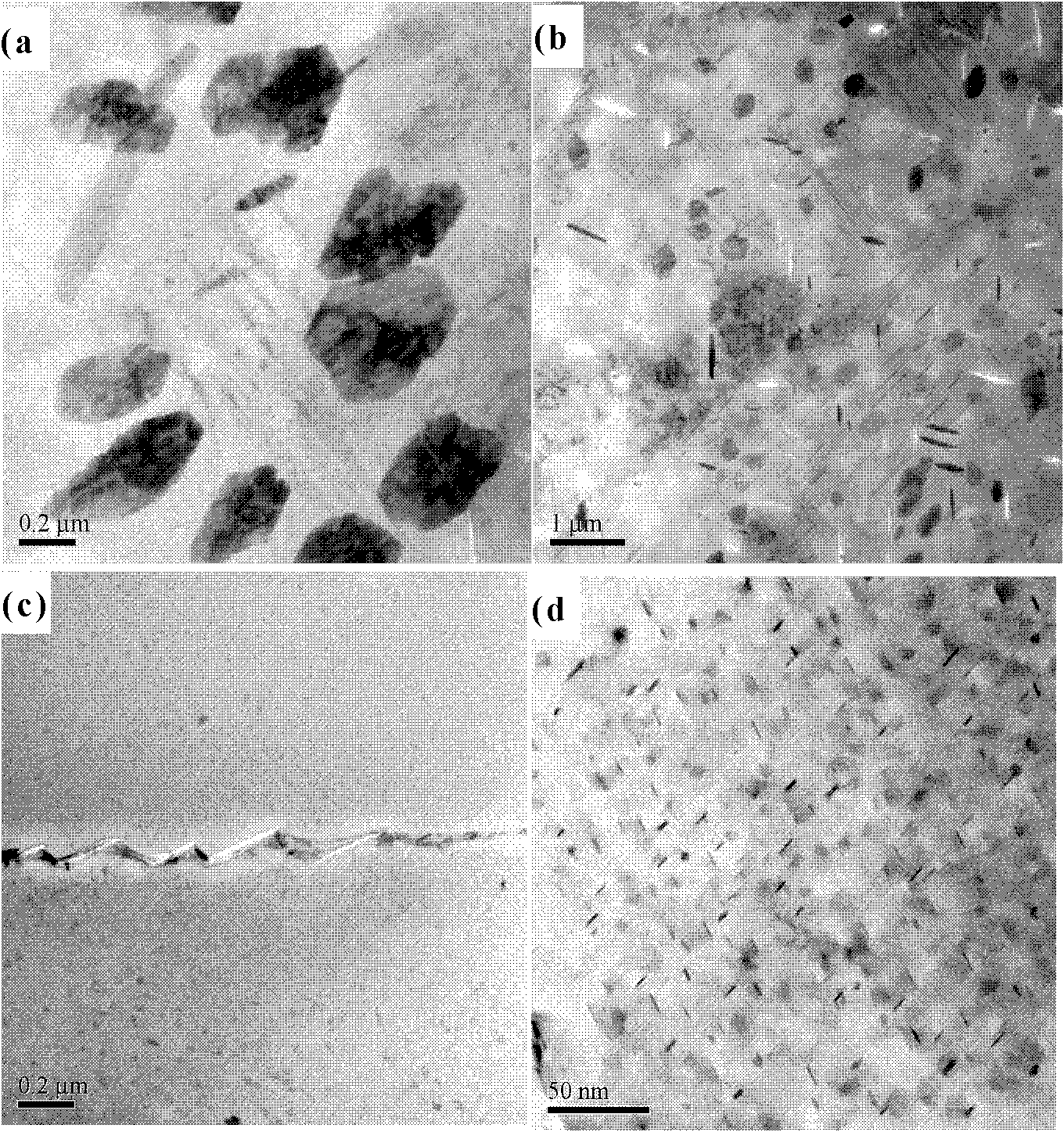

Embodiment 1

[0032] The alloy composition is 6.0% Zn, 1.1% Mg, 1.6% Cu, 0.13% Zr, 0.08% Ti, 0.5% Ge, 0.5% Ag, and the balance is Al. The purity of Ge and Ag is greater than or equal to 99.99%, and it is smelted into an ingot Blank. After homogenization treatment at 450°C / 24h+455°C / 24h, hot rolling into a 4mm thick plate. After the sample was solidified at 470℃ / 1h, compared with the alloy without Ge and Ag, the alloy with 0.5% Ge and 0.5% Ag was added, not only the incubation period of the second phase precipitation was prolonged, but the nose tip time of the TTP curve was delayed by 2 seconds, and the tensile strength and yield strength were increased by 4MPa and 27MPa.

Embodiment 2

[0034] The alloy composition is 6.5% Zn, 1.3% Mg, 1.3% Cu, 0.13% Zr, 0.08% Ti, 0.1% Ge, 0.1% Ag, and the balance is Al. The purity of Ge and Ag is greater than or equal to 99.99%, and it is smelted into an ingot Blank. After homogenization treatment at 450°C / 24h+455°C / 24h, it is hot-extruded into a Φ12.5mm round bar with an extrusion ratio of 25. After the sample was solidified at 470°C / 1h, it was quenched in water and air at room temperature, and aged at 120°C / 24h. Tensile property test shows that compared with the alloy without Ag and Ge, after quenching and aging in water at room temperature, the tensile strength and yield strength of the alloy samples added with 0.1% Ge and 0.1% Ag are both higher by 10Mpa. After quenching and aging in air, the tensile strength of the alloy sample added with 0.1% Ag and 0.1% Ge is 11Mpa higher, and the yield strength is 37MPa higher.

Embodiment 3

[0036] The alloy composition is 7.0% Zn, 1.4% Mg, 1.6% Cu, 0.13% Zr, 0.08% Ti, 0.05% Ge, 0.05% Ag, and the balance is Al. The purity of Ge and Ag is greater than or equal to 99.99%, and it is smelted into an ingot Blank. After homogenization treatment at 450°C / 24h+455°C / 24h, it is hot-extruded into a Φ12.5mm round bar with an extrusion ratio of 25. After the sample was solidified at 470°C / 1h, it was quenched in water and air at room temperature, and aged at 120°C / 24h. Tensile performance test shows that compared with the alloy without Ag and Ge, after quenching and aging in water at room temperature, the tensile strength and yield strength of the alloy sample added with 0.05% Ag and 0.05% Ge are both higher by 13Mpa. After quenching and aging in air, the tensile strength of the alloy sample added with 0.05% Ag and 0.05% Ge is higher by 18Mpa, and the yield strength is higher by 60MPa.

[0037] The performance parameters of the aluminum alloys obtained in Examples 1, 2, and 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com