Cylinder-deactivation control method and device of electronic-control fuel-injection multi-cylinder internal-combustion engine

A multi-cylinder internal combustion engine and fuel injection technology, which is applied in engine control, mechanical equipment, machines/engines, etc., can solve the problem of increasing fuel consumption, inability to adapt, and difficulty in meeting the requirements of the effective working conditions of the catalytic treatment device. and other issues, to achieve the effect of reducing harmful gas emissions, improving service life, and reducing the number of frequent short-term operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

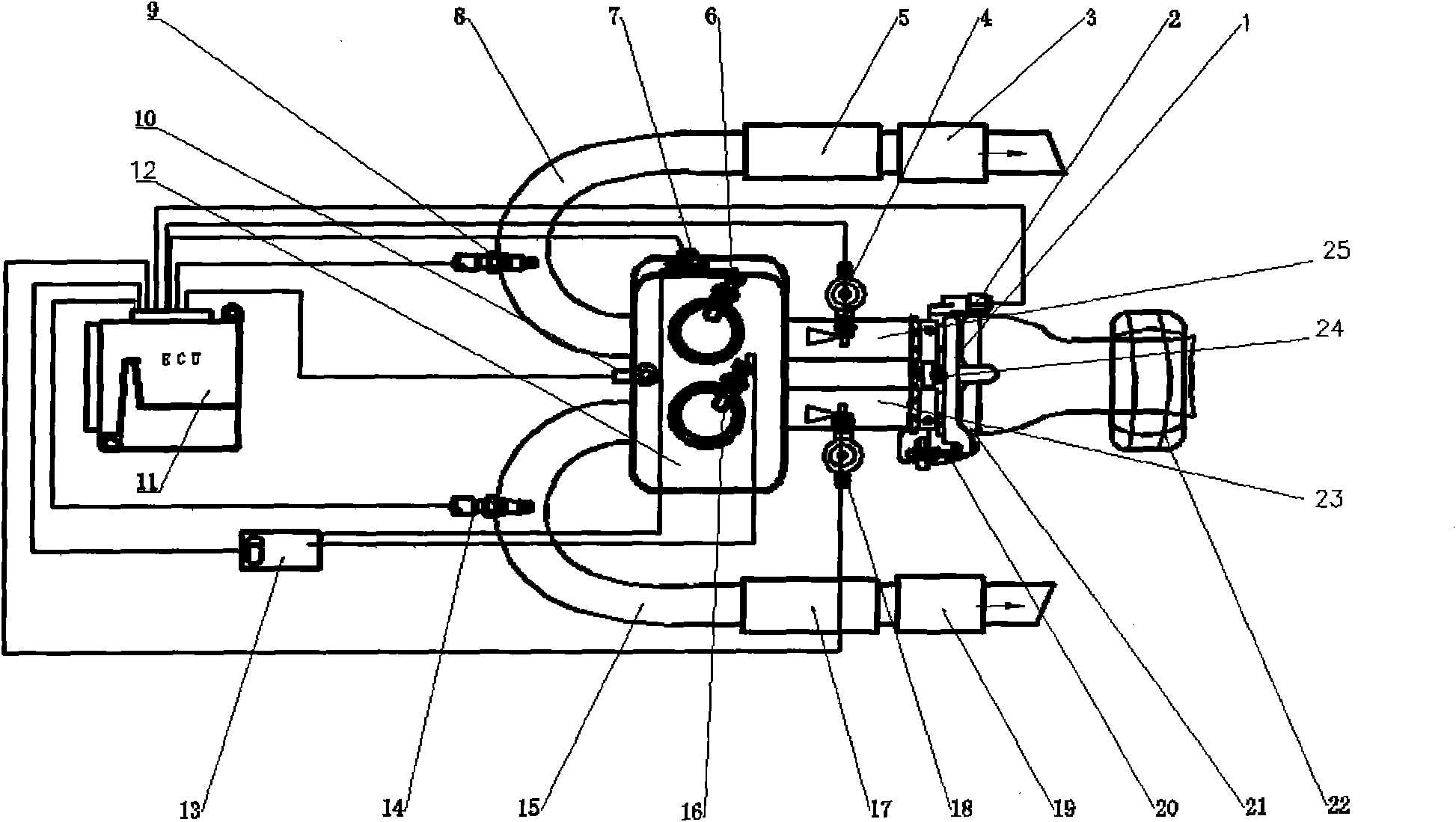

[0044] exist figure 1 In the shown embodiment, the multi-cylinder internal combustion engine is a gasoline engine with dual-cylinder electronically controlled fuel intake port injection, and the parts shared by the two cylinders include: air filter 22, throttle position sensor 2, throttle operating runner 20, rotating speed and Angle sensor 7, engine body 12, engine temperature sensor 10, electronic control unit (ECU) 11, ignition energy supply device 13, load operation runner 20, and the components used independently by the two cylinders include, the independent components of the first cylinder system include : Throttle body 1, intake port 25, fuel injector 4, spark plug 6, exhaust pipe 8, oxygen sensor 9, exhaust catalytic treatment device 5, exhaust muffler 3, etc. The independent components of the second cylinder system include: Valve body 21, intake port 23, fuel injector 18, spark plug 16, exhaust pipe 15, oxygen sensor 14, exhaust catalytic treatment device 17, exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com