Machine vision detection system for unchy yarn shape parameters

A technology of machine vision detection and shape parameters, which is applied in the field of textile industry, can solve the problems that the polar plate affects the test results, the uniformity of yarn moisture absorption affects the test results, and cannot be directly applied to the control of spinning equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

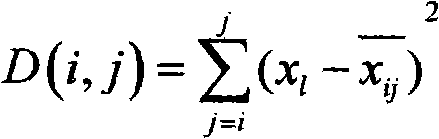

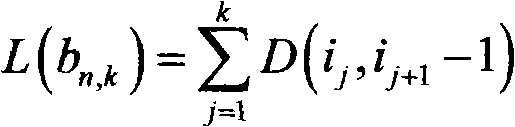

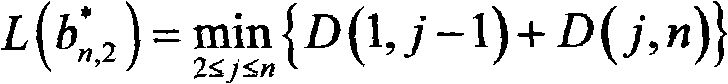

Method used

Image

Examples

Embodiment Construction

[0053] This slub yarn shape parameter machine vision detection system of the present invention adopts following hardware equipment:

[0054] Slub yarn image acquisition equipment:

[0055] Line scan CCD industrial camera 10bit 2048pixel 20KHz

[0056] PCI image acquisition card Camera Link interface

[0057] LED lighting source highlight full spectrum ring structure

[0058] Yarn motion control device PLC, stepping motor, rubber wheel pair

[0059] Slub yarn image processing equipment:

[0060] PC, Intel CPU 2.66 GHz, 2GB memory

[0061] WindowXP operating system VC++6.0 design language

[0062] Use the algorithm described in the technical proposal

[0063] In the process of slub diameter classification, it is divided into 3 categories: slub, base yarn, and cotton knot;

[0064] The algorithm can distinguish the knots from the slubs, and obtain the random sequence of slubs, spun yarns, and knots;

[0065] On this basis, count the length of the bamboo, the distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com