Photonic crystal optical fiber coupler for forming hollow light beam and preparation method thereof

A technology of photonic crystal fiber and hollow beam, which is applied in the coupling of optical waveguide, cladding optical fiber, optical waveguide light guide, etc., can solve the problems of multimode optical fiber length limitation, and achieve the effect of low cost, wide application range and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

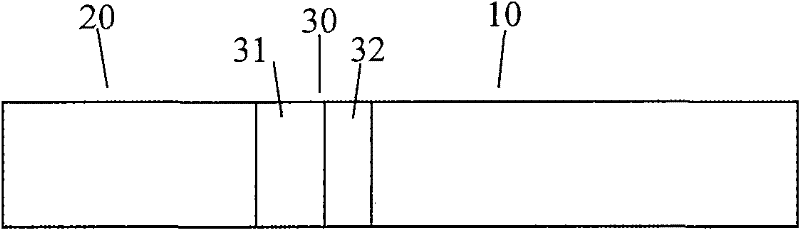

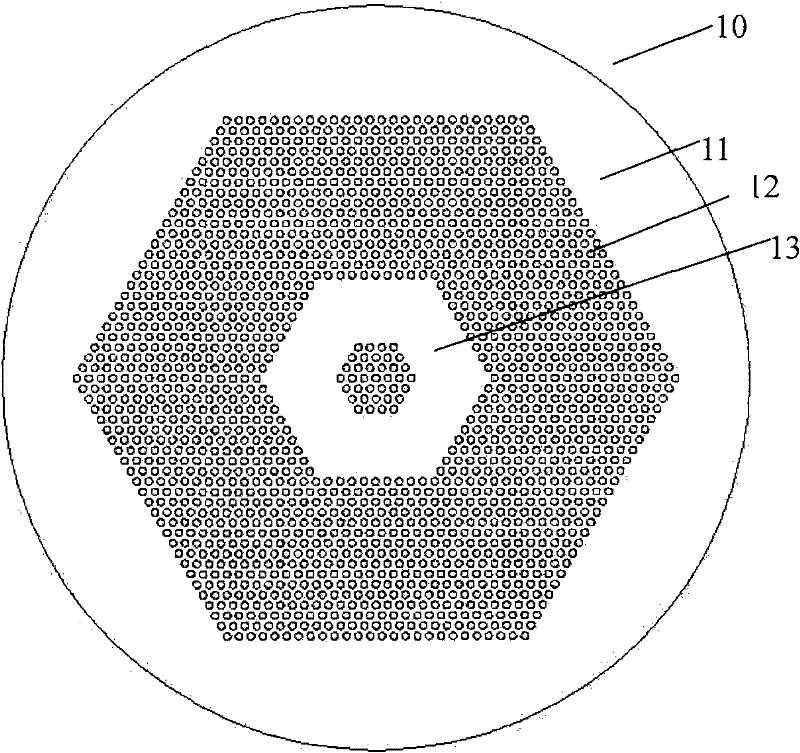

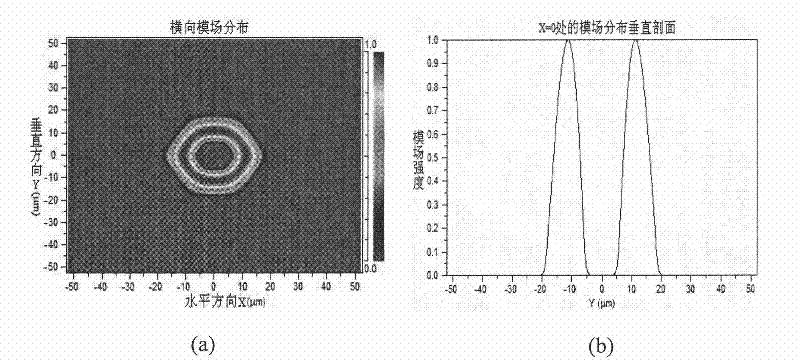

[0039] figure 1 A schematic diagram of a photonic crystal fiber coupler according to Embodiment 1 of the present invention is shown. The photonic crystal fiber coupler includes a ring-core photonic crystal fiber 10 , a single-mode fiber 20 and a fusion splicing region 30 with a fully collapsed region 31 and a gradually collapsed region 32 . figure 2 A schematic cross-sectional view of the ring-core photonic crystal fiber 10 in the photonic crystal fiber coupler in Embodiment 1 is shown. The diameter of the cladding of the ring-core photonic crystal fiber 10 is 125 μm, the background material 11 is pure quartz, the air holes 12 include air holes with a diameter of 1.2 μm arranged in a hexagon, and the distance between the centers of the holes is 2 μm, including the central air hole The number of air hole circles is 20 in total; the ring core 13 is made of pure quartz and has a hexagonal ring structure, and the distances from the center of the ring core photonic crystal fiber ...

Embodiment 2

[0044] Figure 5 A schematic diagram of a photonic crystal fiber coupler according to Embodiment 2 of the present invention is shown. The photonic crystal fiber coupler includes a ring-core photonic crystal fiber 10 , a single-mode fiber 20 and a fusion splicing region 30 with a fully collapsed region 31 and a gradually collapsed region 32 . Figure 6 A schematic cross-sectional view of the ring-core photonic crystal fiber 10 in the photonic crystal fiber coupler according to Embodiment 2 of the present invention is shown. The cladding diameter of the ring-core photonic crystal fiber 10 is 150 μm, the background material 11 is pure quartz, and the air holes 12 include large air holes with a diameter of 15 μm and small air holes with a diameter of 7.5 μm arranged at hexagonal intervals. The ring core 13 is made of fluorine-doped background material, its inner diameter is 7.5 μm, and its outer diameter is 37.95 μm. The thermal expansion coefficient of the ring core material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com