Flue gas desulfuration system for removing tar in desulfurization solution

A technology of desulfurization system and desulfurization liquid, applied in the direction of liquid separation, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of short equipment life and low quality of gypsum, and achieve the effect of preventing desulfurization efficiency and improving steam production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

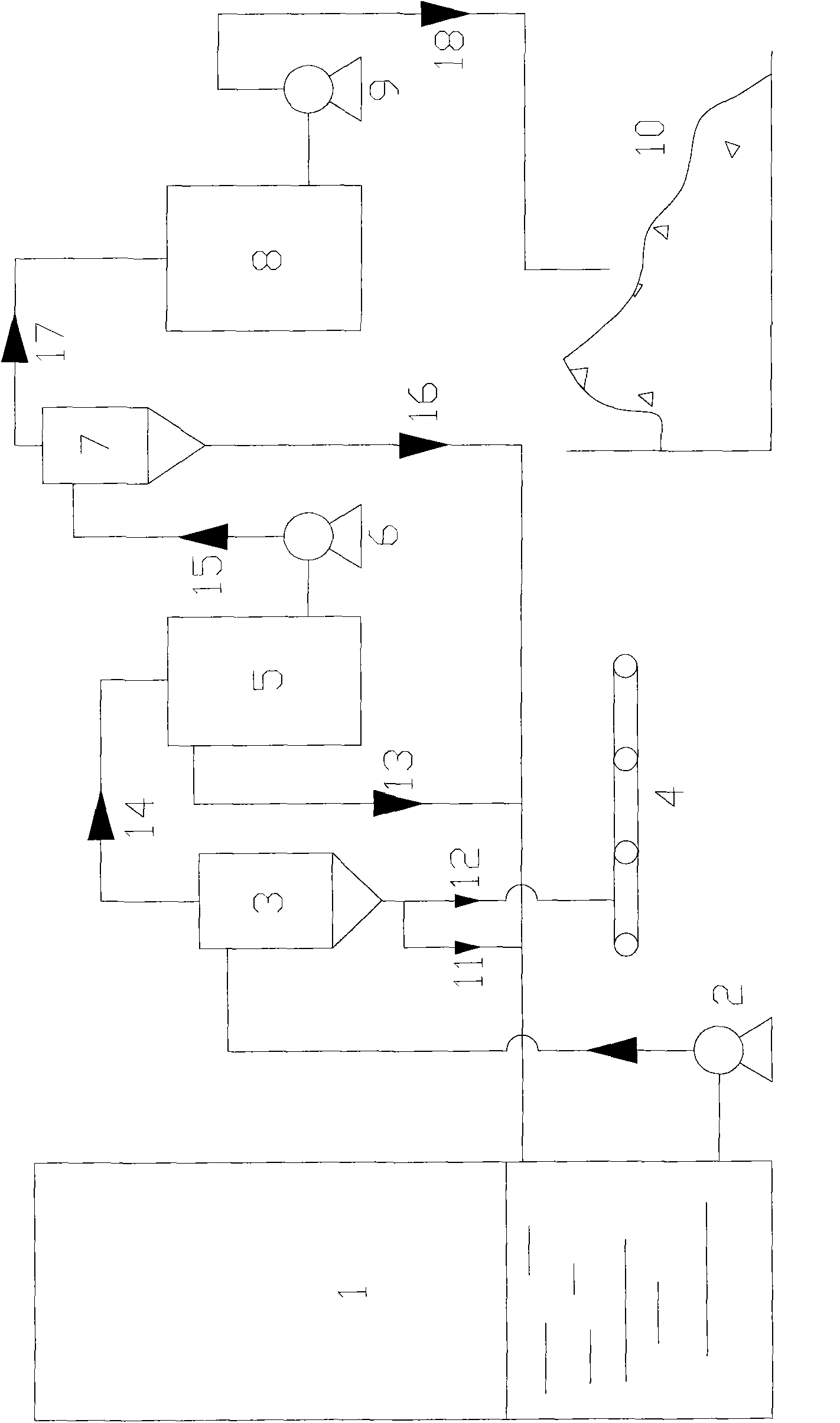

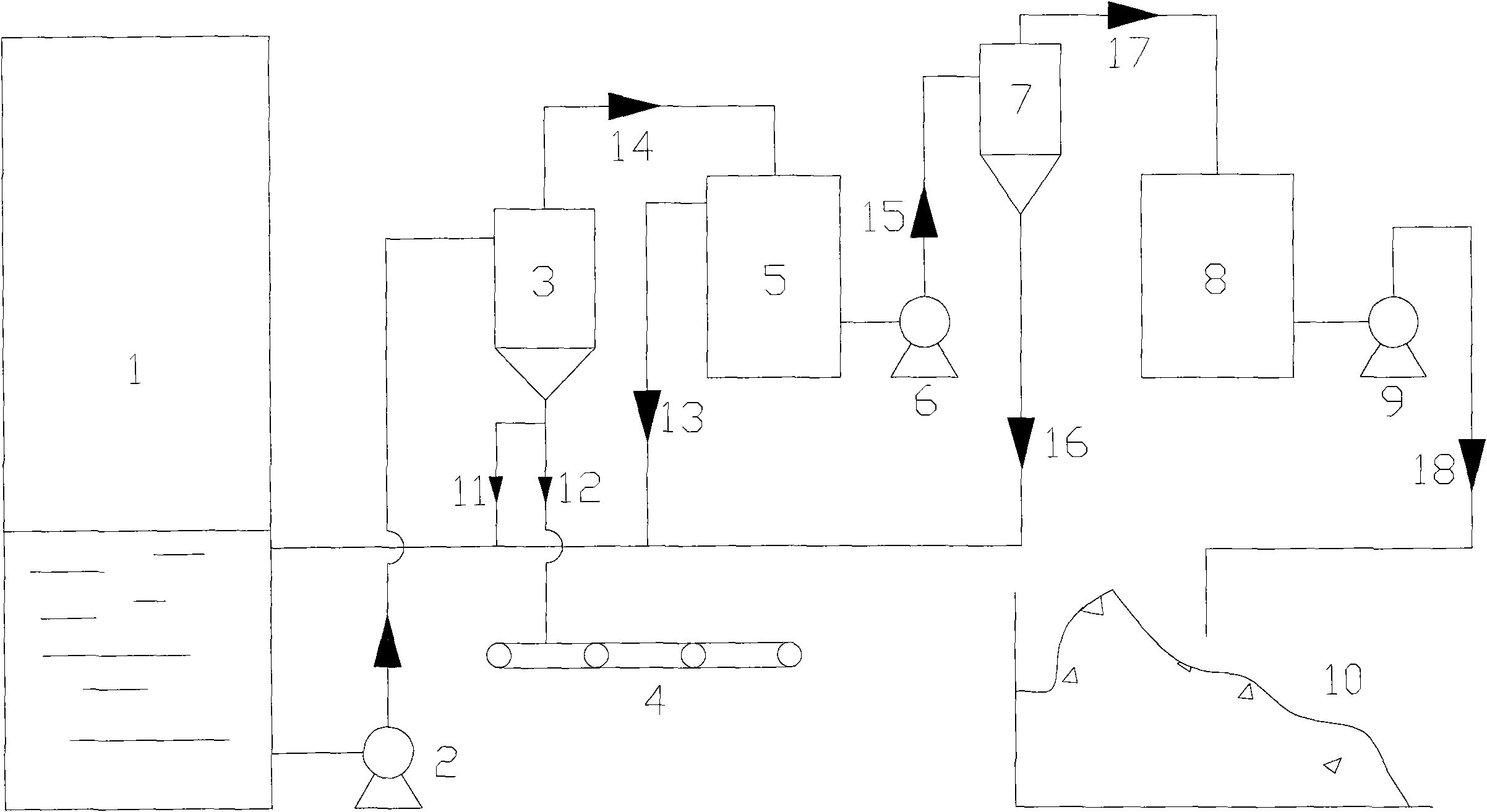

[0021] The boiler in the comparative example adopts such as figure 1 The desulfurization system shown.

[0022] The desulfurization liquid is extracted from the desulfurization tower 1 by the gypsum discharge pump 2 and sent to the primary cyclone 3. After the desulfurization liquid is centrifugally separated by the primary cyclone 3, the top flow 14 of the primary cyclone flows to the buffer tank 5 , the slurry in the buffer tank 5 overflows from the overflow position, the overflow 13 returns to the desulfurization tower 1, the bottom flow of the primary cyclone is connected to two pipelines, the first pipeline 11 returns to the desulfurization tower 1, and the second pipeline 12 is transported to the vacuum belt conveyor 4 , the wastewater treatment pump 6 extracts the slurry 15 in the buffer tank 5, and sends it to the secondary cyclone 7. After the secondary cyclone 7 is centrifuged, the bottom flow 16 of the secondary cyclone flows to the desulfurization tower 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com