Waterproof shock-absorption road surface structure and construction method thereof

A technology of pavement structure and waterproof layer, which is applied in the direction of roads, roads, on-site paved condensate pavements, etc., and can solve the problems of insufficient vibration resistance of surface materials and base materials, frost heave damage of pavement structures, low cycle fatigue damage, etc. problems, to achieve the effect of reducing road surface subsidence, solving groundwater damage, and reducing tangential constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

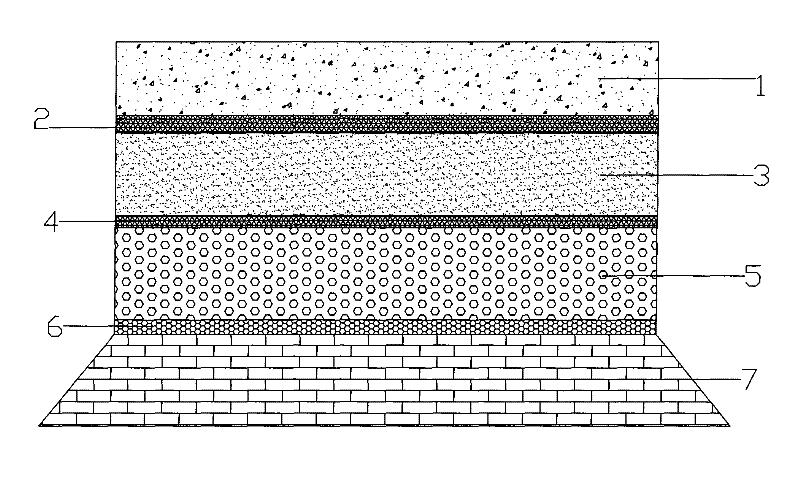

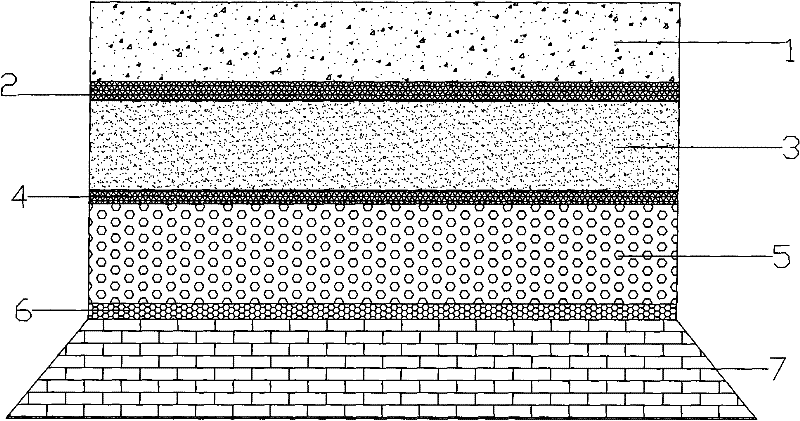

[0020] Embodiment 1, the surface layer 1 is an ordinary cement concrete surface layer, the waterproof and vibration-damping functional layer 2 is a composite plastic woven cloth with a thickness of 0.2 mm, the base layer 3 is a semi-rigid base layer, and the waterproof layer 4 is a waterproof geomembrane with a thickness of 0.1 mm The drainage cushion 5 is an organic binder stabilized granular cushion, and the permeable filter layer 6 is a permeable filter geotextile with a thickness of 0.5 mm. The waterproof and vibration-damping pavement structure of the present invention can be paved according to the aforementioned construction method.

Embodiment 2

[0021] Embodiment 2, the surface layer 1 is an asphalt concrete composite surface layer, the waterproof and vibration-damping functional layer 2 is a waterproof geomembrane with a thickness of 1.0mm, the base layer 3 is a flexible base layer, the waterproof layer 4 is a plastic film with a thickness of 0.5mm, and the drainage pad Layer 5 is an inorganic binder stabilized granular material cushion, and water-permeable filter layer 6 is a water-permeable filter geotextile layer with a thickness of 1.25 mm. The waterproof and vibration-damping pavement structure of the present invention can be paved according to the aforementioned construction method.

Embodiment 3

[0022] Embodiment 3, the surface layer 1 is a fiber concrete surface layer, the waterproof and vibration-damping functional layer 2 is a plastic film with a thickness of 0.6 mm, the base layer 3 is a flexible base layer, the waterproof layer 4 is a waterproof geomembrane with a thickness of 0.3 mm, and the drainage cushion 5 is a granular material cushion, and the water-permeable filter layer 6 is a water-permeable filter geotextile layer with a thickness of 2mm. The waterproof and vibration-damping pavement structure of the present invention can be paved according to the aforementioned construction method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com