ABO3/TiO2/MgO/III-V group nitride semiconductor heterostructure and preparation method

A nitride semiconductor, heterostructure technology, applied in the field of microelectronic materials, to achieve the effect of reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

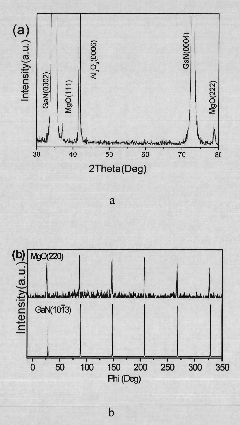

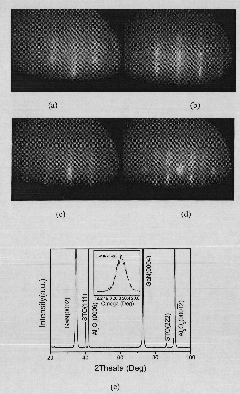

[0040] Such as Figure 8 , the ABO of this example 3 / TiO 2 / MgO / hexagonal III-nitride semiconductor heterostructure has three layers, on the semiconductor substrate and ABO 3 Between the oxide film functional layers, there is a MgO barrier layer and TiO 2 Composite buffer layer composed of template layer.

[0041] The hexagonal III-V nitride semiconductor is oriented in the (0001) direction. The MgO barrier layer is oriented along the (111) direction, and the TiO 2 The template layer is oriented along the (200) direction, while the ABO 3 The functional oxide film is oriented along the (111) direction. ABOs 3 In the metal oxide, A is an element among Mg, Ca, Sr, Ba, Pb, Bi, and La, and B is an element among Ti, Zr, Fe, Ru, and Ni.

Embodiment 2

[0043] The difference between this example and Example 1 is that A is a solid solution composed of two or more elements in Mg, Ca, Sr, Ba, Pb, Bi, La, and B is Ti, Zr, Fe, Ru, Ni A solid solution composed of two or more elements in , and, based on the molar ratio of A element, B element and oxygen element, the stoichiometric ratio satisfies (A 1 +A 2 +......+An): (B 1 +B 2 +...+Bn):O=1:1:3.

[0044] ABOs 3 Metal oxides can be doped with a certain proportion of modified oxides, namely RE A oxide or RE B oxides, the stoichiometric ratio satisfies (A 1 +A 2 +......+An+RE A ): (B 1 +B 2 +......+Bn+RE B ):O=1:1:3, where RE A and RE B Each represents an element in La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Y, Mn.

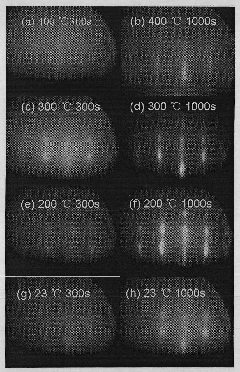

[0045] As an embodiment of the preparation method, using laser molecular beam epitaxy (L-MBE), using GaN / Al 2 o 3 and AlGaN / GaN / Al 2 o 3 Epitaxial wafer and MgO, TiO 2 and STO ceramic target, MgO barrier layer, TiO 2 Template layers an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com