Scandium oxide-stabilizing zirconia powder and preparation method thereof

A technology for stabilizing zirconia and scandium oxide, which is applied in zirconia and other directions, can solve the unsolved problems of compatibility between conductivity and strength indicators, the lack of low-cost processes and methods, hard agglomeration of powders and uneven doping, etc. Achieve the effect of taking into account the high strength index of conductivity, low cost and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

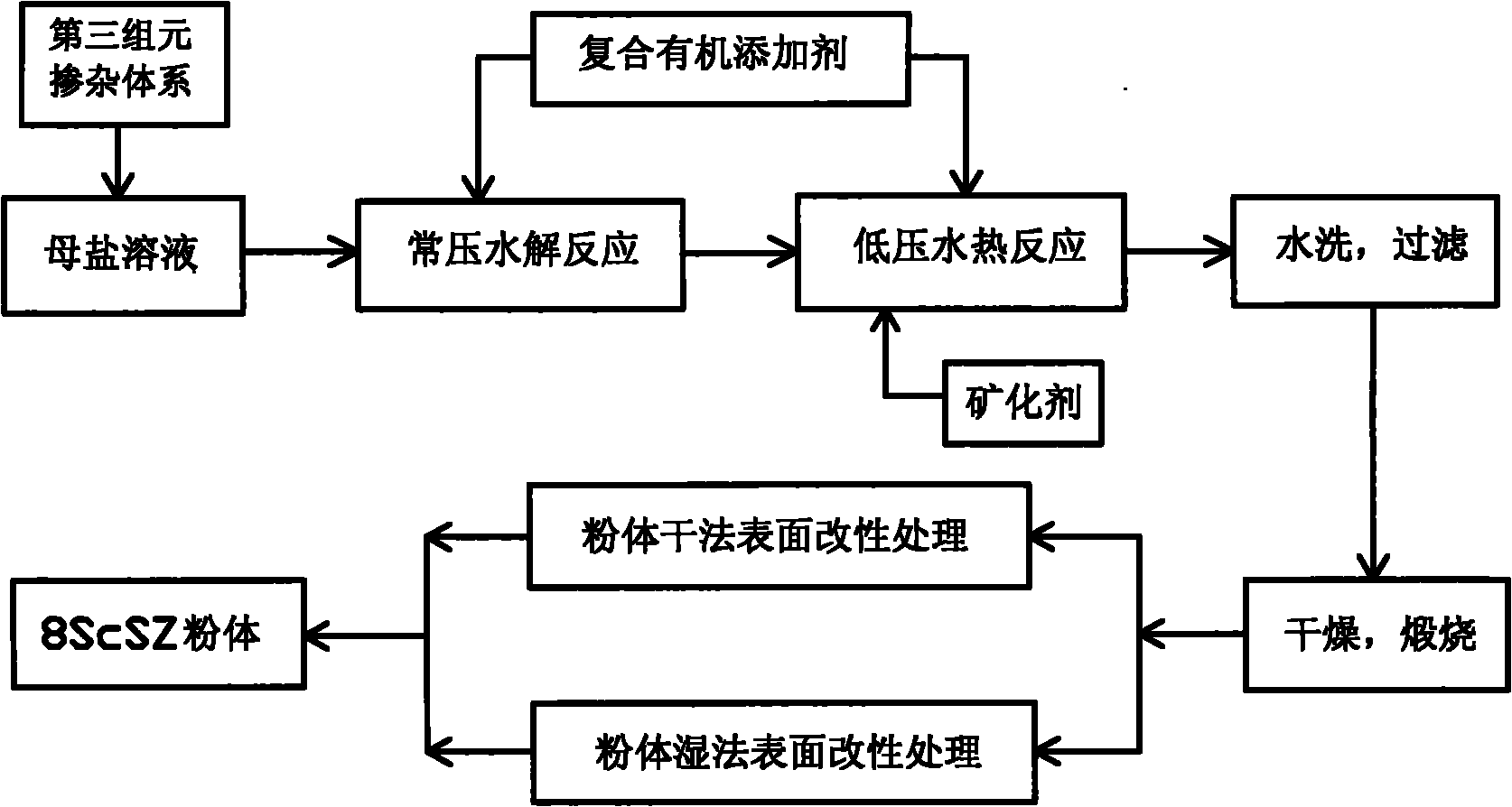

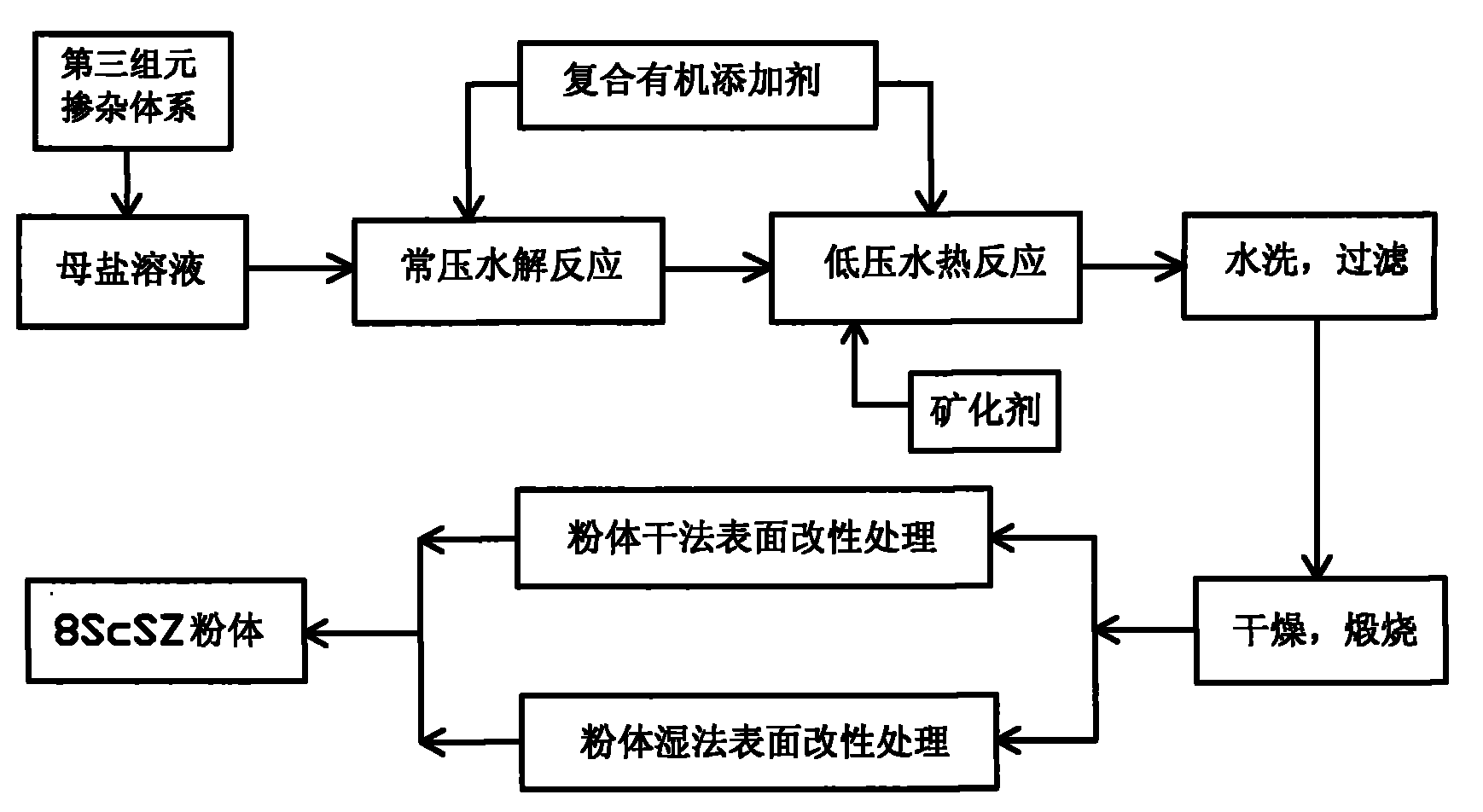

Method used

Image

Examples

Embodiment 1

[0034] In the pre-designed reaction kettle, prepare a certain concentration of precursor mother salt zirconium oxychloride solution, add scandium oxide according to the ratio of 8mol%, heat and stir to dissolve, and then heat the prepared solution for a long time After a period of time, add a mineralizer and heat water, and finally wash with water, filter with suction, dry and calcinate to obtain the powder of the present invention.

Embodiment 2

[0036] In the pre-designed reaction kettle, prepare a certain concentration of precursor mother salt zirconium oxychloride solution, add scandium oxide according to the proportion of 8mol%, and add cerium oxide according to the proportion of 0.5wt%, and other conditions are the same as in the embodiment 1.

Embodiment 3

[0038] Replace "0.5wt% cerium oxide" with "0.5wt% aluminum oxide" in Example 2, and the rest of the conditions are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com