High-strength composite material for caulking, repair and water prevention of concrete/inorganic plate and preparation method thereof

A composite material and concrete technology, which is applied in the field of composite materials and its preparation, can solve the problems of reducing the durability of concrete, water seepage performance, hollowing of the pasting surface, etc., and achieves the improvement of workability, water reduction and workability, and good construction easiness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

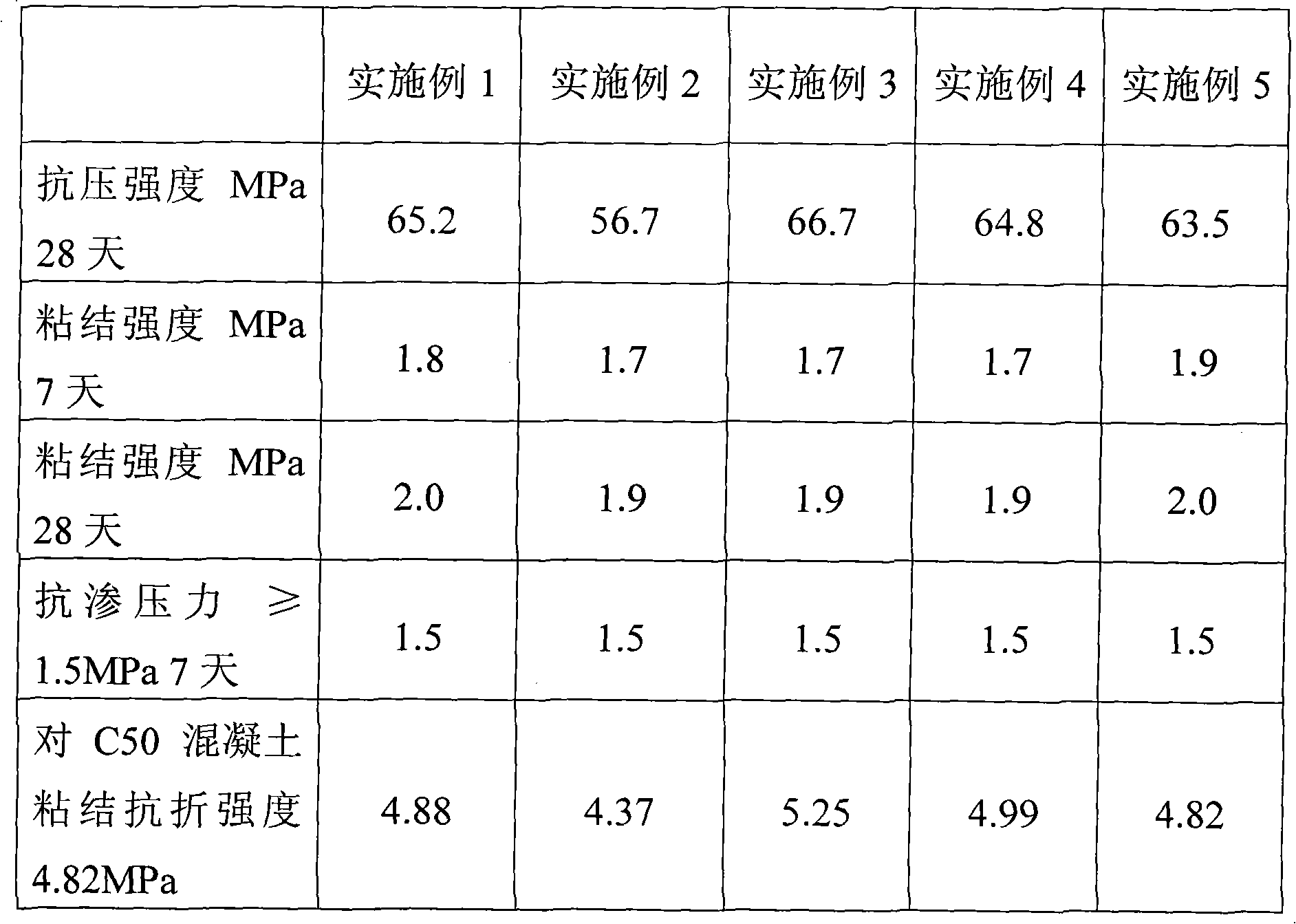

Embodiment 1

[0049] Cement dry-mixed mortar, the ratio of parts by mass is:

[0050] Cement P.O.42.5 100

[0051] Fine sand 120 (fineness modulus 1.7)

[0052] Medium sand 130 (fineness modulus 3.0)

[0053] Medium-effect superplasticizer lignosulfonate 3

[0054] Mix the cement dry-mixed mortar in the powder mixer according to the formula ratio, stir evenly, and pack it for later use;

[0055] Modified polymer emulsion, the ratio of parts by mass is:

[0056] Styrene acrylic emulsion 10

[0057] water 5

[0058] Defoamer BT-1022 type 0.3

[0059] Disperse the modified polymer emulsion evenly in a liquid disperser according to the formula ratio, and pack it for later use.

[0060] Instructions:

[0061] On the construction site, mix cement dry-mixed mortar and modified polymer emulsion at a ratio of 10:1, use mechanical stirring (about 5 minutes to 20 minutes), and directly chop and scrape the construction site.

[0062] After construction, the normal environment can bear the load...

Embodiment 2

[0071] Cement dry-mixed mortar, the ratio of parts by mass is:

[0072] Cement P.O.42.5 100

[0073] Fine sand 180 (fineness modulus 1.7)

[0074] Medium sand 70 (fineness modulus 3.0)

[0075] Medium-effect superplasticizer lignosulfonate 3

[0076] Mix the cement dry-mixed mortar in the powder mixer according to the formula ratio, stir evenly, and pack it for later use;

[0077] Modified polymer emulsion, the ratio of parts by mass is:

[0078] Pure acrylic emulsion 11

[0079] water 4

[0080] Defoamer BT-1022 type 0.3

[0081] Disperse the modified polymer emulsion evenly in a liquid disperser according to the formula ratio, and pack it for later use.

[0082] Instructions:

[0083] On the construction site, mix cement dry-mixed mortar and modified polymer emulsion at a ratio of 10:1, use mechanical stirring (about 5 minutes to 20 minutes), and directly chop and scrape the construction site.

[0084] After construction, the normal environment can bear the load aft...

Embodiment 3

[0093] Cement dry-mixed mortar, the ratio of parts by mass is:

[0094] Cement P.O 42.5 100

[0095] Fine sand 100 (fineness modulus 1.7)

[0096] Medium sand 150 (fineness modulus 3.0)

[0097] Medium-effect superplasticizer lignosulfonate 3

[0098] Mix the cement dry-mixed mortar in the powder mixer according to the formula ratio, stir evenly, and pack it for later use;

[0099] Modified polymer emulsion, the ratio of parts by mass is:

[0101] water 7

[0102] Defoamer BT-1022 type 0.3

[0103] Disperse the modified polymer emulsion evenly in a liquid disperser according to the formula ratio, and pack it for later use.

[0104] Instructions:

[0105] On the construction site, mix cement dry-mixed mortar and modified polymer emulsion at a ratio of 10:1, use mechanical stirring (about 5 minutes to 20 minutes), and directly chop and scrape the construction site.

[0106] After construction, the normal environment can bear the load after 3 d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com