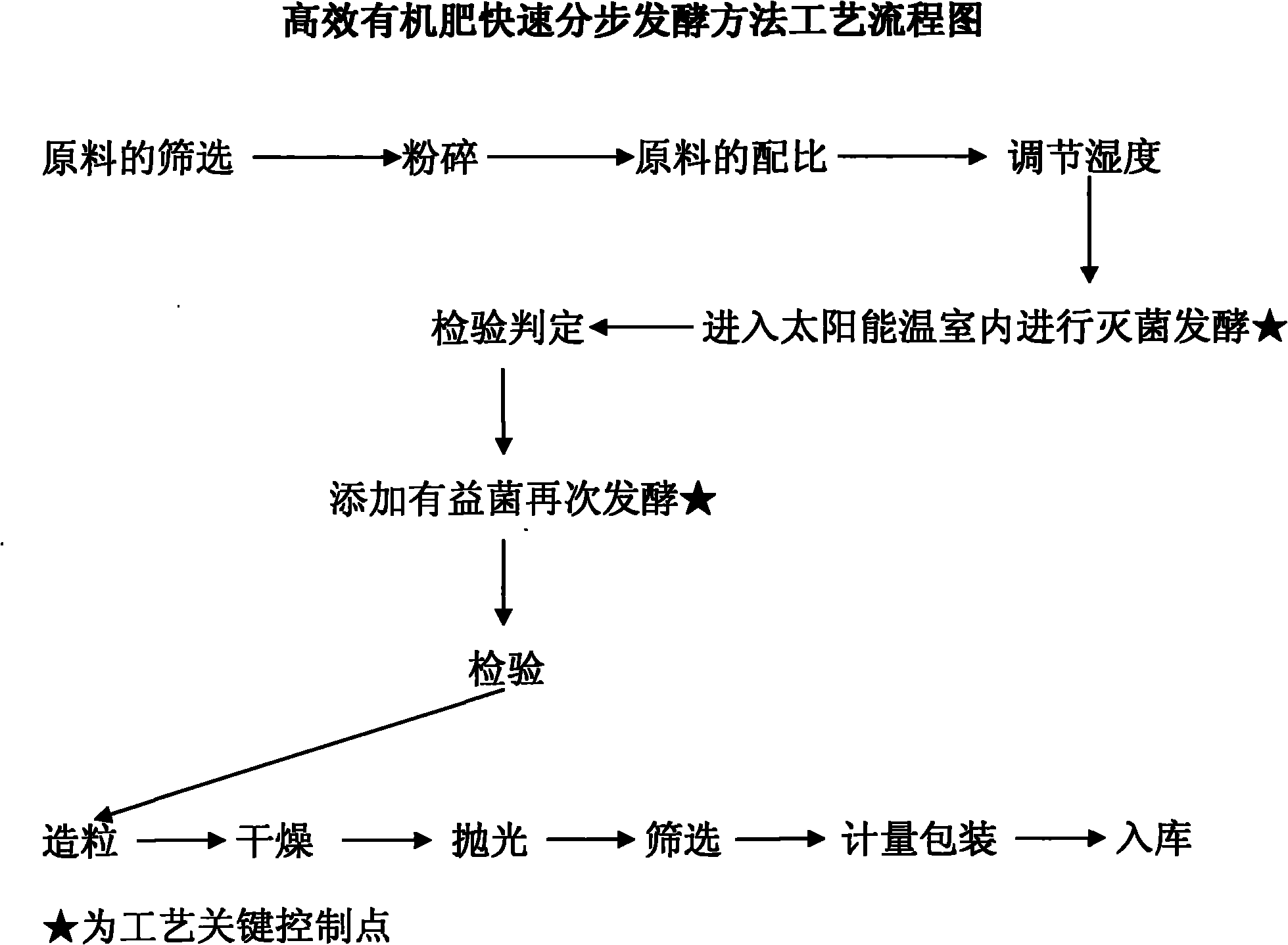

Efficient, fast and fractional fermentation method of organic fertilizer

A step-by-step fermentation and organic fertilizer technology, applied in the direction of organic fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve problems such as imbalance of nutrient element ratio, decline of fertility supply capacity, large amount of smoke and dust emitted by boilers, etc., and reach the fermentation period short, improve geology, and strengthen the effect of water source protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparations

[0031] ①Screen feces, straw and other raw materials first, remove impurities and pulverize them for later use;

[0032] ② Water should be used to adjust the humidity of the dried manure, so that it can be held into a ball and loosened when loosened. The fresher the manure, the better;

[0033] ③ Soak the stalks to be fermented with manure in advance. It is best to use crushed stalks, the shorter the stalks, the faster the rotting and the better the rotting effect;

[0034] ④ Raw material feeding ratio per ton: by weight percentage, 80% of livestock manure, 20% of straw, 2 kg / ton of Bacillus lateralis;

[0035] The bacterial species is Bacillus lateralis, belonging to the genus Bacillus, Gram staining is positive and can be negative, the spores are oval, lateral, mesogenic or near mesogenic, the cysts are enlarged, and the free spores are thicker on one side than the other (canoe shape);

[0036] Bacillus lateralis is a natural strain approved by t...

Embodiment 2

[0048] 1. Preparations

[0049] ①Screen feces, straw and other raw materials first, remove impurities and pulverize them for later use;

[0050] ② Water should be used to adjust the humidity of the dried manure, so that it can be held into a ball and loosened when loosened. The fresher the manure, the better;

[0051] ③ Soak the stalks to be fermented with manure in advance. It is best to use crushed stalks, the shorter the stalks, the faster the rotting and the better the rotting effect;

[0052]④ Raw material input ratio per ton: by weight percentage, 85% of livestock manure, 15% of straw, 3 kg / ton of Bacillus lateralis;

[0053] The bacterial species is Bacillus lateralis, belonging to the genus Bacillus, Gram staining is positive and can be negative, the spores are oval, lateral, mesogenic or near mesogenic, the cysts are enlarged, and the free spores are thicker on one side than the other (canoe shape);

[0054] Bacillus lateralis is a natural strain approved by the ...

Embodiment 3

[0066] 1. Preparations

[0067] ①Screen feces, straw and other raw materials first, remove impurities and pulverize them for later use;

[0068] ② Water should be used to adjust the humidity of the dried manure, so that it can be held into a ball and loosened when loosened. The fresher the manure, the better;

[0069] ③ Soak the stalks to be fermented with manure in advance. It is best to use crushed stalks, the shorter the stalks, the faster the rotting and the better the rotting effect;

[0070] ④ Raw material input ratio per ton: by weight percentage, livestock manure 82% straw 18%, Bacillus lateralis 2.5 kg / ton;

[0071] The bacterial species is Bacillus lateralis, belonging to the genus Bacillus, Gram staining is positive and can be negative, the spores are oval, lateral, mesogenic or near mesogenic, the cysts are enlarged, and the free spores are thicker on one side than the other (canoe shape);

[0072] Bacillus lateralis is a natural strain approved by the Microbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com