Hollow microsphere thermal insulation coating and production method thereof

A technology of thermal insulation and production method, which is applied in the direction of coating, etc., to achieve the effect of overcoming easy aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

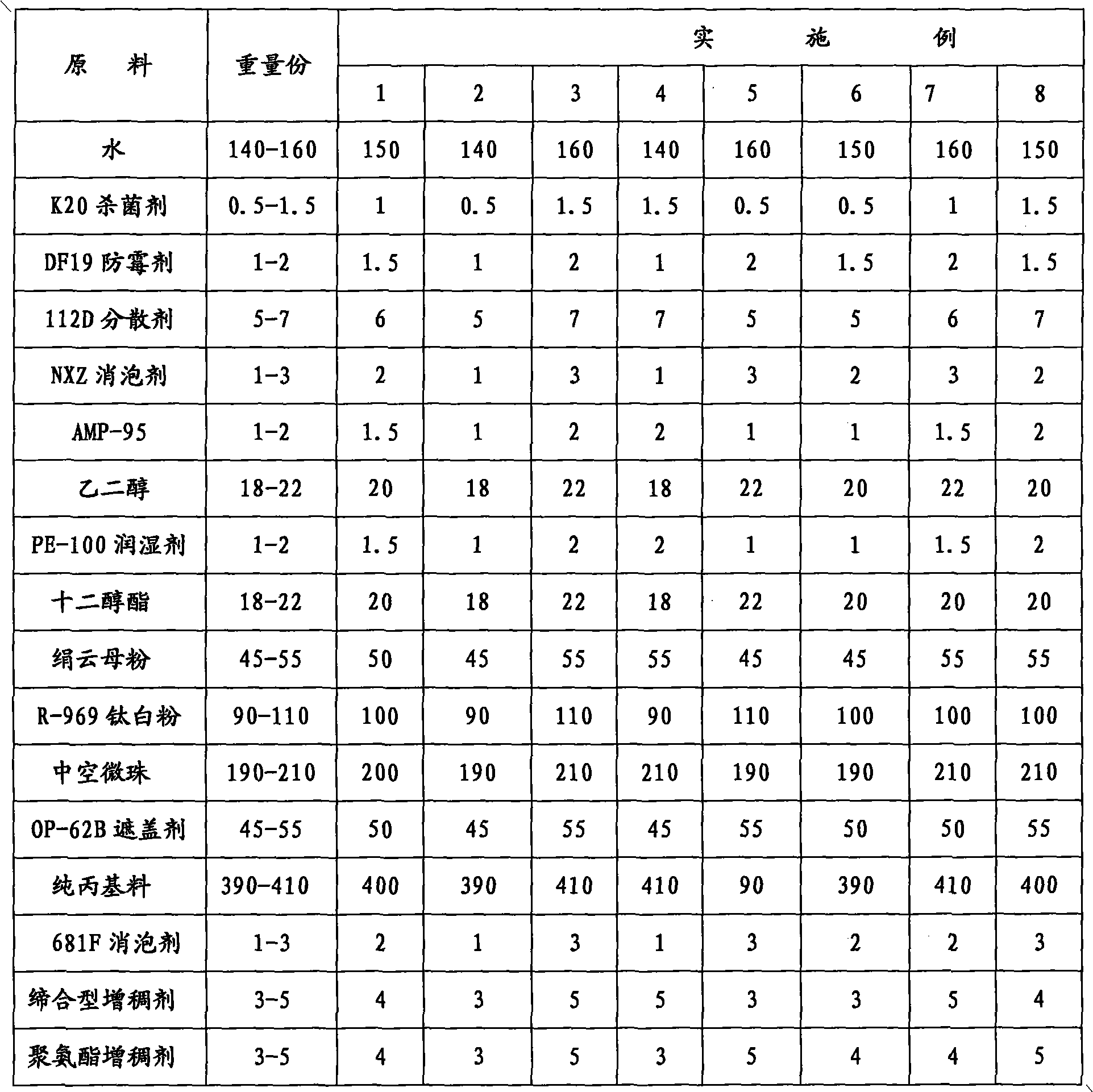

Examples

Embodiment 1

[0015] Example 1 (compare the corresponding raw materials and parts by weight of Example 1 in the above table): First, 150 parts of water, 6 parts of 112D dispersant, 2 parts of NXZ defoamer, 100 parts of R-969 titanium dioxide, 50 parts of silk Mica powder and 4 parts of associative thickener are sequentially added to the dispersing cylinder of the disperser and stirred at a speed of (300-400)r / min, pre-mixed for 5-10min; then increase the speed to (1200-1500)r / Disperse at high speed for 20-30 minutes, disperse pigments and fillers into primary particles, first add 2.5 parts of polyurethane thickener in 4 parts, and then adjust the speed to (900-1100)r / min for 5-8min; then First add about 240 parts of pure propyl material in 400 parts, then slowly add 200 parts of hollow glass beads, continue to (900-1100) r / min speed dispersion for 10-15 minutes; finally carry out paint mixing, add the remaining 160 Parts of pure propyl material, 2 parts of 681F defoamer, 1.5 parts of AMP-95...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com