Hydrogen refueling station hydrogen optimizing filling method based on temperature rise and energy consumption control and system thereof

A filling system and control system technology, which is applied in the field of hydrogen optimal filling method with high gas extraction rate and its optimized operation system, and can solve problems such as high gas extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

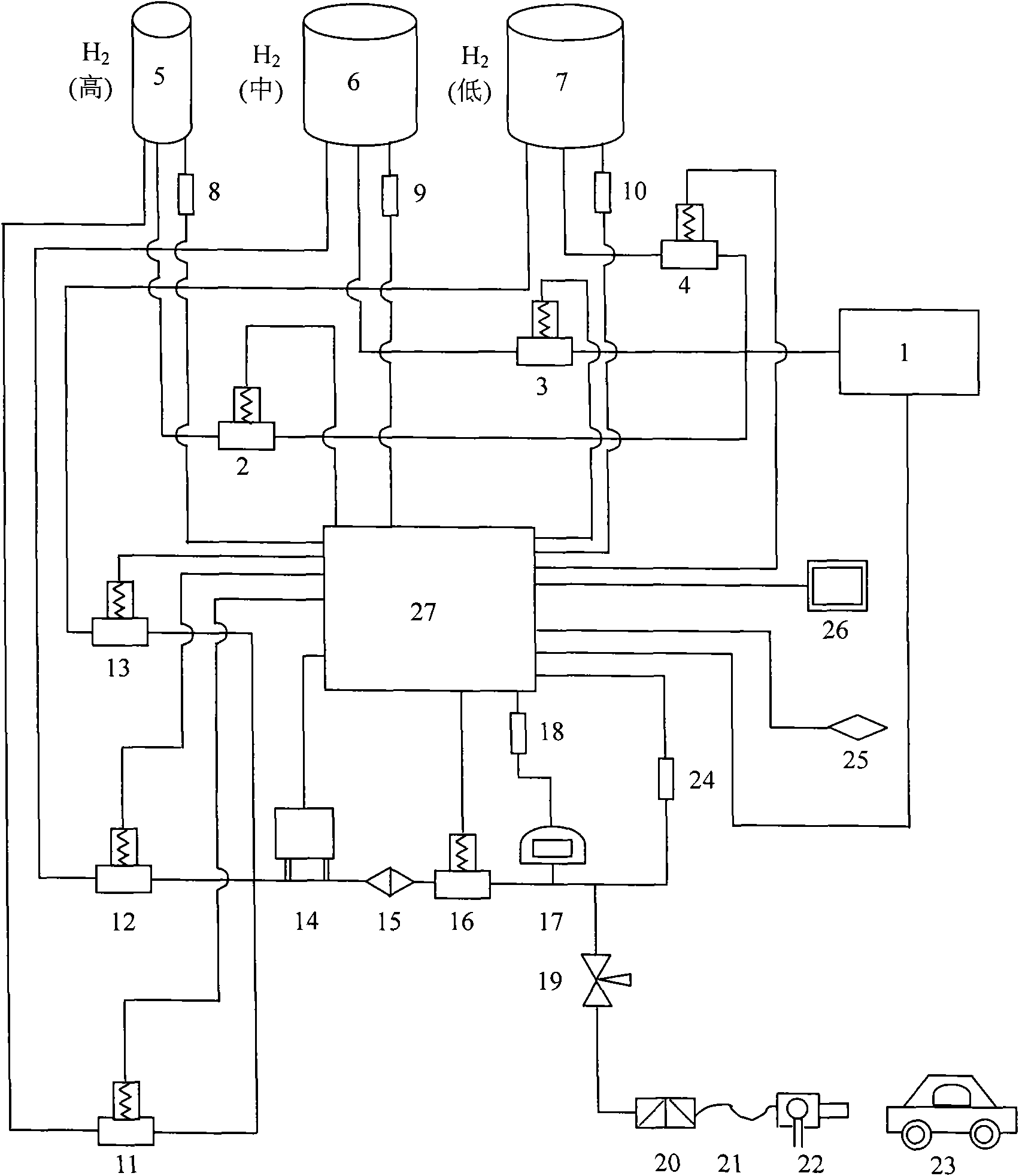

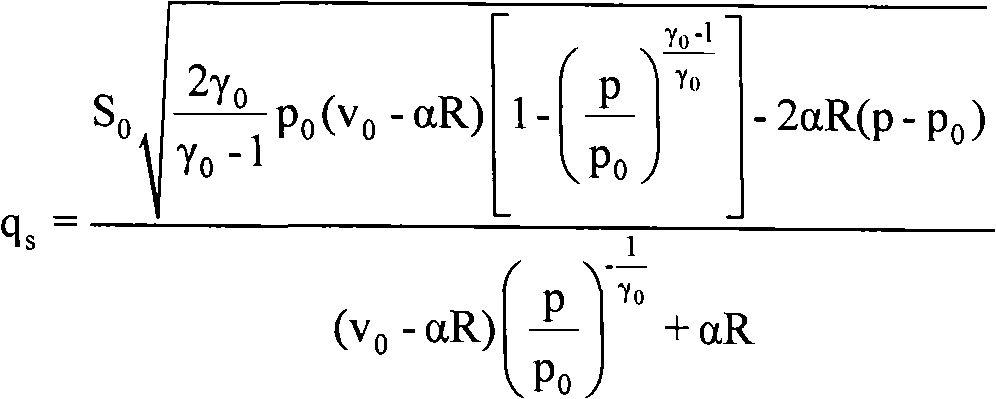

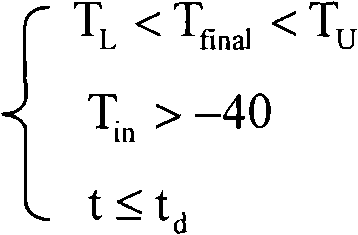

[0071] Optimum control of temperature rise and filling rate: When filling high-pressure hydrogen for the fuel cell vehicle 23, the programmable controller 27 receives the vehicle-mounted hydrogen storage container model information, initial temperature and pressure signals, and temperature sensor 24 from the communication interface 25. The measured ambient temperature and the pressure of the fixed hydrogen storage tank of the hydrogen refueling station measured by the pressure sensors 8-10 are queried in the optimization results pre-stored in the programmable controller 27 to obtain hydrogen storage levels from low, medium and high pressure levels respectively. The opening value of the needle valve 19 when the tanks 5-7 take air, and the corresponding operation of the cooling device 14. Since the optimal control is based on the calculation formula of temperature rise, the calculation of filling time and the mathematical optimization model of multi-stage high-pressure hydrogen f...

Embodiment 2

[0081] Sequential gas intake control: When the filling rate is used as the switching condition during the filling process, the programmable controller 27 will give priority to sending a control signal, open the solenoid valve 13, and take gas from the low-pressure hydrogen storage tank 7. During the filling process, according to the communication interface The pressure signal at 25 is used to determine whether the vehicle-mounted hydrogen storage container has reached the specified filling pressure. At the same time, it is determined whether the mass flowmeter 17 and the flow transmitter 18 are sent to the programmable controller 27 at the current moment and the accumulated mass at the previous moment. Whether the flow difference reaches the set value, when the measured pressure of the on-board hydrogen storage container reaches the specified filling pressure, and the quality difference between the current moment and the last moment has not reached the set value, stop filling N...

Embodiment 3

[0083] Sequential gas supply control: the programmable controller 27 judges whether the pressures of the high, medium and low pressure hydrogen storage containers 5 to 7 measured by the pressure sensors 8 to 10 have dropped to the pressure setting for starting the gas supply in the optimization result value, when the set gas supply pressure is reached, the compressor unit 1 will be started, and the solenoid valves 2 to 4 will be opened or closed according to the priority order of high-middle-low to complete the maintenance of the hydrogen refueling station. Sequential refilling of stationary hydrogen tank systems. While ensuring fast, effective, safe and reliable gas extraction, and having the highest gas extraction rate of the hydrogen storage tank, the entire compressor unit 1 always operates with the lowest energy consumption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com