Evaporation equipment

A technology of evaporation equipment and evaporation source, which is applied in the direction of vacuum evaporation plating, ion implantation plating, metal material coating technology, etc., which can solve the problems of poor uniformity of film formation, increased area of glass substrate, and difficult realization Large area and other problems, to achieve the effect of uniform coating on a large area, improve utilization rate, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

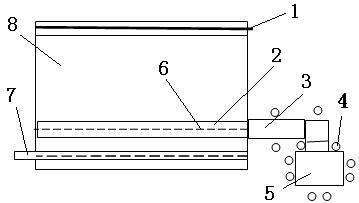

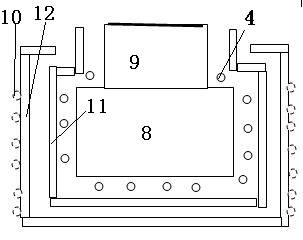

[0025] Specific embodiments of the present invention, such as figure 1 with figure 2 As shown, an evaporation device includes:

[0026] (A) An evaporation source 5, which can heat the source material to vaporize to produce source material vapor;

[0027] (B) A box 8 connected to the evaporation source 5 through a conduit 3, the box 8 has a linear outlet 1, and the linear outlet 1 guides the vapor in the box 8 to flow to the substrate;

[0028] (C) The heating component 4 that prevents material from being deposited on the inner wall of the box 8;

[0029] (D) Two-layer shells 11, 12 and cooling pipes 10 distributed around the box 8 and the evaporation source 5.

[0030] In the above embodiment, the shell can be a layer; inside the box 8 there is a pipe 2 connected to the evaporation source 5, and holes 6 are distributed on the pipe 2 to make the vapor uniformly distributed in the slit direction of the linear outlet 1, where the holes 6 does not point to the direction of the linear ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com