Nonmetal ceramic matrix drum brake pad for bus and preparation method thereof

A non-metallic and brake pad technology, applied in the field of non-metal ceramic based drum brake pads and its preparation, can solve the problems of affecting the stability of braking force, reducing the friction coefficient, frequent braking, etc., and achieves simple and feasible preparation method, emergency braking Sensitive movement and good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Tin Sulfide 30, Aramid Fiber 2,

[0030] mineral fiber 28, carbon fiber 3,

[0031] Fiberglass 3, Brass Fiber 5,

[0032] Chromite 4, Artificial Graphite 4,

[0033] flake graphite 8, friction powder 4,

[0034] rubber 2, compound filler 5,

[0035] Calcium carbonate powder 2.

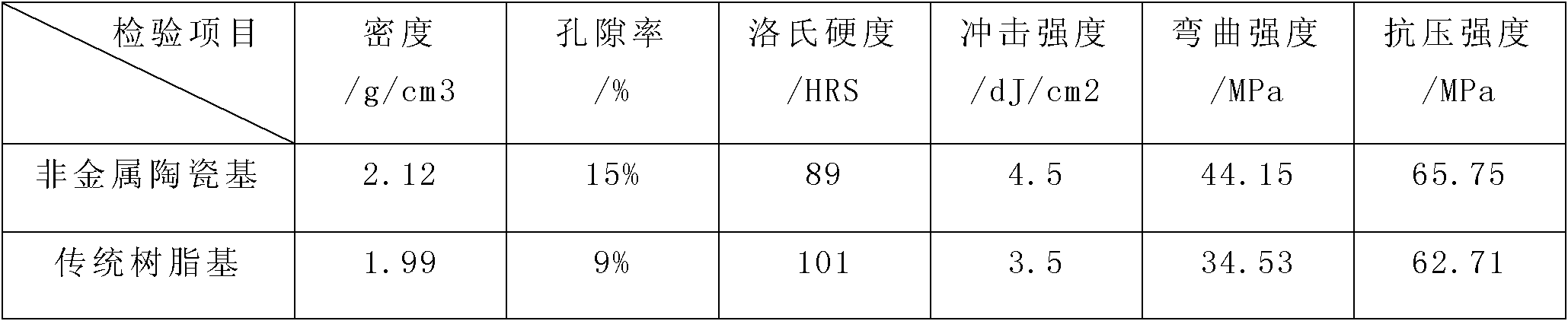

[0036] In this formula system, the ceramic binder is mainly an inorganic high-temperature binder such as metal sulfide, which can significantly improve the temperature resistance of the material, reduce the wear of the material at high temperature, and make the material form a network porous structure. Increased braking smoothness and reduced braking noise. In order to continue to use the molding process and production equipment of resin-based automobile brake pads, a small amount of resin and rubber is added to reduce equipment investment and production costs.

[0037] Composite fiber has excellent dispersibility and adsorption, especially, it has excellent affinity with resin, friction m...

Embodiment 2

[0057] Tin sulfide 20, Aramid fiber 3,

[0058] mineral fiber 27, carbon fiber 2,

[0059] Fiberglass 2, Brass Fiber 5,

[0060] Chromite 4, Artificial Graphite 7,

[0061] flake graphite 14, friction powder 8,

[0062] rubber 4, compound filler 10,

[0063] Calcium carbonate powder 4.

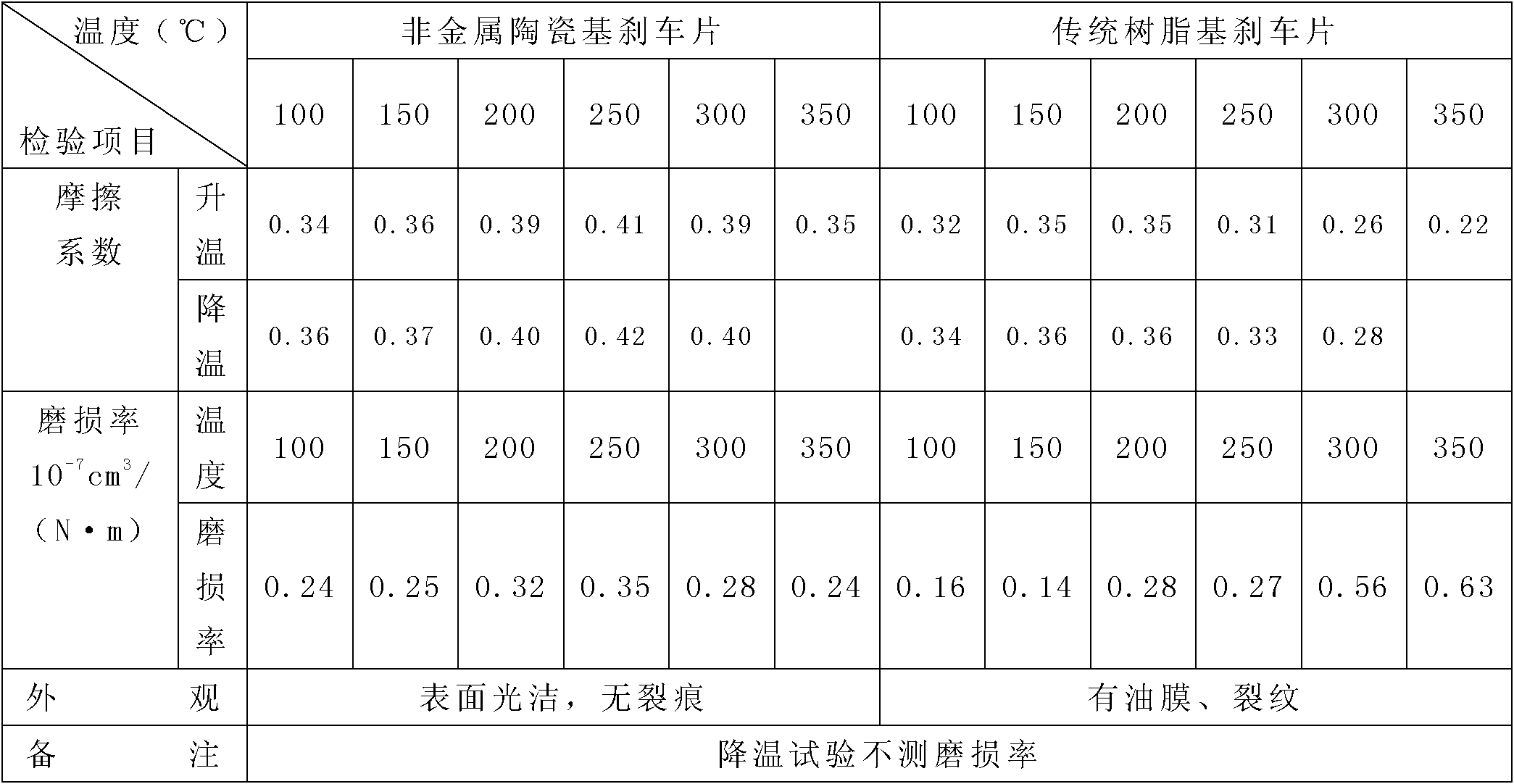

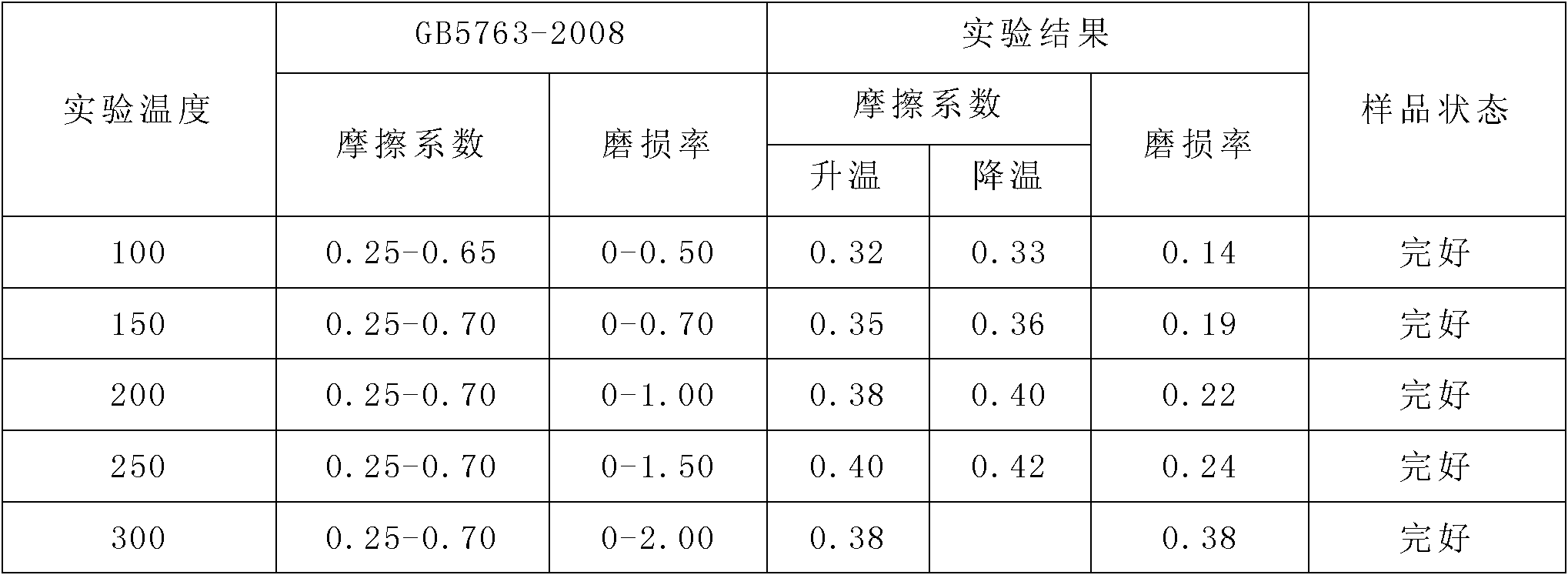

[0064] The preparation method of embodiment 2 is the same as that of embodiment 1, and table 3 is the constant speed test result of the brake pad prepared by embodiment 2:

[0065] The constant speed experiment result of table 3 embodiment 2 brake pads

[0066]

Embodiment 3

[0068] Tin Sulfide 20, Aramid Fiber 1,

[0069] mineral fiber 29, carbon fiber 3,

[0070] Fiberglass 3, Brass Fiber 5,

[0071] Chromite 2, Artificial Graphite 5,

[0072] flake graphite 10, friction powder 10,

[0073] rubber 5, compound filler 5,

[0074] Calcium carbonate powder 2.

[0075] The preparation method of embodiment 3 is the same as that of embodiment 1, and table 4 is the constant speed test result of the brake pad prepared by embodiment 3:

[0076] The constant speed test result of table 4 embodiment 3 brake pads

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com