Heat pump water heater

A heat pump water heater and water heater technology, which is applied to heat pumps, water heaters, indirect heat exchangers, etc., can solve the problems of lower heating capacity and energy efficiency ratio of heat pumps, lower heat exchange capacity of condensers, and high consumption of heat exchanger materials. Achieve the effect of improving market competitiveness, improving heat exchange capacity, simple and practical structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

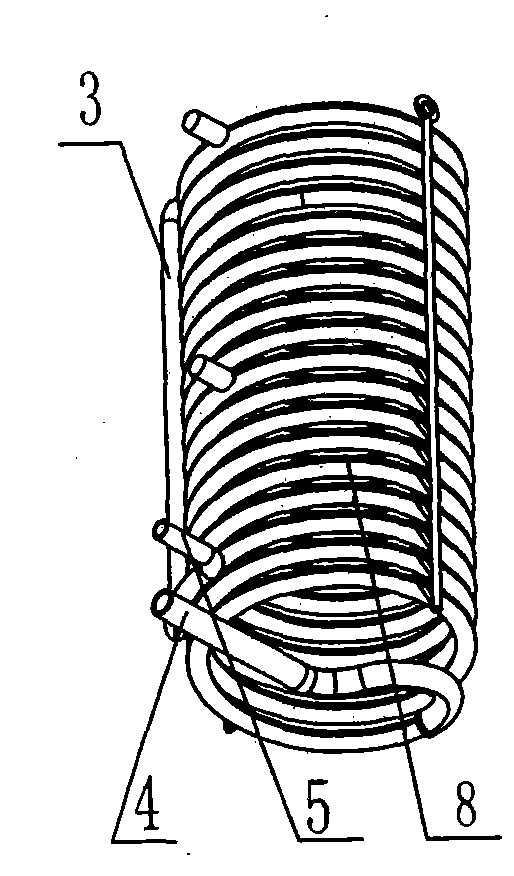

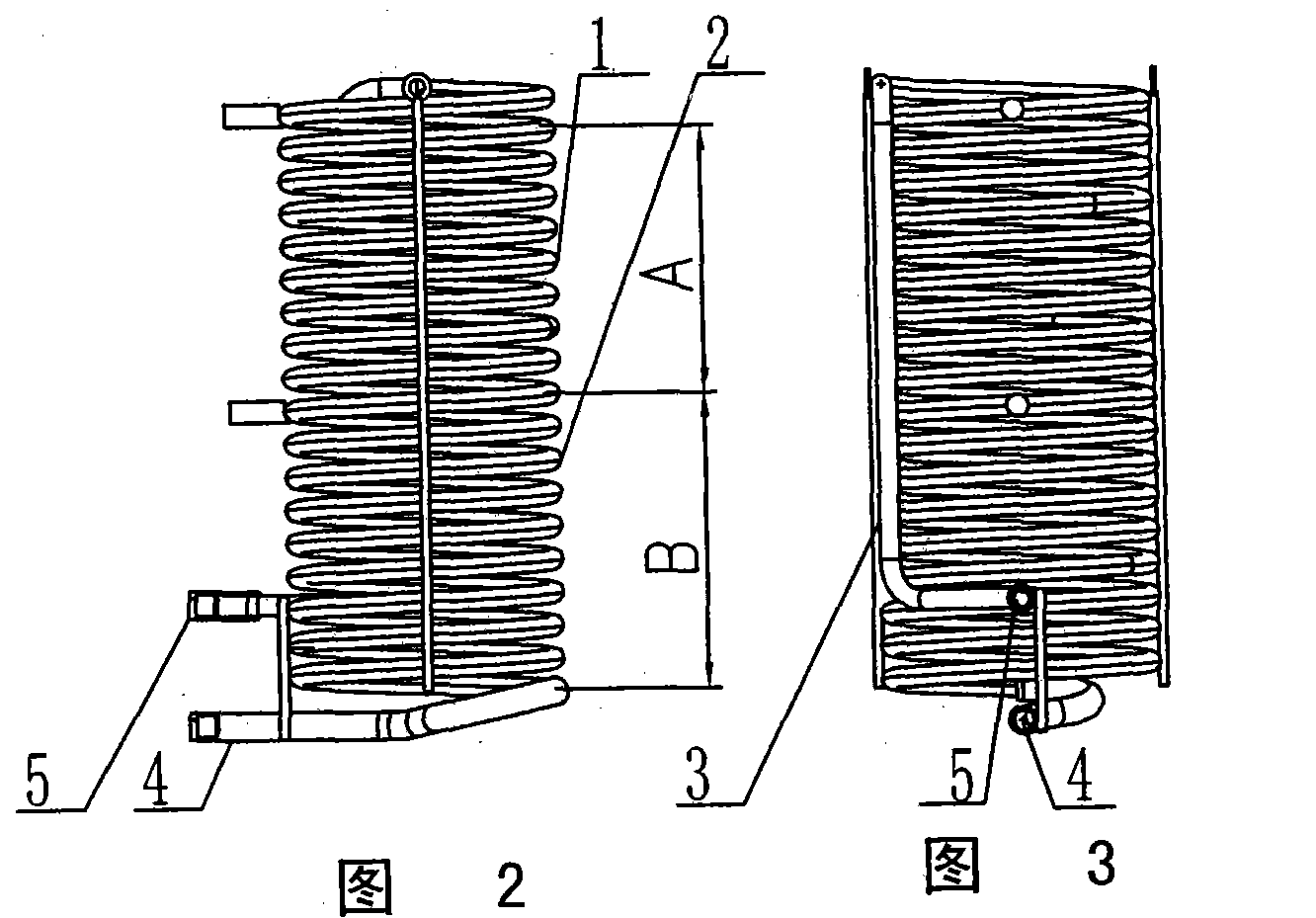

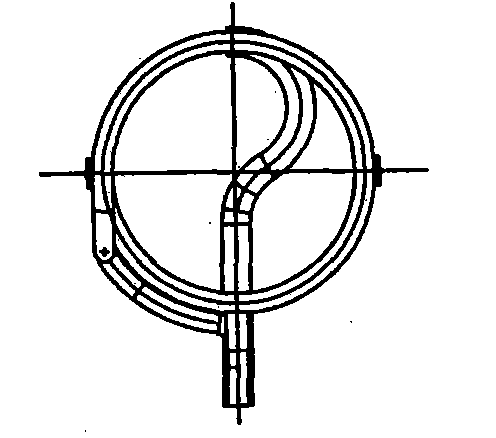

[0020] The structure of the heat pump water heater of the present embodiment is as follows: Figure 5 As shown, it is a preferred embodiment of the invention: a small household heat pump water heater includes a heat pump system composed of a compressor, a variable diameter condenser, a throttling element, and an evaporator. Among them, the variable-diameter condenser composed of the front section heat exchange tube 1 and the rear section heat exchange tube 2 connected in series - the variable-diameter coil tube 8 is built in the hot water storage tank 9 (the condenser adopts single-way heat exchange instead of multi-way split flow), Among them, the inner diameter of the latter stage coil is smaller than that of the former stage, and the length is equivalent to that of the former stage.

[0021] When working, the refrigerant of the heat pump system enters the front heat exchange tube 1 from the refrigerant steam inlet 4, and flows out from the intake connecting pipe 3 outside t...

Embodiment 2

[0027] Another embodiment of the present invention is Image 6 As shown, the condensing and heat-exchanging coil 8 is wound around the outer wall of the inner tank 11 of the water tank 9 and is located in the insulation layer, so as to perform indirect heat exchange with the water in the inner tank, and the whole is kept insulated by the insulation layer.

[0028] Experiments have proved that after adopting this embodiment, the heat exchange capacity of the condensing side is also significantly improved, and the required heat exchange area is effectively reduced, thereby significantly saving materials and reducing manufacturing costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com