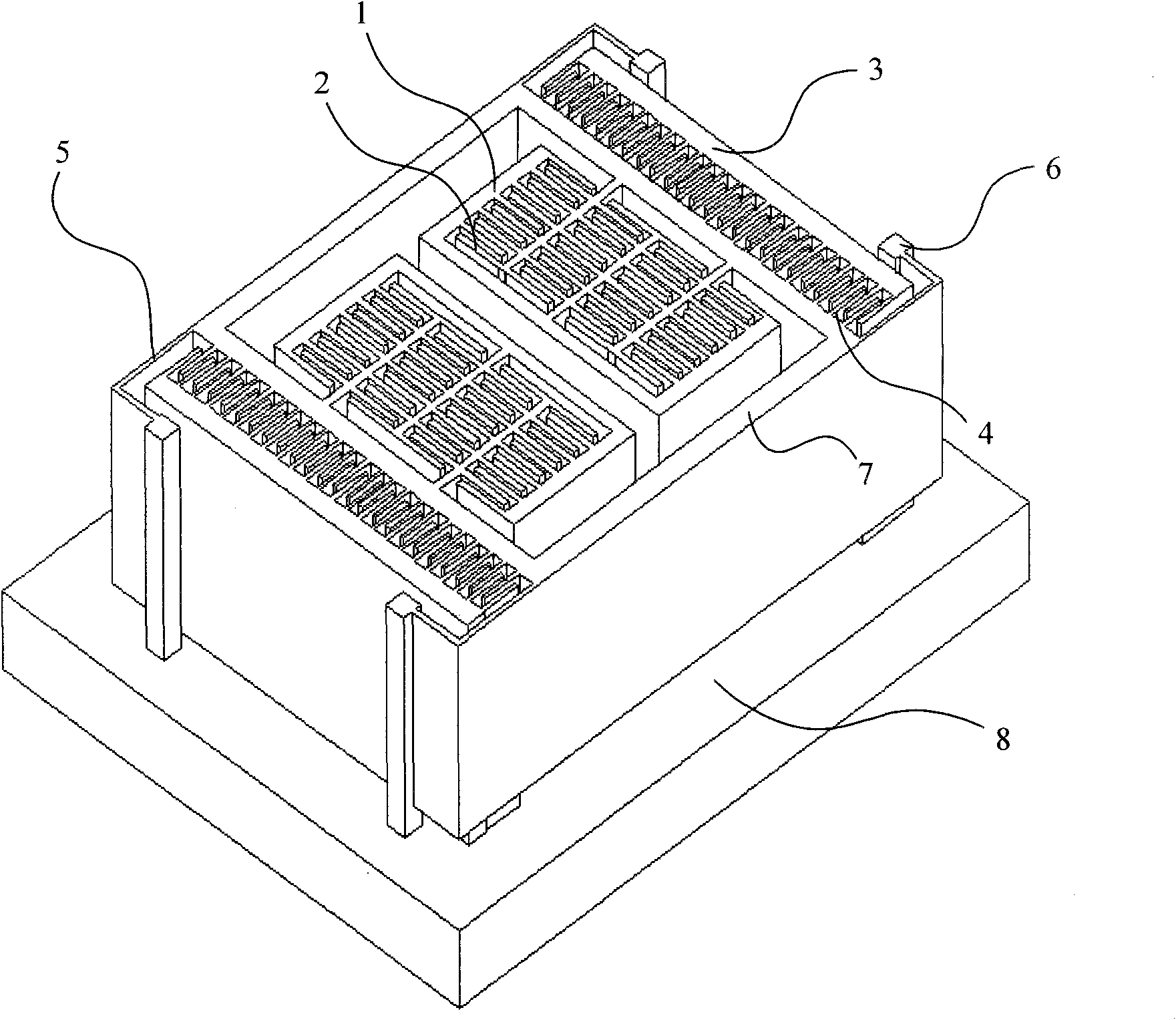

Frame-type variable capacitor and preparation method thereof

A variable capacitance, frame-type technology, applied to variable capacitors, capacitors that change capacitance mechanically, capacitors, etc., can solve the problem of not improving the Q value, variable capacitance ratio variable capacitors, and performance parameters that cannot meet the design Value, process difficulty and other issues, to achieve the effect of high yield and reliability, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

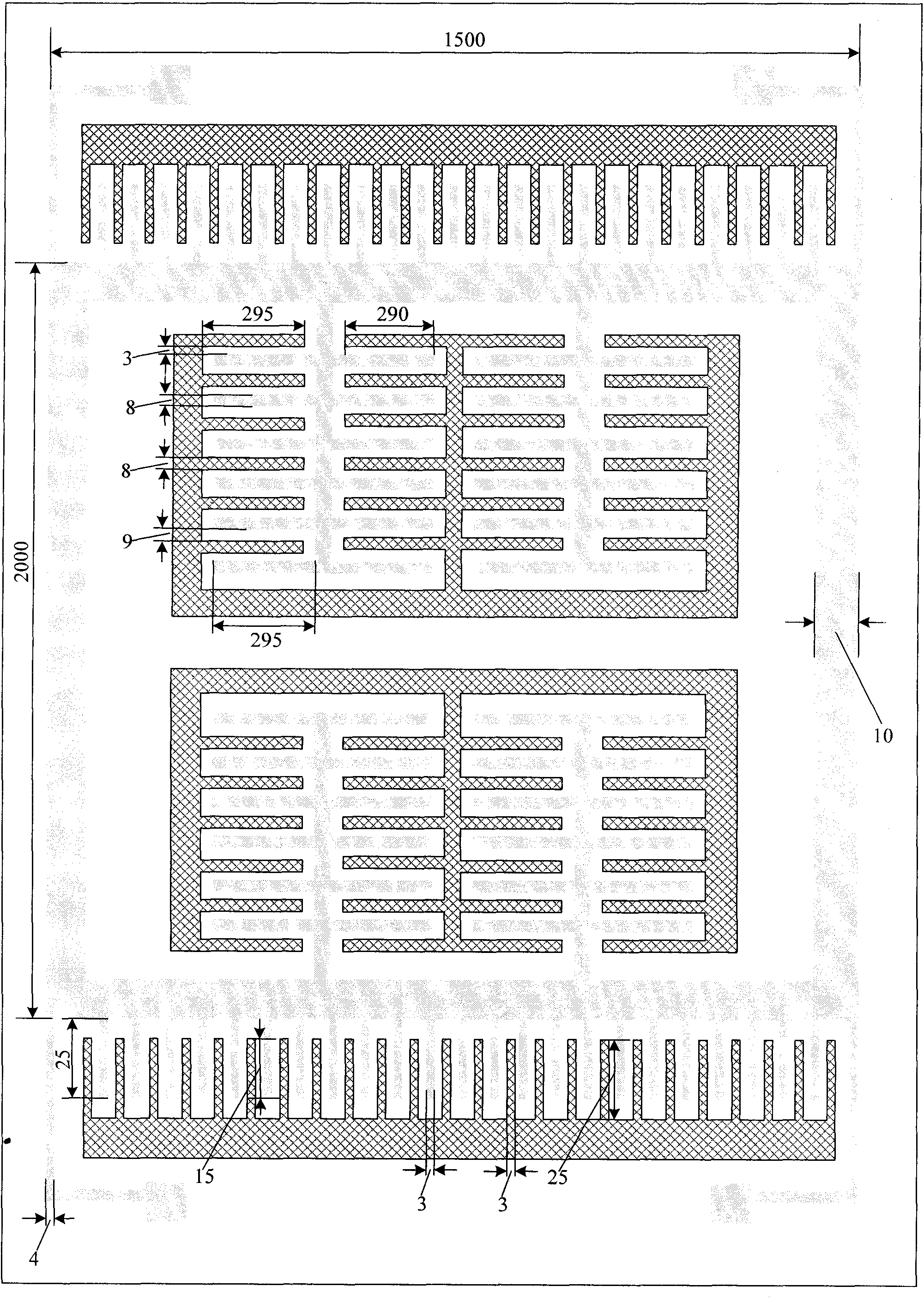

Method used

Image

Examples

Embodiment Construction

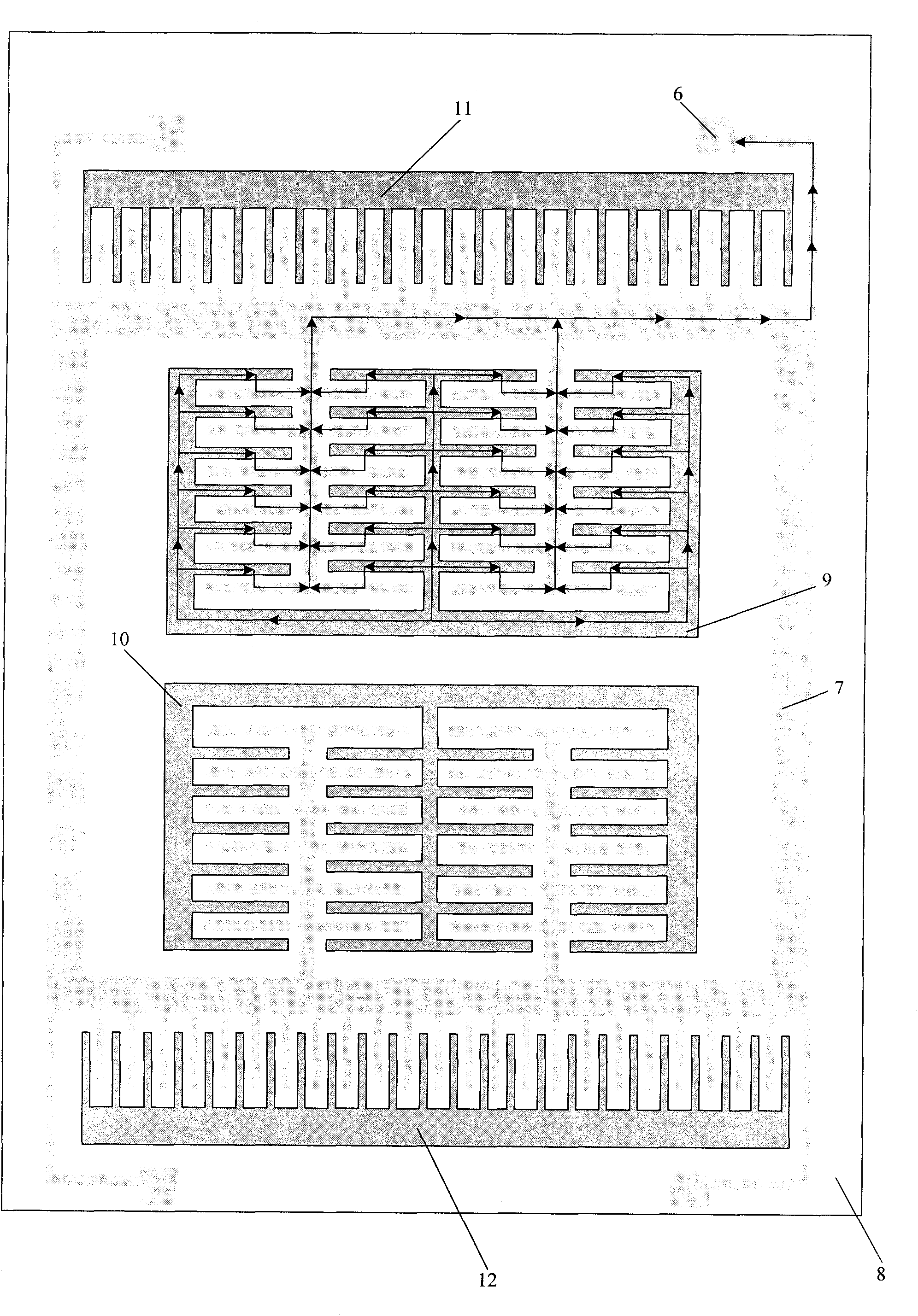

[0057] The process flow is as follows:

[0058] 1. The first photolithography, surface metallization peeling off;

[0059] 2. The second photolithography, deep reactive ion etching (Deep Reactive Ion Etch, DRIE) on the front to form the front structure;

[0060] 3. The front structure is protected by Polyimide, forming a front protection, and supporting the front structure has been formed;

[0061] 4. The third photolithography, deep groove DRIE on the back substrate layer, forming the back window structure;

[0062] 5. The back structure is etched by HF acid wet method to remove the oxide layer structure under the corresponding structure in the SOI sheet;

[0063] 6. Remove the front polyimide protective layer to release the structure;

[0064] 7. Use the shadow mask version of the shadow mask to complete the metal patterning of the corresponding position on the surface of the SOI sheet and prepare for electrical connection.

[0065] Due to the need to reduce the driving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com