Underwater pulse laser welding method and device for ocean platform

An offshore platform, pulsed laser technology, applied in laser welding equipment, welding equipment, transportation and packaging, etc., can solve the problems of low cost, difficult to adapt to deep sea operations, etc., to improve welding quality, realize welding automation, and ensure reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

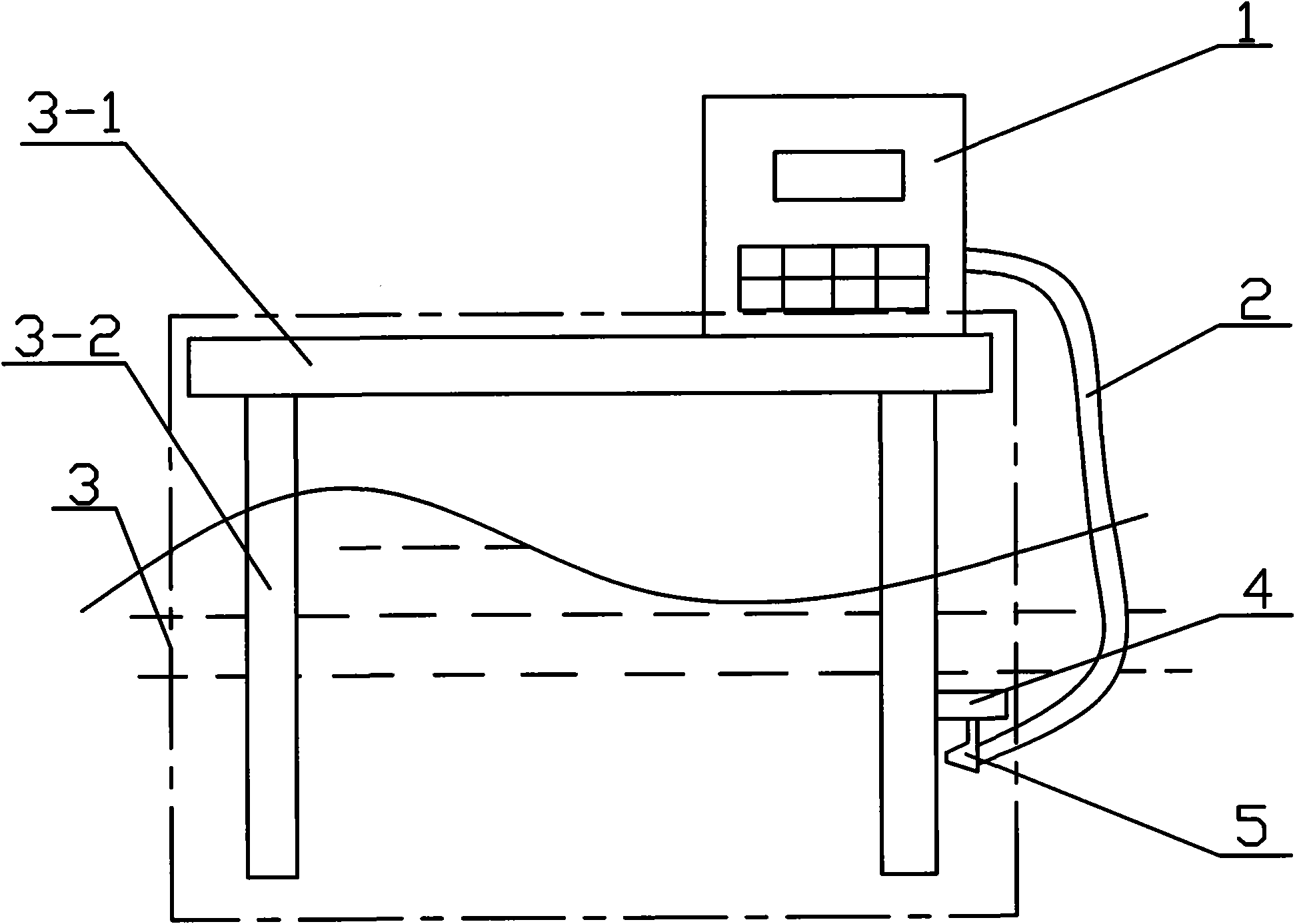

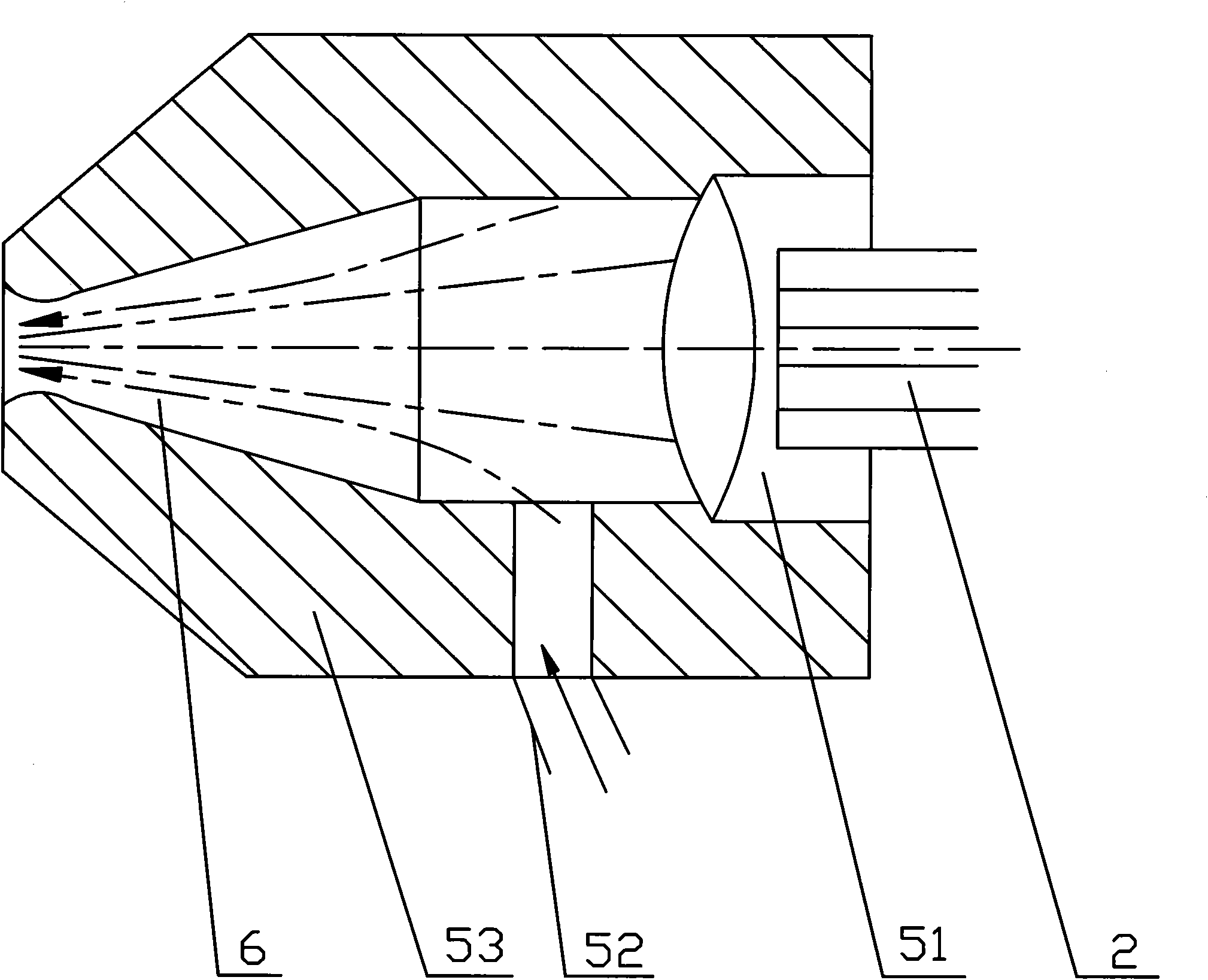

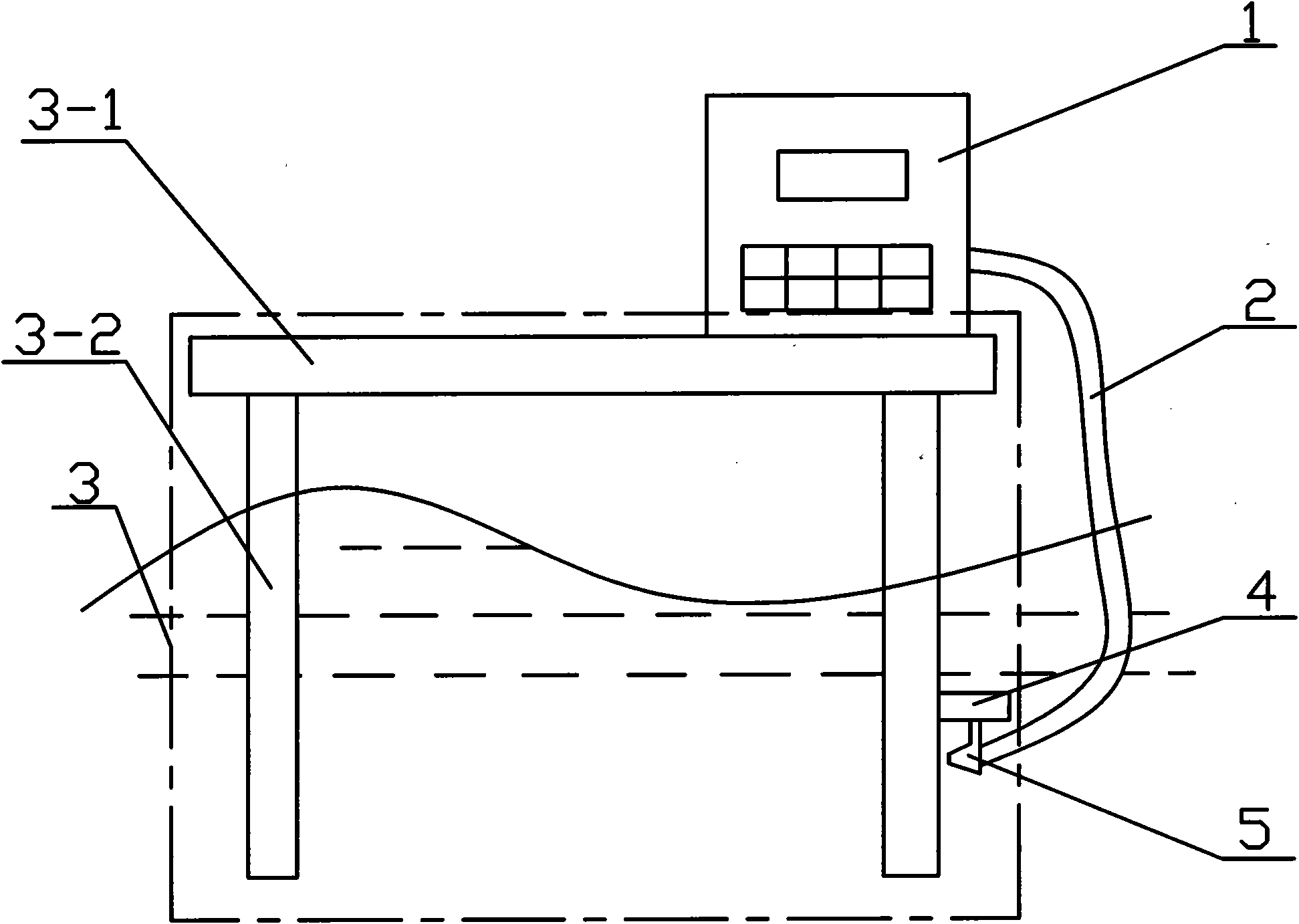

[0019] Such as figure 1 It shows an embodiment of an underwater pulse laser welding device for an offshore platform of the present invention, including an offshore platform 3, which includes a table 3-1 and a bracket 3-2, and a laser 1 is provided on the table 3-1 , a robot hand 4 is arranged on the side wall of the bracket 3-2, a laser welding head 5 is connected to the bottom of the robot hand 4, a cavity 6 is formed inside the laser welding head 5, and the laser 1 and the laser welding head 5 pass through the transmission optical fiber 2 Connect, laser welding head 5 comprises welding head nozzle 53, and transmission optical fiber 2 is connected with one end of welding head nozzle 53, and the below of laser welding head 5 is provided with shielding gas pipeline 52, and one end of shielding gas pipeline 52 is connected with laser welding head 5 The cavity of the laser welding head 5 is connected with each other, and a focusing lens 51 is provided at one end of the laser weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com