Vent gas treatment method and treatment device

A processing method and technology for processing devices, which are applied in separation methods, chemical instruments and methods, gas fuels, etc., can solve problems such as loss of pressure and waste of hydrocarbons.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] There are two methanol synthesis purge gas components of the same composition: H 2 60.0%, CH 4 +C n h m 31.45%, CO 6.5%, CO 2 1.5%, N 2 0.5%, O 2 0.05%.

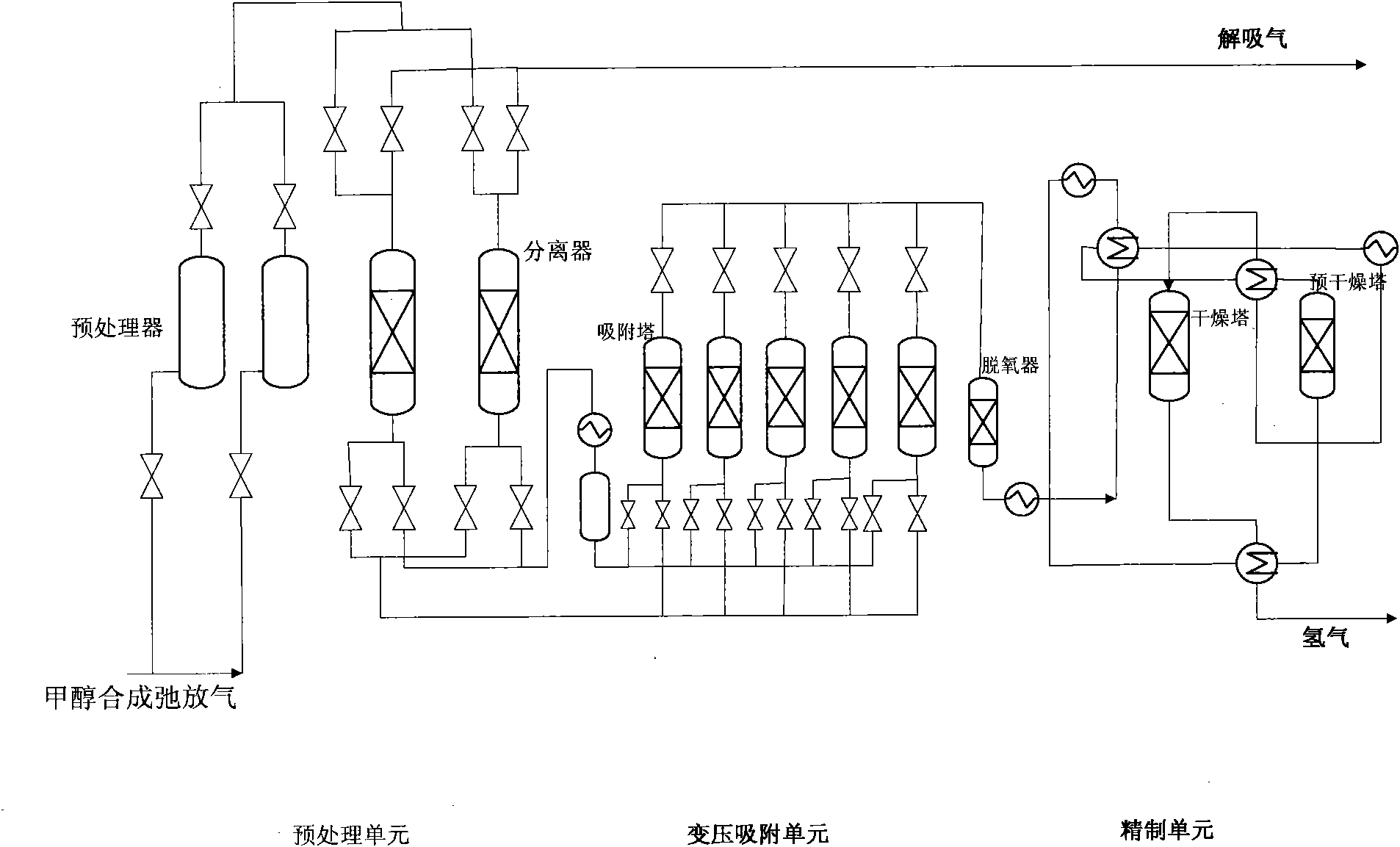

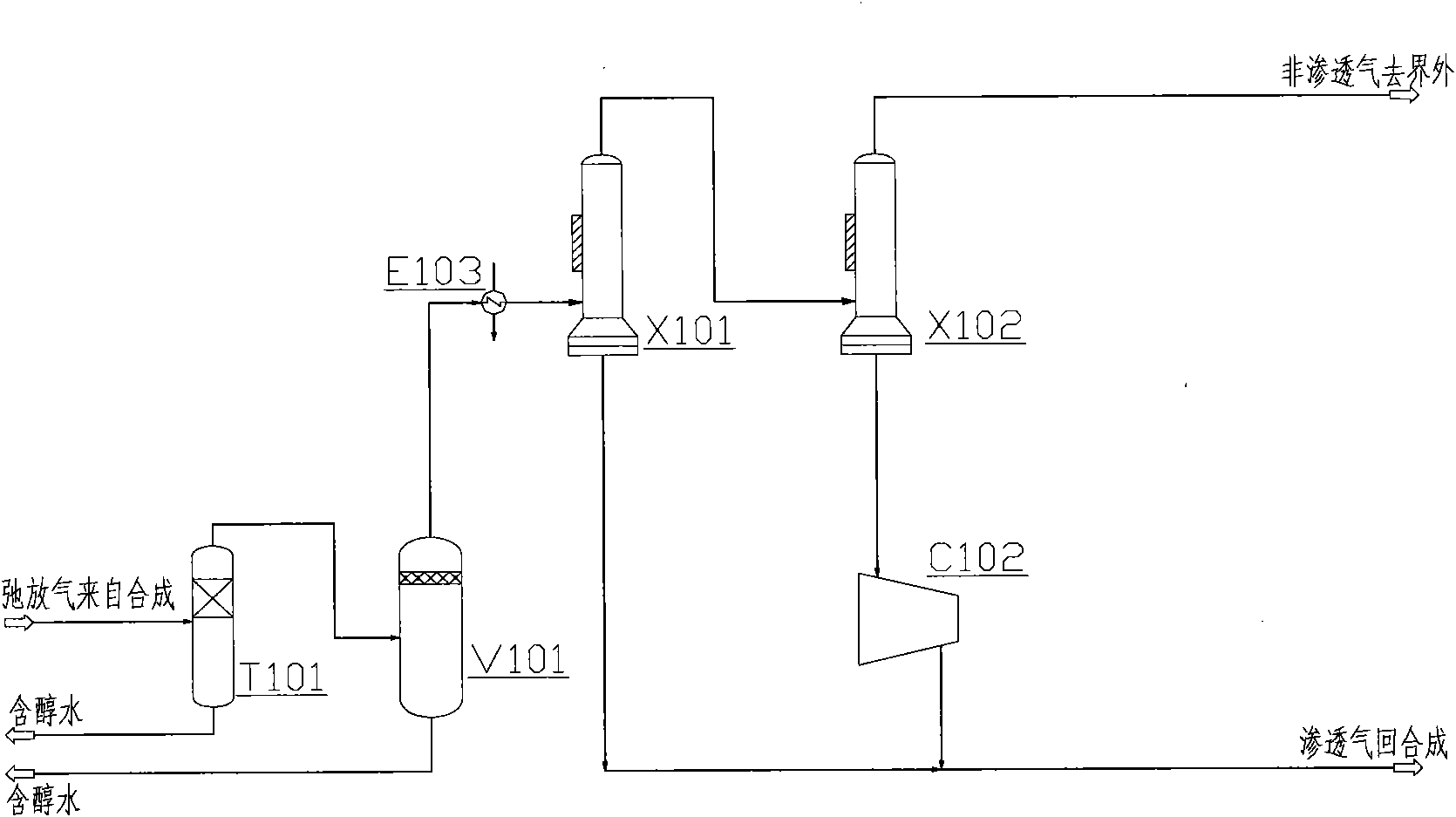

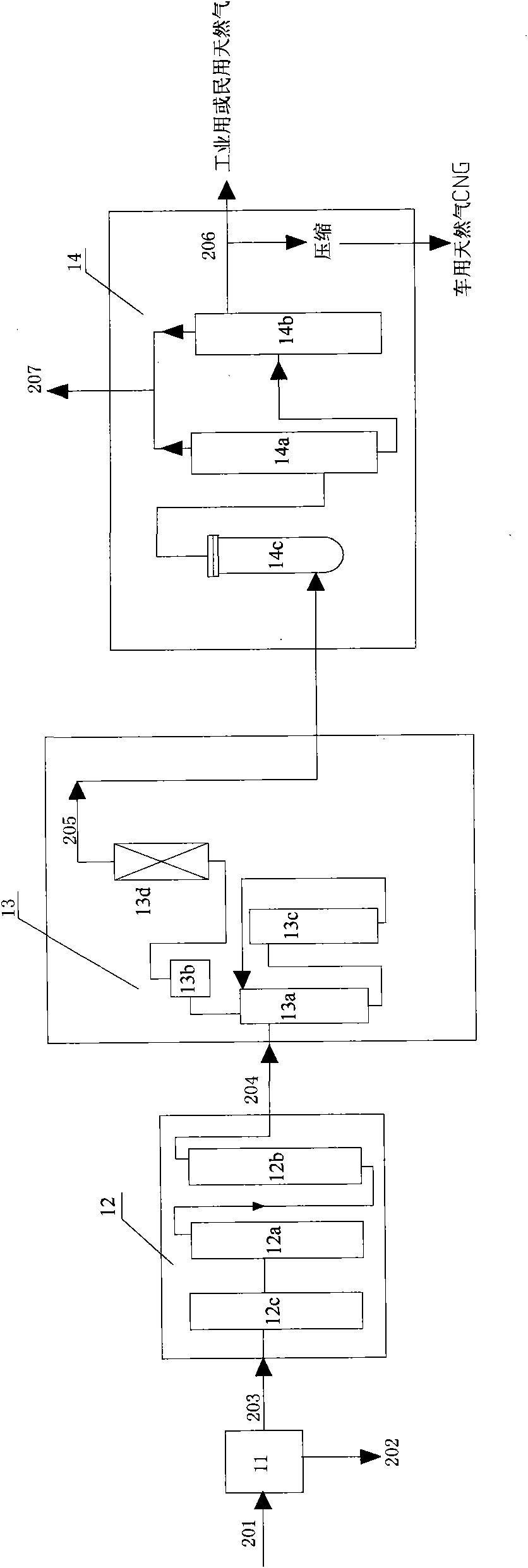

[0056] The pressures of the two release gases are 7.0MPa and 4.4MPa respectively, and the total flow rate is 44400Nm 3 / h, the relaxation gas 201 first enters the water washing tower for water washing to remove the methanol in the feed gas, and the relaxation gas leaving the water washing tower has a small amount of mist, and is then sent to the gas-liquid separator to remove the entrained mist The purge gas leaving the gas-liquid separator is sent into the first membrane separation device to contact with the separation membrane module to obtain a first hydrogen-rich gas stream 202 and a first target gas stream 203 . Wherein, the flow rate of the first hydrogen-rich gas flow 202 is 21757.27Nm 3 / h, the pressure is 2.2MPa, the composition is: H 2 93.002%, CH 4 +C n h m 3.858%, CO 2 1.443%, CO 1.583%, N 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com