Manufacturing method of internal bladder of annular titanium alloy gas cylinder

A manufacturing method and technology of titanium alloy, applied in the direction of manufacturing tools, metal processing equipment, auxiliary devices, etc., can solve the problems of deformation of titanium alloy liner, difficulty in applying gas protection backing plate, and difficulty in guaranteeing the shape of weld seam on the inner surface of the liner, etc. , to achieve excellent high pressure resistance and solve the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

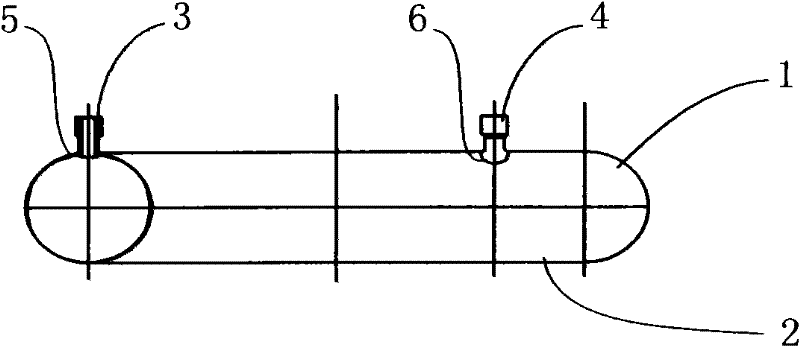

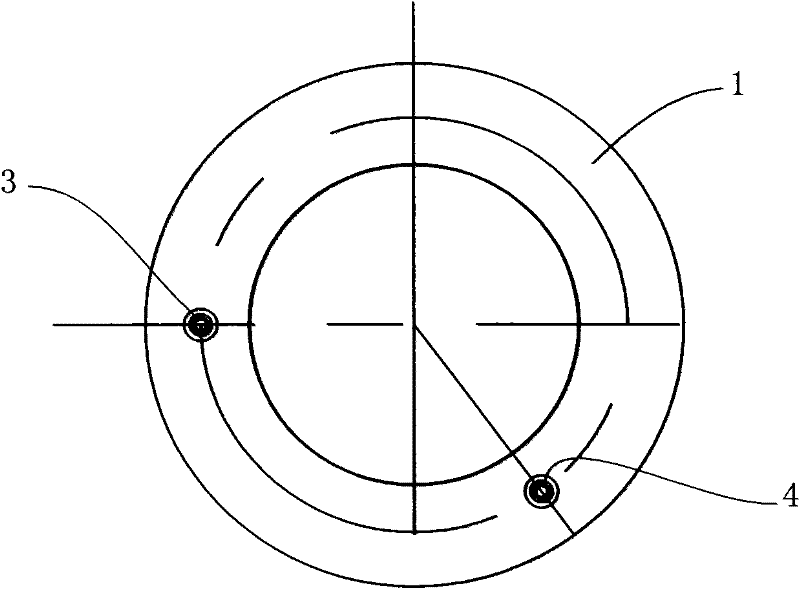

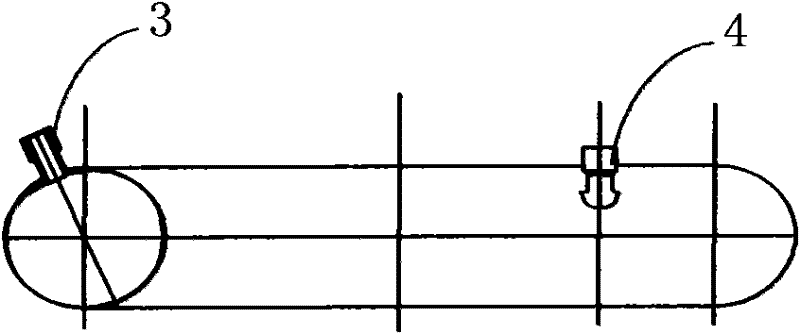

[0034] Such as Figure 5 Shown, the manufacture method of the titanium alloy annular gas cylinder liner provided by the present invention comprises the following steps:

[0035] (1) Forge and press 0.5-6mm thick TC4 plate to form two titanium alloy circular semicircular tubes; the specific thickness of the plate is determined according to the pressure resistance and processing requirements of the gas cylinder;

[0036] (2) hole in the position of the air inlet and outlet holes of the titanium alloy circular semicircular pipe; the diameter of the hole is equal to the diameter of the circular welding flanges 5,6 on the air inlet and outlet pipes. In order to improve the quality of the welds and avoid the use of fillet welds, the inlet and outlet pipes are provided with a circular welding flange, the thickness of the welding flange is the same as that of the wall of the circular semicircular pipe;

[0037] (3) In the vacuum argon-filled protective chamber, the inlet nozzle and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com