Liquid resin composition for electronic component and electronic component device

A technology for resin compositions and electronic components, which is applied in the fields of electrical components, electric solid devices, semiconductor/solid device components, etc., can solve the problems of high-purity liquid resin compositions that are difficult to adapt to, and achieves low water absorption and adhesive properties. Good viscosity and good migration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

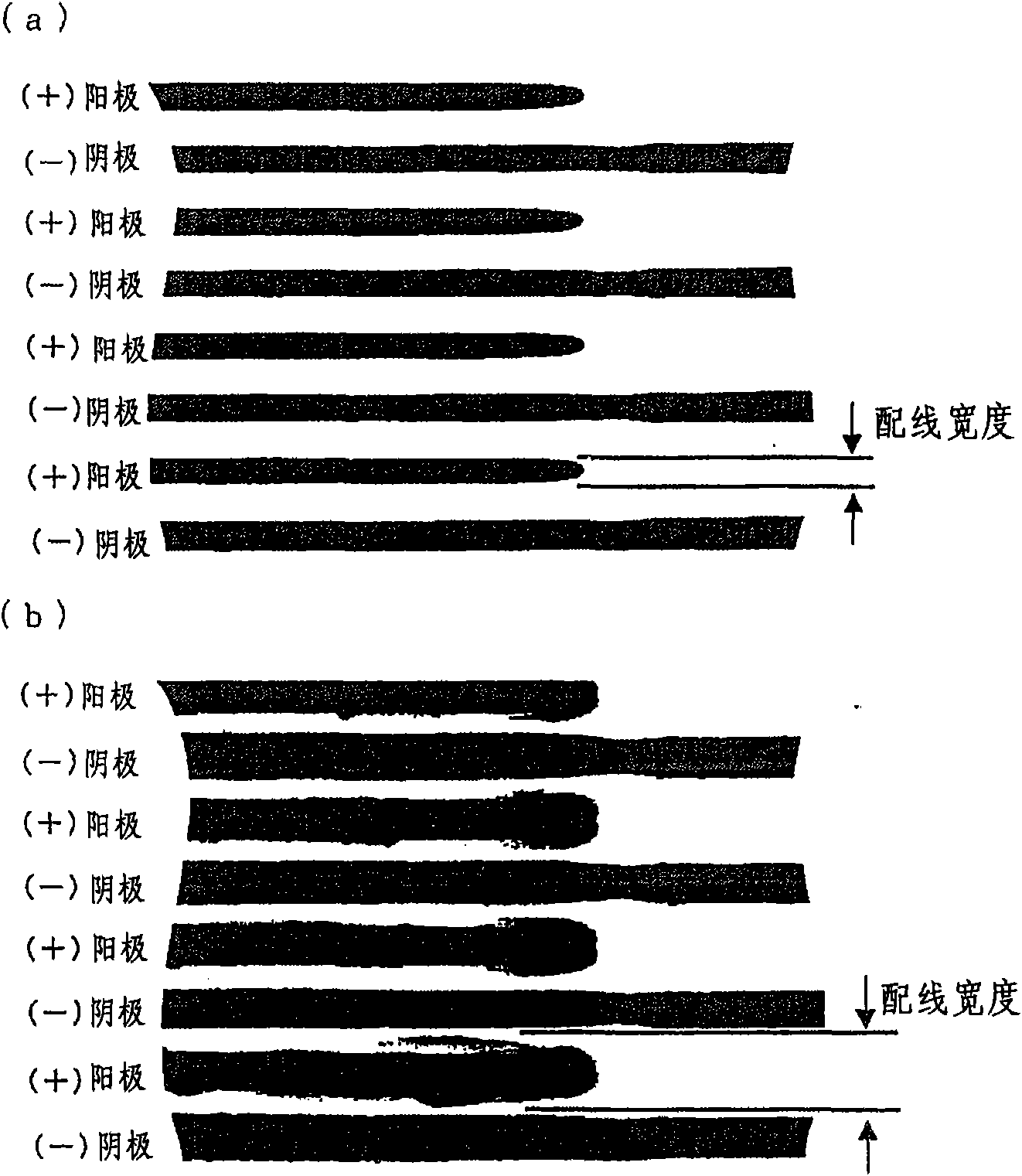

Image

Examples

Embodiment 1~5

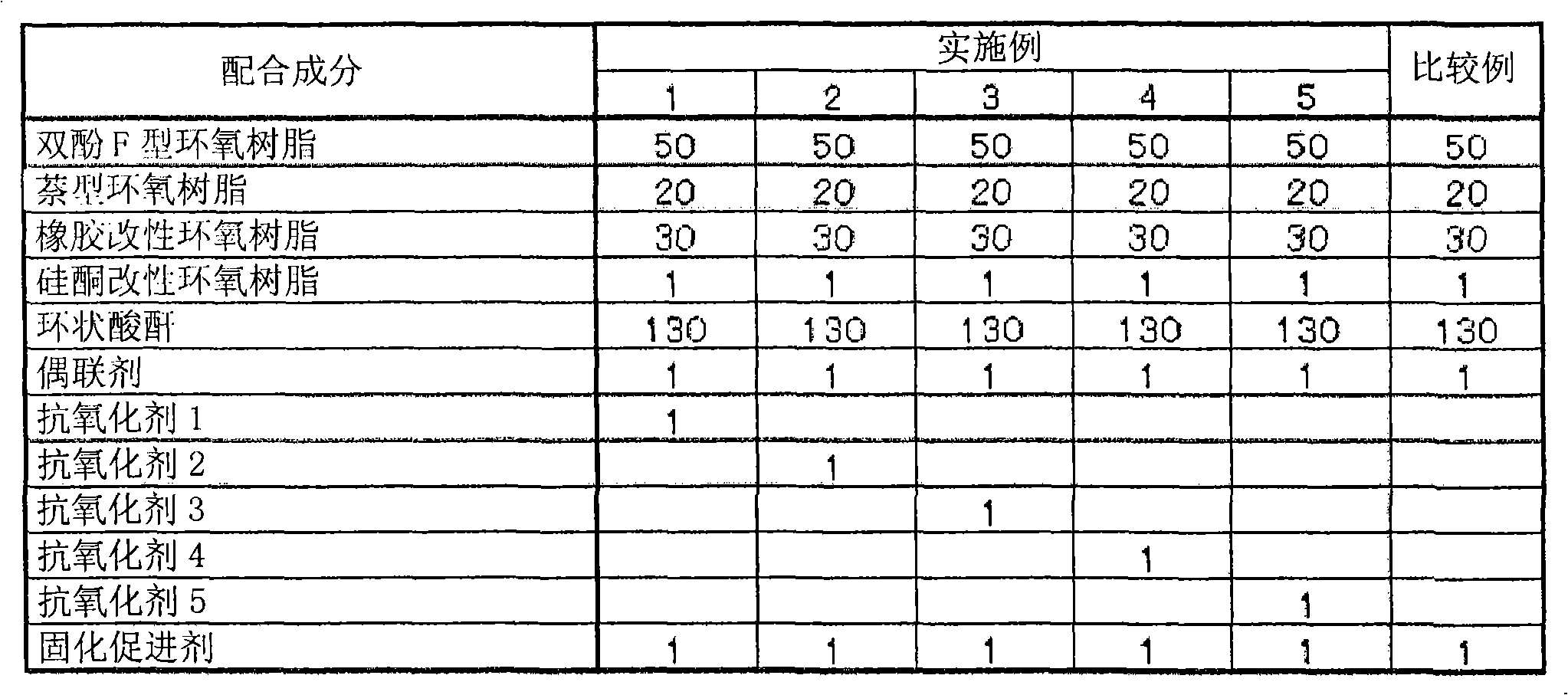

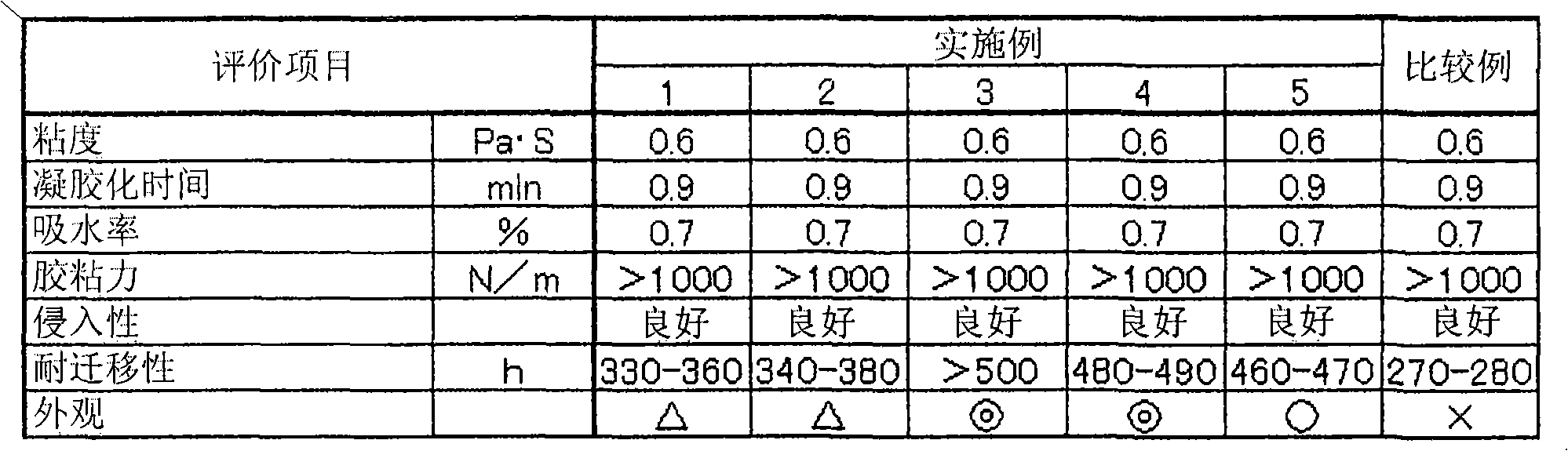

[0109] (Examples 1 to 5 and Comparative Example)

[0110] (A) as epoxy resin

[0111] Bisphenol F type liquid epoxy resin with an epoxy equivalent of 160 (trade name YDF-8170C manufactured by Tohto Chemical Co., Ltd.),

[0112] Naphthalene-type epoxy resin with an epoxy equivalent of 140 (trade name HP-4032 manufactured by Dainippon Ink Industry Co., Ltd.),

[0113] as a rubber particle component

[0114] Make acrylonitrile-butadiene-methacrylic acid-divinylbenzene copolymer (trade name XER-91P manufactured by JSR Corporation) in bisphenol F type liquid epoxy resin (YDF-8170C) at a mass ratio of 1 / 4 The rubber-modified epoxy resin that has been heat-miscible and micro-dispersed in advance,

[0115] as leveling agent

[0116] Phenol-modified silicone with a hydroxyl equivalent of 750 (trade name BY16-799 manufactured by Toray Dow Corning Silicone Co., Ltd.) and bisphenol F-type liquid epoxy resin (YDF-8170C) are heated and mixed at a mass ratio of 1 / 1 The obtained silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com