Tube refrigerant oil-bearing evaporation/condensation heat transfer testing integrated device and test method thereof

A refrigerant and refrigerant circuit technology, which is applied in the field of integrated refrigerant oil evaporation/condensation heat transfer test device in the tube, can solve the problems of difficult matching of compressors, waste of funds, waste of resources, etc., to maintain oil balance and easy to use , the effect of continuous oil injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

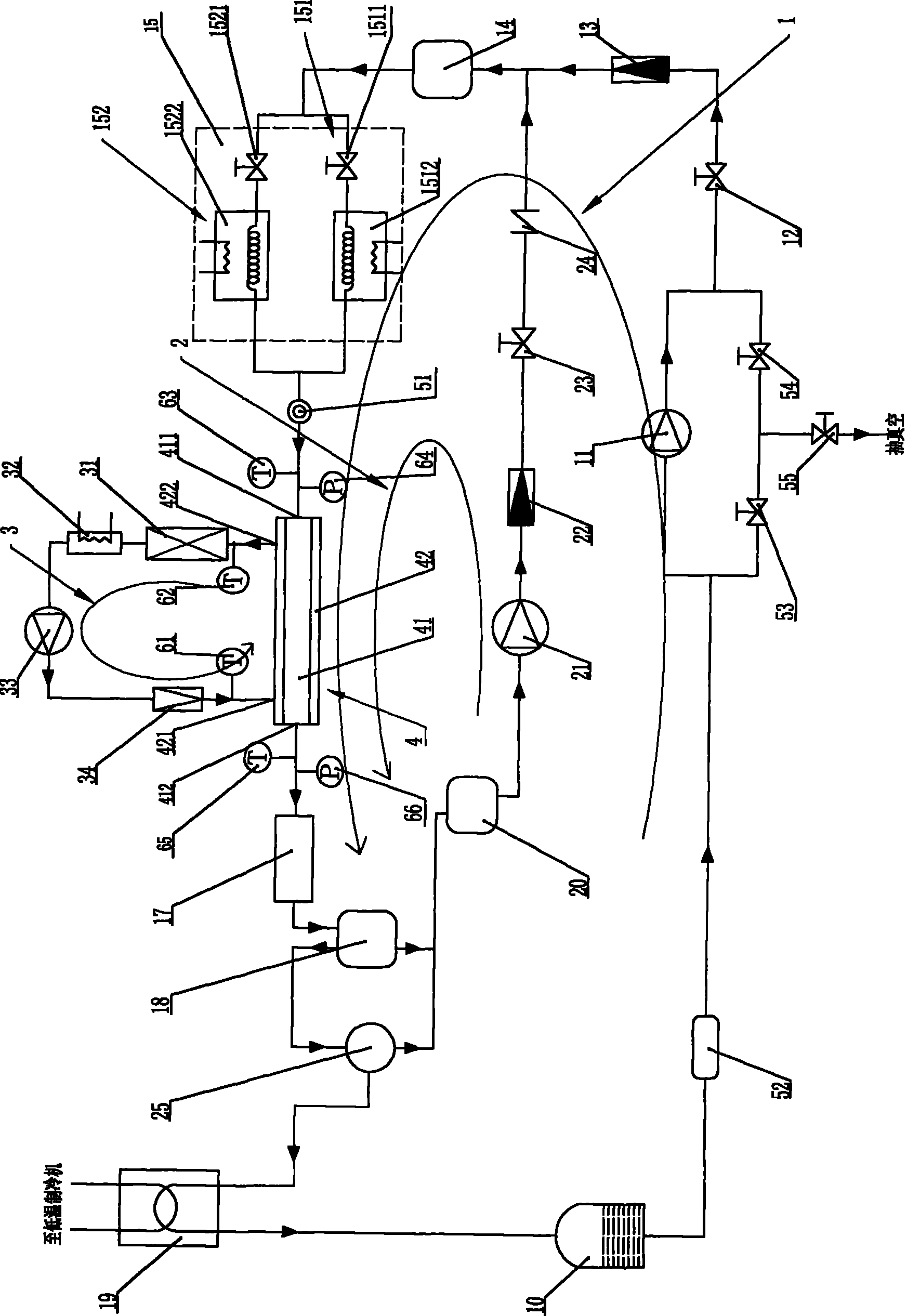

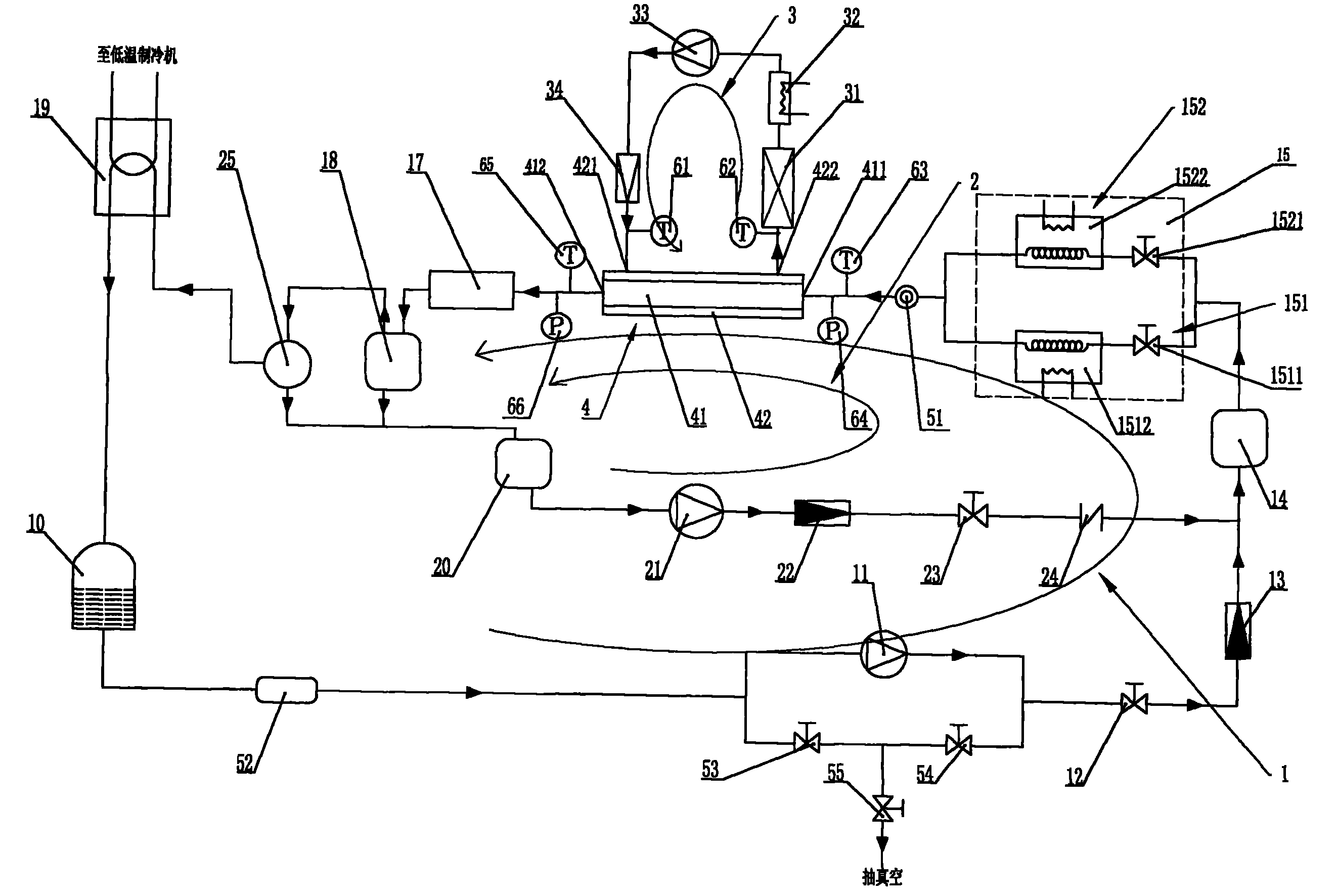

[0037] see figure 1 . The invention discloses an integrated device for testing the evaporation / condensation and heat transfer of refrigerant containing oil in a tube. The heat exchange medium in the test section can be water, oil or alcohol. The present invention takes water as an example, and other media are similar.

[0038] An integrated device for testing refrigerant oil in tubes containing evaporation / condensation and heat transfer of the present invention includes a refrigerant circuit 1, a lubricating oil injection circuit 2, an evaporation / condensation test section heat exchange circuit 3, and a heat exchange tube test section 4; wherein: The heat exchange tube test section 4 includes an inner tube 41 passing through the refrigerant and a sleeve 42 passing through the heat exchange medium. The refrigerant circuit 1 includes a condenser 19, a recovery tank 10, a power pump 11, a regulating valve 12, a refrigerant mass flow meter 13, a uniform mixing tank 14, and a par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com