Radiation-sensitive resin composition for forming spacer, spacer, method for forming spacer, and liquid crystal display device

A technology of resin composition and spacer, which is applied in the direction of nonlinear optics, photosensitive material processing, photoplate-making process of patterned surface, etc., can solve the problem of insufficient curing reaction, reduced service life, and increased cost of coating liquid. time stability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0290] Hereinafter, although an Example demonstrates this invention more concretely, unless the summary is exceeded, this invention is not limited to a following Example. In addition, unless otherwise specified, "%" and "part" are based on mass.

[0291] Synthesis of resin

[0292] As an example of (A) resin, the synthesis example of the compound P-4+St which added the structural unit derived from styrene to the said compound P-4 is shown below. However, the monomer ratio in Compound P-4 was changed from the monomer ratio shown above.

Synthetic example 1

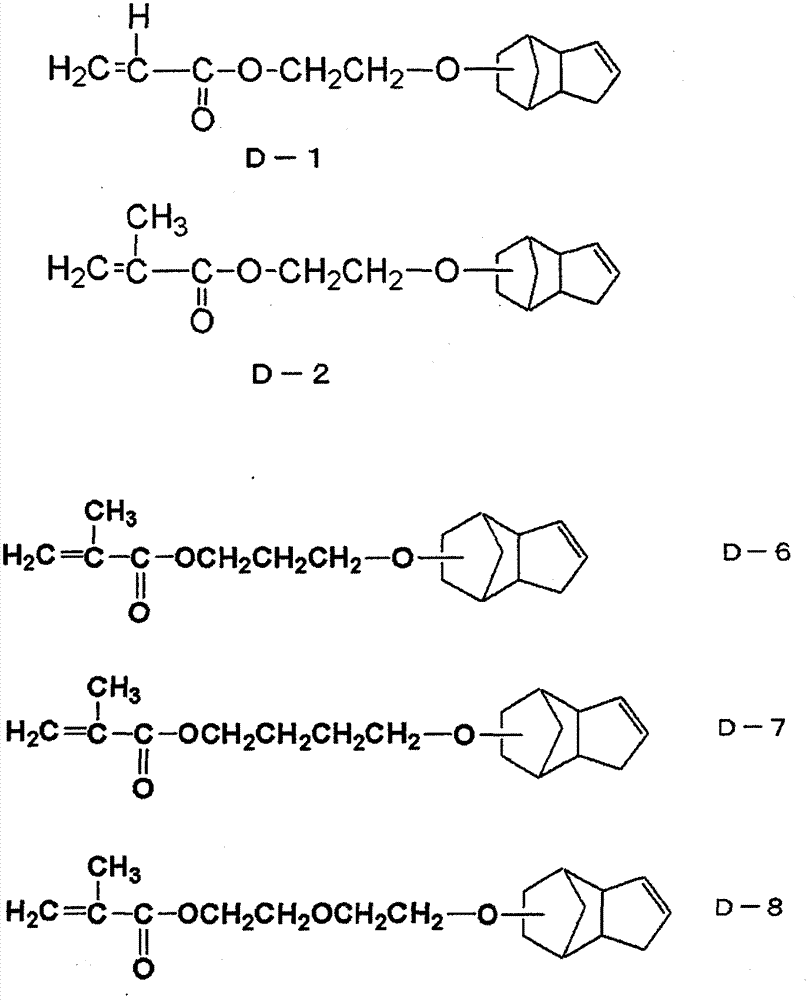

[0294] 7.48 parts of 1-methoxy-2-propanol (trade name: MFG, manufactured by Nippon Emulsifier Co., Ltd.) was added to the reaction vessel in advance, and the temperature was raised to 90°C. 3.1 parts of styrene (St; w), tricyclopentenyl methacrylate (TCPD-M (trade name) manufactured by Hitachi Chemical Industry Co., Ltd.; x) 4.28 parts, methacrylic acid (MAA; y ) 11.7 parts, a mixed solution consisting of 2.08 parts of an azo polymerization initiator (manufactured by Wako Pure Chemical Industries, Ltd., V-601 (trade name)), and 55.2 parts of 1-methoxy-2-propanol. After the dropwise addition, it was reacted for 4 hours to obtain an acrylic resin solution.

[0295] Next, 0.15 parts of hydroquinone monomethyl ether and 0.34 parts of tetraethylammonium bromide were added to the above-mentioned acrylic resin solution, and then 26.4 parts of glycidyl methacrylate (GLM, manufactured by Tokyo Chemical Industry Co., Ltd.) was added dropwise over 2 hours. parts (GLM-MAA; z). After the...

Synthetic example 2

[0301] The synthesis of the above compound P-4 was carried out as follows. However, the monomer ratio in Compound P-4 was changed from the monomer ratio shown above.

[0302] Except that styrene was not used in Synthesis Example 1, the addition amounts of TCPD-M(x), methacrylic acid (y) and GLM-MAA(z) were changed so that x:y:z in Compound P-4 was 34mol%: 27mol%: 39mol%, synthesized by the same method as in Synthesis Example 1 to obtain a resin solution (solid content acid value: 72.5mgKOH / g) of compound P-4 ((A) resin) having an unsaturated group , Mw: 22,000, 1-methoxy-2-propanol / 1-methoxy-2-propyl acetate 45% solution).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com