Electrochemical biological combined denitrification reactor

A technology of electrochemical biology and reactor, which is applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc. It can solve the problems of uncontrollable denitrification intensity, achieve small footprint and avoid sludge Expansive, compact and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

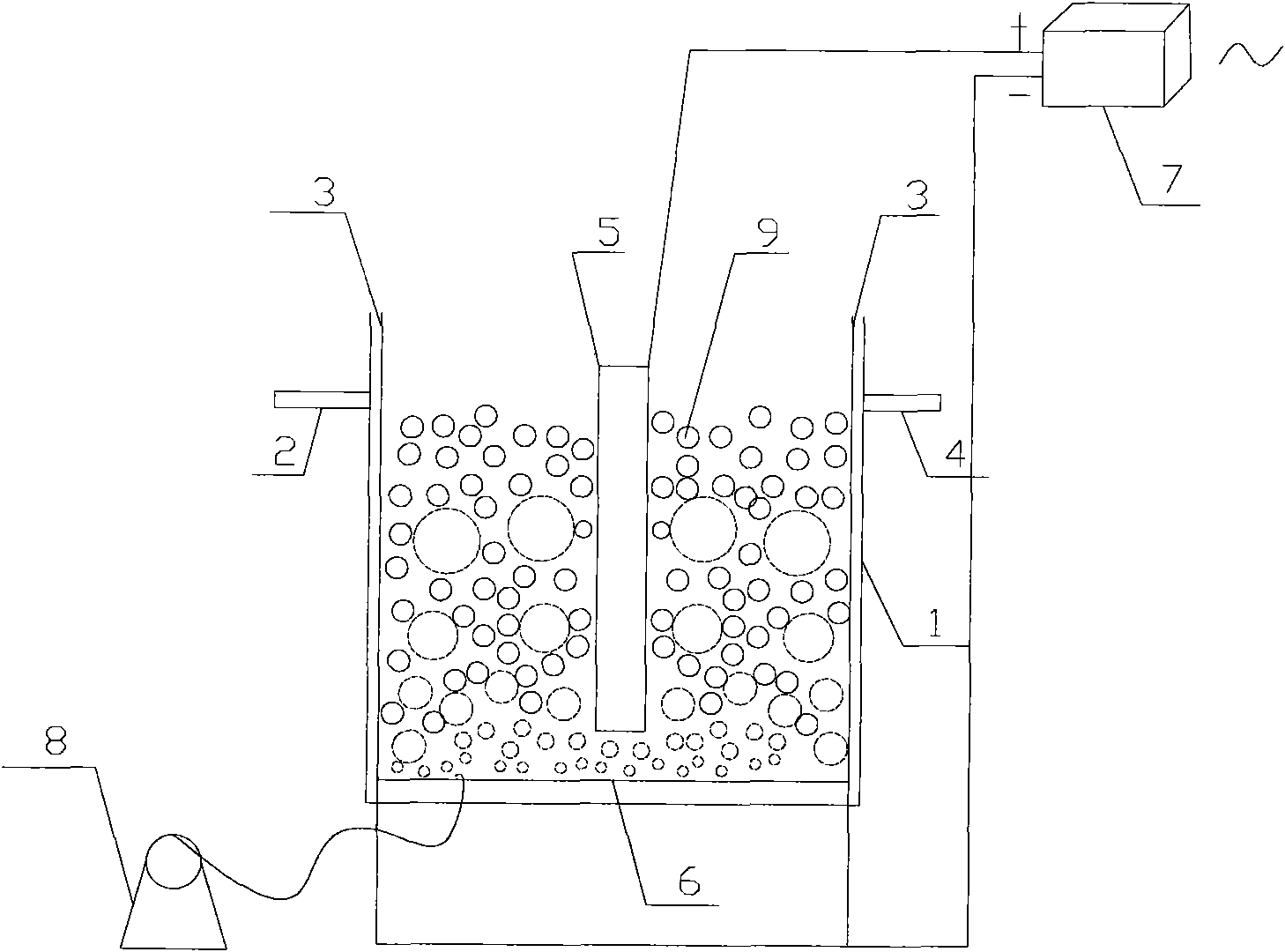

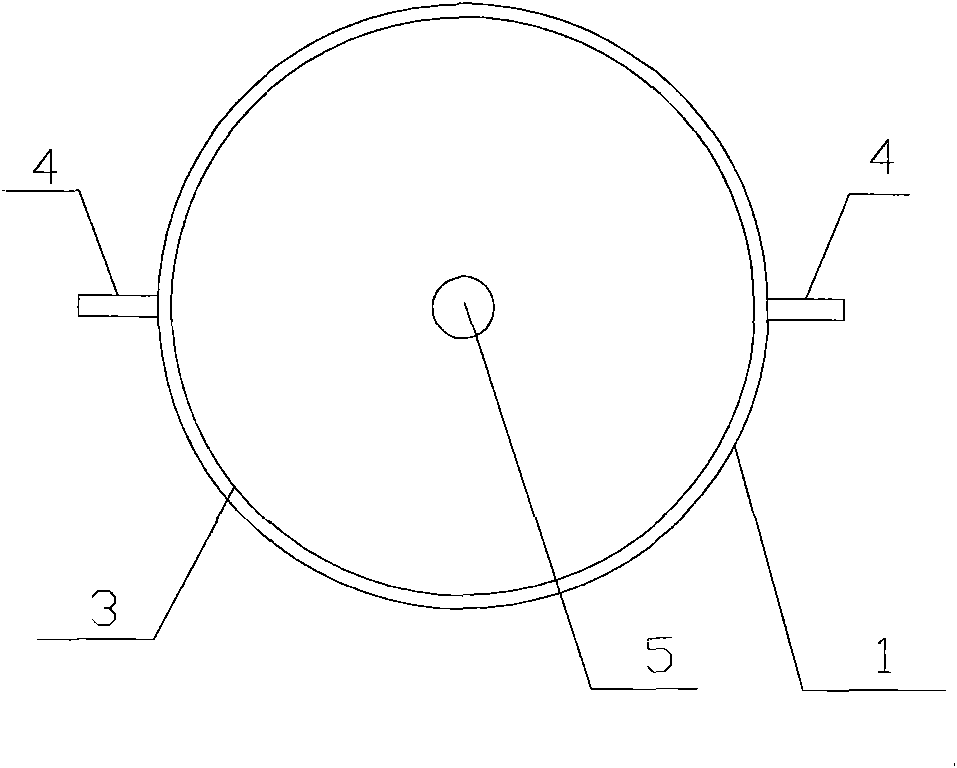

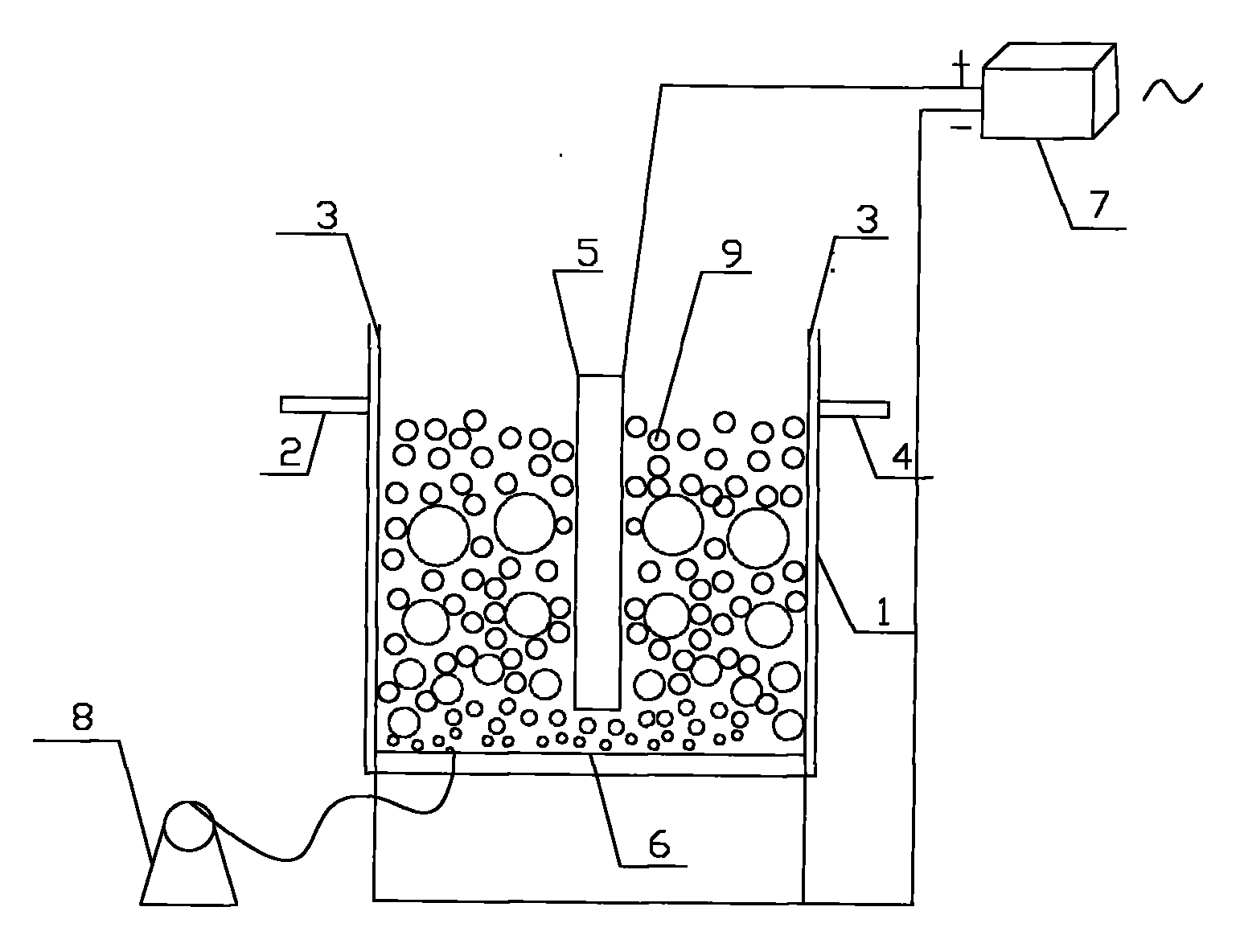

[0014] An electrochemical biological combined denitrification reactor, such as figure 1 , 2 As shown, it includes a cell body 1, an electrode, a modified activated carbon particle electrode 9, an aeration device 8 and a steady current transformer 7. The two ends of the cell body 1 are respectively provided with a water inlet 2 and a water outlet 4; the electrodes include an anode 5 and a cathode 3, the anode 5 is arranged in the center of the cell body 1, and the cathode 3 surrounds the anode 5 and is arranged near the cell wall. The material used for the anode 5 is a titanium plate, and the material used for the cathode 3 is graphite; the anode 5 and the cathode 3 are respectively connected to the positive and negative poles of the steady current transformer 7; the spherical modified activated carbon particle electrode 9 is filled between the anode 5 and the cathode 3; The aeration device includes a microporous aerator 6 arranged at the bottom of the pool body 1 and an air p...

Embodiment 2

[0017] The structure of the reactor is the same as in Example 1, the anode 5 is made of titanium-based lead dioxide-plated material, and the cathode 3 is made of stainless steel. Processing flow is the same as embodiment 1.

[0018] Using a complex three-dimensional electrode-biofilm reactor with a titanium-based lead dioxide-plated material as the anode and a stainless steel cathode as the direct treatment of COD to 45mg / L, NH 3 -N=30mg / L, TN is 40mg / L simulated wastewater, under the conditions of T=28℃, DO=1.2mg / L, HRT=8h, I=25mA, the effluent COD is 30mg / L, TN=3.2mg / L, NH 3 - N = 1.9 mg / L.

Embodiment 3

[0020] The structure of the reactor is the same as in Example 1, the anode 5 is made of titanium-based ruthenium dioxide plated plate material, and the cathode 3 is made of graphite material. Processing flow is the same as embodiment 1.

[0021] Using a complex three-dimensional electrode-biofilm reactor with a titanium-based ruthenium dioxide-coated material as the anode and a graphite material as the cathode, the COD is 45mg / L and NH is directly processed. 3 - Simulated wastewater with N=30mg / L and TN of 40mg / L was carried out under the same conditions as Case 2: T=28°C, DO=1.2mg / L, HRT=8h, I=25mA, and the effluent COD was 26mg / L, TN=1.1mg / L, NH 3 - N = 0.82 mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com