Novel high-temperature-resistance 1, 7-bis(alkyl hydrogen silane)-carborane/phenylethynyl silane hybrid resin and preparation method thereof

A technology of ethynyl silane and alkyl hydrogen silane, which is applied in the field of new polymer materials and its preparation, and achieves broad application prospects, convenient operation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First, mix 100 parts of methyl toluene silane resin (parts by mass), 10 parts of 1,7-bis(dimethylhydrogensilane)-carborane in acetone, and after completely dissolving, add chlorine The acetone solution of platinum acid (concentration is 100ppm), the reaction temperature is 56°C, and the reaction time is 24h. After the reaction is completed, the solvent is distilled off by heating to prepare a 1,7-bis(dimethylhydrogensilane)-carborane / methyl tolanylsilane hybrid resin.

Embodiment 2

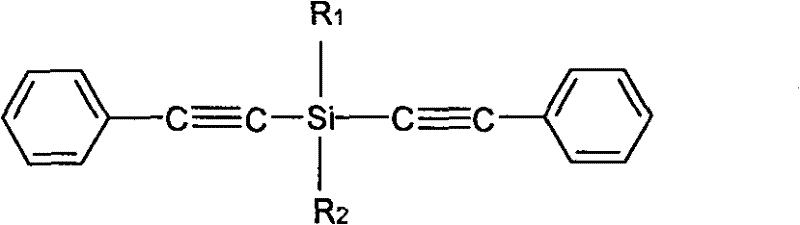

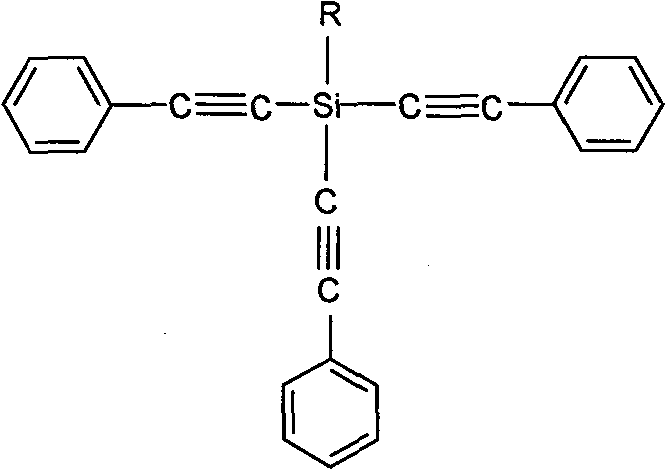

[0034] First, mix 100 parts (parts by mass) of methyl triphenylethynyl silane resin and 20 parts of 1,7-bis(methylphenylhydrosilane)-carborane in acetone, and after completely dissolving, add dropwise The Wllkinson catalyst (concentration is 300ppm), the reaction temperature is 56°C, and the reaction time is 24h. After the reaction, the solvent was distilled off by heating to prepare 1,7-bis(methylphenylhydrogensilane)-carborane / methyltriphenylethynylsilane hybrid resin.

Embodiment 3

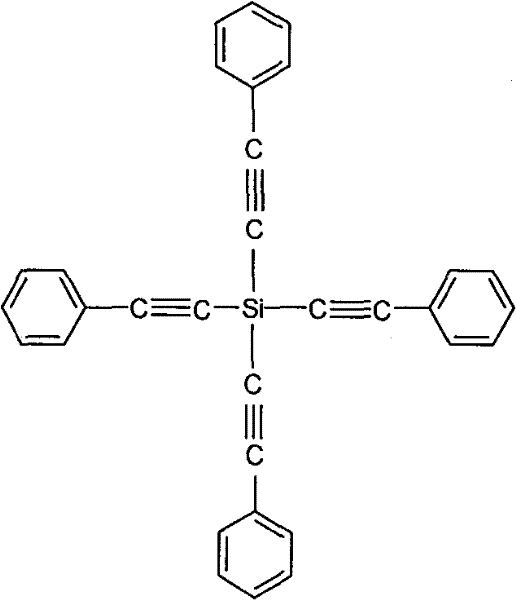

[0036] First with 100 parts (mass parts) of tetraphenylethynyl silane resin, 30 parts of 1,7-bis(diphenylhydrosilane)-carborane, mix in acetone, after completely dissolving, add dropwise Karstedt catalyst ( The concentration is 300ppm), the reaction temperature is 56°C, and the reaction time is 24h. After the reaction is finished, the solvent is distilled off by heating to prepare 1,7-bis(diphenylhydrosilane)-carborane / tetraphenylethynylsilane hybrid resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com