High-temperature insulation composite, insulated conductor and magnetic element

A technology for insulated wires and magnetic components, applied in the fields of insulated wires and magnetic components, high temperature resistant insulating compositions, and insulating compositions, can solve the problems of low production efficiency, high assembly difficulty and cost, and low space utilization of magnetic components, etc. Achieve the effect of improving power density and performance, reducing manufacturing costs, and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] In the present invention, the organic material can be DowCorning's silicone resin OE6630, and the inorganic bonding material can be glass powder (preferably glass powder for sealing) with a softening temperature of about 450 degrees Celsius and a particle size of about 10 μm. The weight percentage content is in 10%-90%. Subsequently, the composition is evenly coated on the surface of the wire, baked and cured. After the cured insulating coating layer is sintered at 650 degrees Celsius for a period of time, the strength and insulating properties of the sintered product are still good. In this embodiment, its volume resistivity is higher than 1Mohm.m, and when the glass powder content is more than 40% , the strength is higher than ordinary iron aluminum silicon (FeAlSi).

Embodiment 2

[0044] In the present invention, the organic material can be polyimide, and the inorganic bonding material is glass powder (preferably glass powder for sealing) with a softening temperature of about 450 degrees Celsius and a particle size of about 10 μm, wherein the weight percentage of the glass powder In 10%-90%. Subsequently, the composition is evenly coated on the surface of the wire, baked and cured. After the cured insulating coating layer is sintered at 600 degrees Celsius for a period of time, the sintered product has good strength and insulation performance, and its volume resistivity is higher than 1 Mohm.m in this embodiment.

Embodiment 3

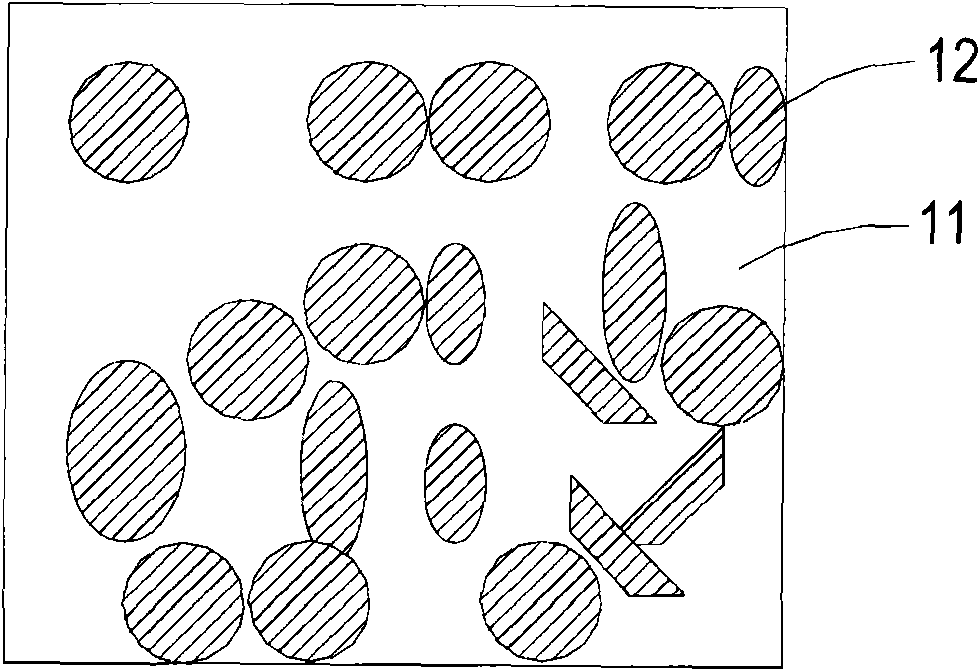

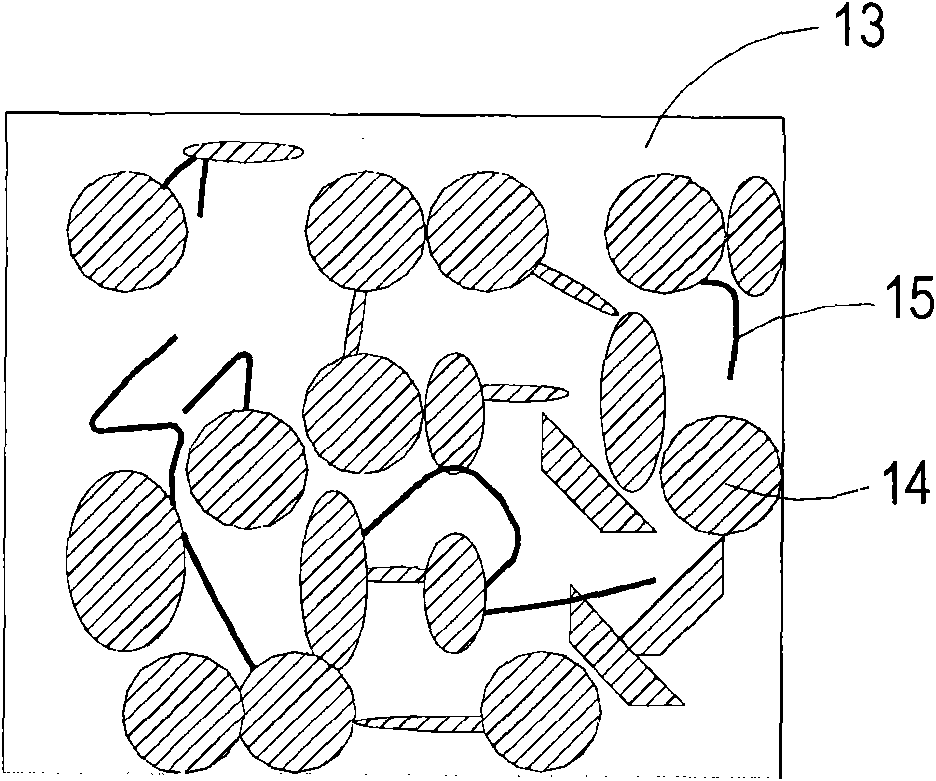

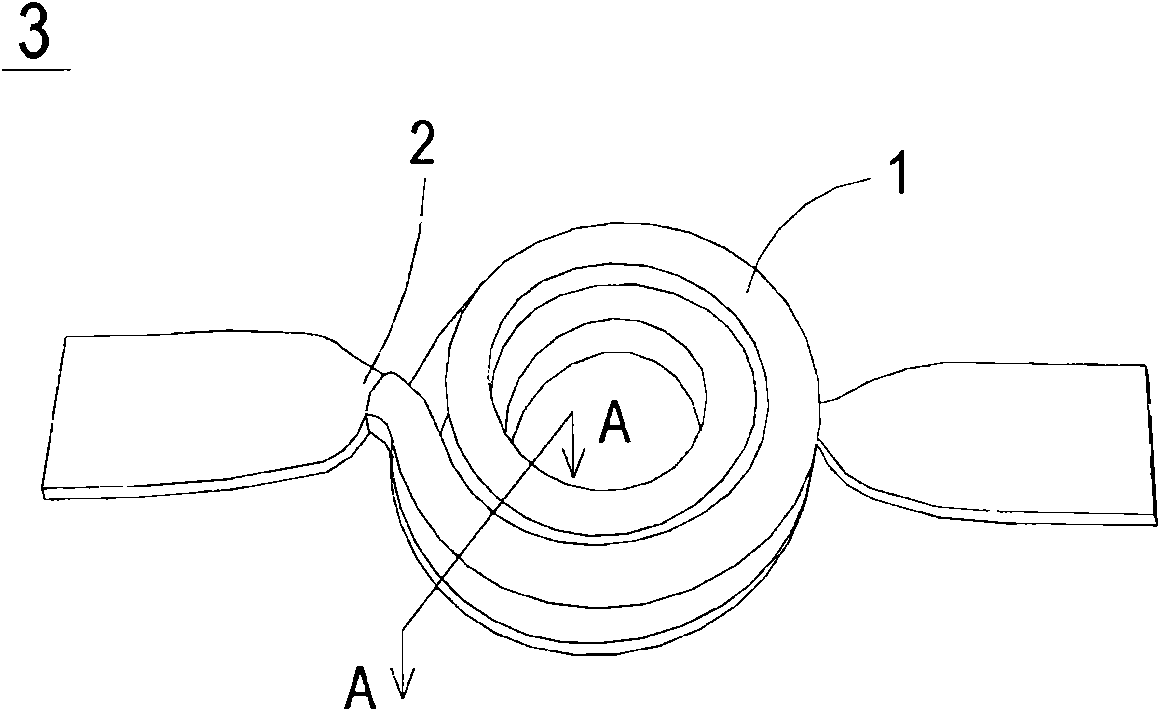

[0046] In the present invention, the organic material can be DowCorning's silicone resin OE6630, and the inorganic bonding material can be glass powder (preferably glass powder for sealing) with a softening temperature of about 450 degrees Celsius and a particle size of about 10 μm. The high temperature resistant insulating composition is formulated with the inorganic bonding material in equal proportions of 10:10, 10:7, 10:6 and 10:4. Subsequently, these compositions are respectively uniformly coated on the surface of the wire, baked and cured, wherein the thickness of the insulating coating layer applied to the surface of the wire (such as copper wire) is about 30 μm. Then, the insulated wire is wound into an insulated coil, and embedded in iron-aluminum-silicon (FeAlSi) magnetic material powder at, for example, 20 ton / cm 2 pressure compression molding. Subsequently, after annealing at 650 degrees Celsius for about one hour, the obtained magnetic components, such as inducto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com