Double sided adhesive tape

A double-sided, adhesive tape technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of difficulty in imparting water resistance, damage between foam substrate layers, and difficulty in achieving water resistance, etc., to achieve Effect of imparting waterproof function, preventing intrusion, and excellent waterproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

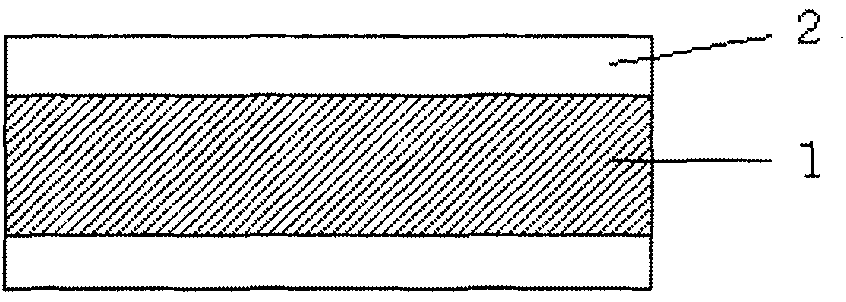

[0125] (Preparation of double-sided adhesive tape)

[0126] With respect to 100 parts by mass of the above-mentioned adhesive solution A, 1.24 parts by mass of "Coronet (Coronet) L-45" (isocyanate-based crosslinking agent, 45% solid content) manufactured by Nippon Polyurethane Co., Ltd. ), stirred for 15 minutes, and then coated on a peel-treated PET film with a thickness of 75 μm to a thickness of 35 μm after drying, and dried at 80° C. for 3 minutes to form an adhesive layer.

[0127] Next, in the white polyolefin foam (thickness: 130 μm, expansion ratio 2.5 times, 25% compressive strength: 130kPa, tensile modulus: 1140N / cm 2 , Tensile strength 14.8N / cm, the surface corona treated wettability index of 52mN / m) on both sides, after pasting each of the above-mentioned adhesive sheets, a roller with a linear pressure of 5kg / cm was used for lamination. Thereafter, it was aged at 40° C. for 48 hours to obtain a double-sided adhesive sheet with a thickness of 200 μm.

Embodiment 2~5

[0129] Both sides were obtained by the same method as in Example 1, except that the foam substrate described in Table 1 was used instead of the white polyolefin-based foam, and the thickness of the adhesive after drying was changed to the thickness shown in Table 1. Adhesive tape.

Embodiment 6

[0131]In the same manner as in Example 1, except for adding 0.8 parts by mass of Nippon Polyurethane Co., Ltd. "Kronet L-45" (isocyanate-based crosslinking agent, solid content 45%) to 100 parts by mass of adhesive solution A, method to obtain double-sided adhesive tape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com