Heat-collecting tube applied to polymer-base solar heat collector

A solar collector and collector tube technology, applied in the field of collector tubes, can solve the problems of solar collector tube fittings research limitations, poor thermal insulation effect, poor heat collection effect, etc., and achieves good heat collection effect, long service life, excellent The effect of heat collection efficiency and thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

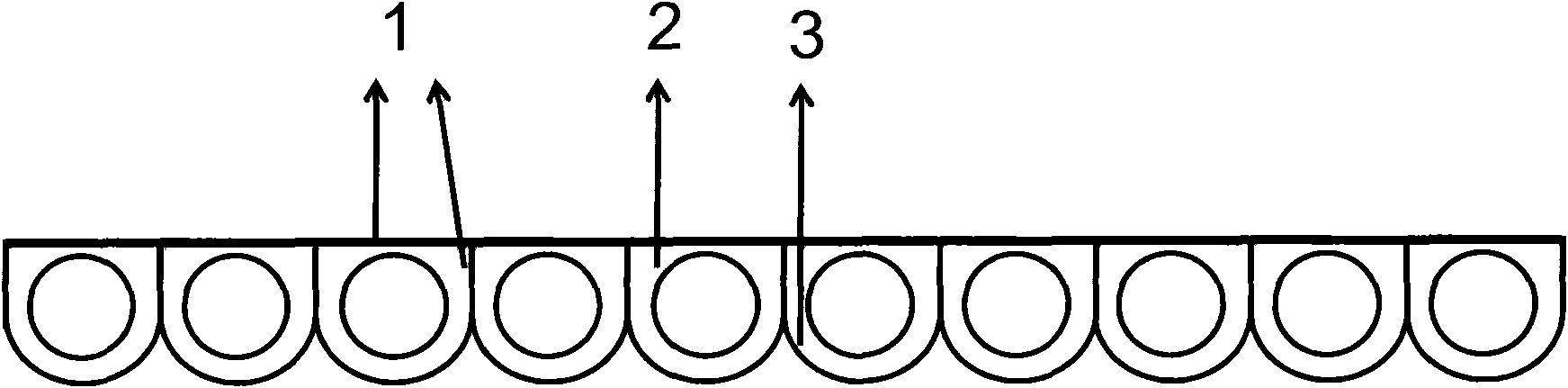

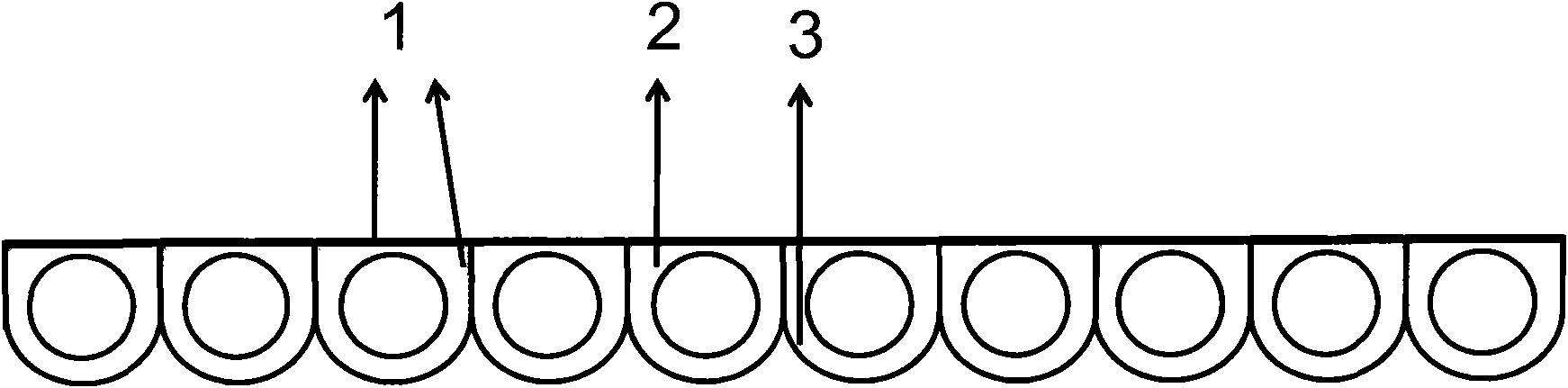

[0021] The structure when the present invention is applied to solar heat collectors is as attached figure 1 As shown, it is a polymer-based solar heat collector, which consists of three parts: a polymer heat collecting tube 1, a polymer glass cover plate 2, and a polymer thermal insulation reflective plate 3. Among them, the polymer glass 2 is polycarbonate glass with a thickness of 1mm, and the light transmittance reaches 85%. Using extrusion molding process. The area size is 800mm×1200mm.

[0022] The polymer heat collecting tube 1 of the present invention is the main component, and is formed by extrusion after adding heat transfer agent, endothermic agent and compatibilizer with polymer resin. The polymer resin is made of PE-RT pipe special material, 100 parts, the heat transfer agent is 10 parts of flake graphite, the heat absorbing agent is 10 parts of carbon black, and the compatibilizer is 5 parts of PE grafted maleic anhydride. The resin matrix, heat transfer agent,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com