Narrow gap weld seam temperature measuring device and method

A technology of temperature measuring device and narrow gap is applied in the field of workpiece heating, which can solve the problems of inconvenient installation and disassembly, time-consuming and laborious, and achieve the effect of simple structure, convenient installation, and easy installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

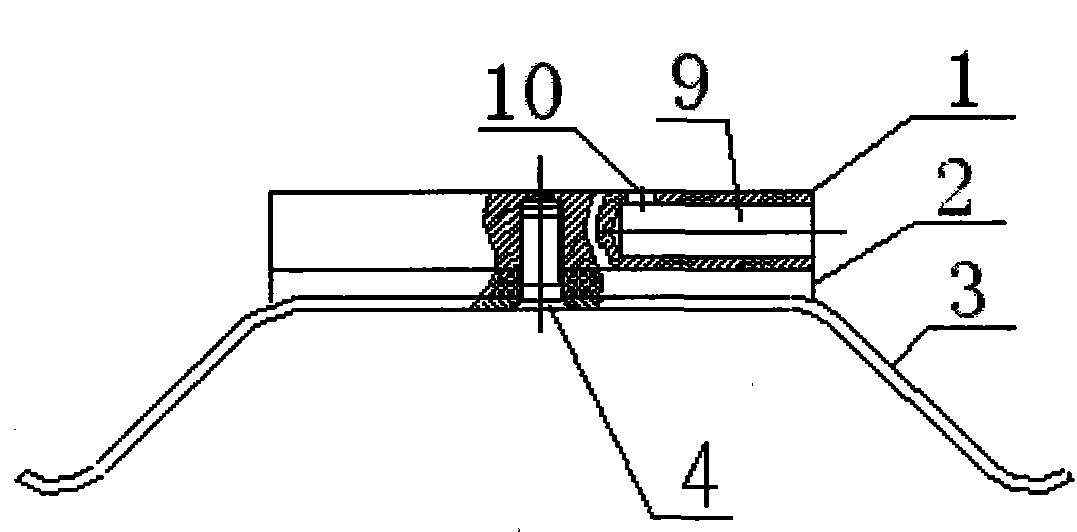

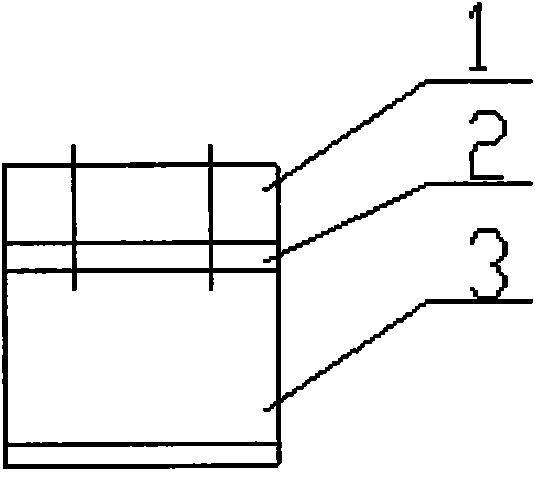

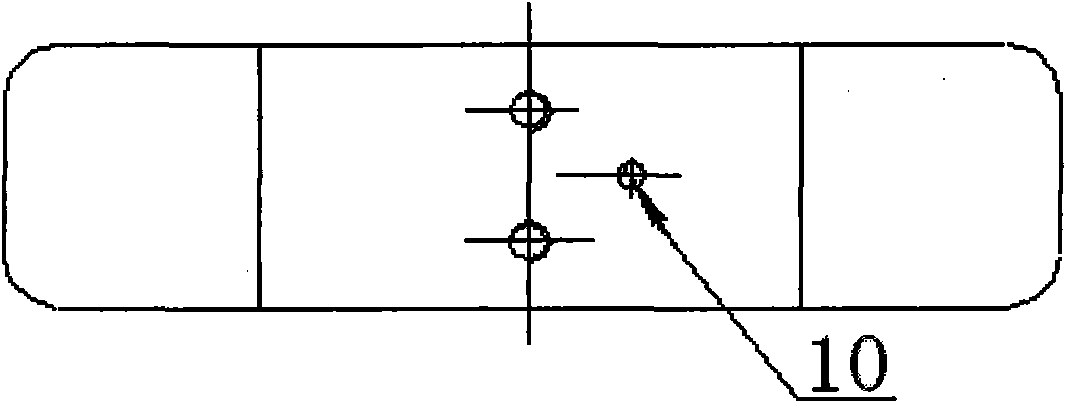

[0033] see Figure 1 to Figure 4 : The temperature measuring device of the present invention comprises a heat conduction block 1, a supporting compression spring sheet 3, a temperature measuring element 5 and a temperature recording instrument. The heat conduction block 1 is a copper block with excellent thermal conductivity, which can ensure that the real-time temperature of the weld zone is consistent with the temperature of the workpiece body during the heating process of the workpiece. The structure of supporting and compressing the spring sheet 3 is very simple, which is a bow-shaped structure, which is convenient for installation and disassembly, and is also beneficial for expansion and contraction in the weld seam. The heat conduction block 1 is just arranged on the top of the support compression spring sheet 3, and a heat insulation layer 2 is arranged between the heat conduction block 1 and the support compression spring sheet 3. The heat insulation layer 2 is asbesto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com